Liquid-cooling device of high-power self-coupling transformation rectifier for civil aircraft

An autotransformer, cooling device technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problem of increasing the volume occupied by external liquid cooling pipes, increasing the volume of internal liquid cooling pipes, Increase the difficulty of design and processing to achieve the effect of simple structure, improved power-to-weight ratio, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

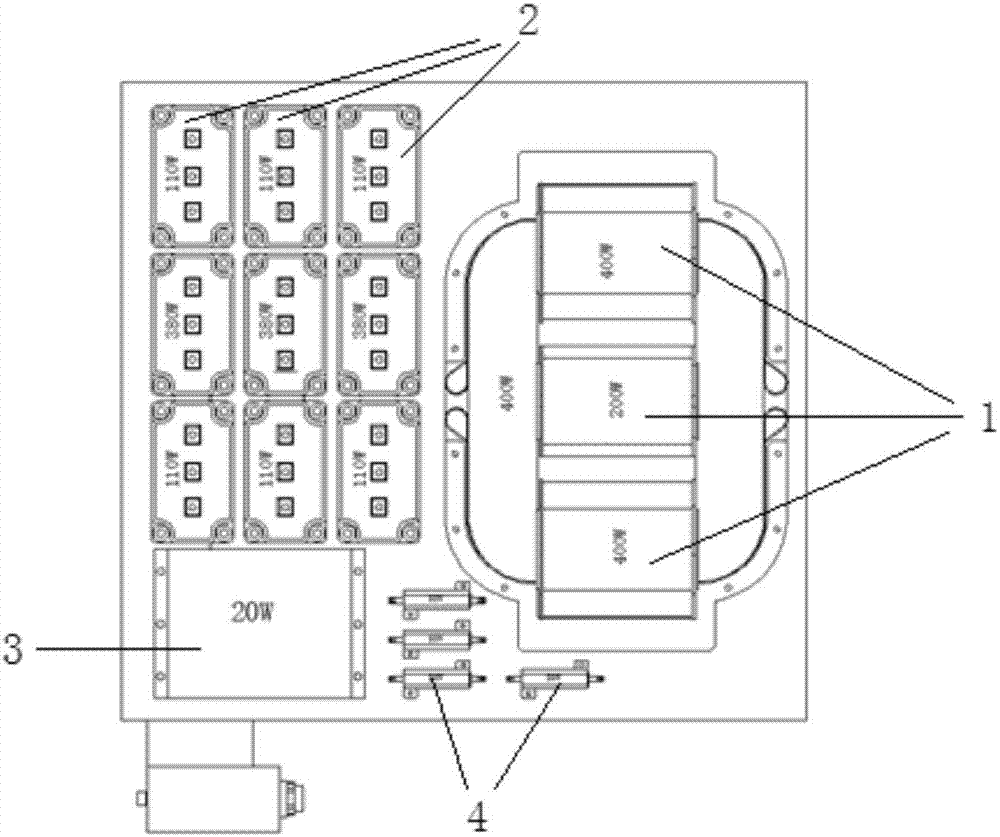

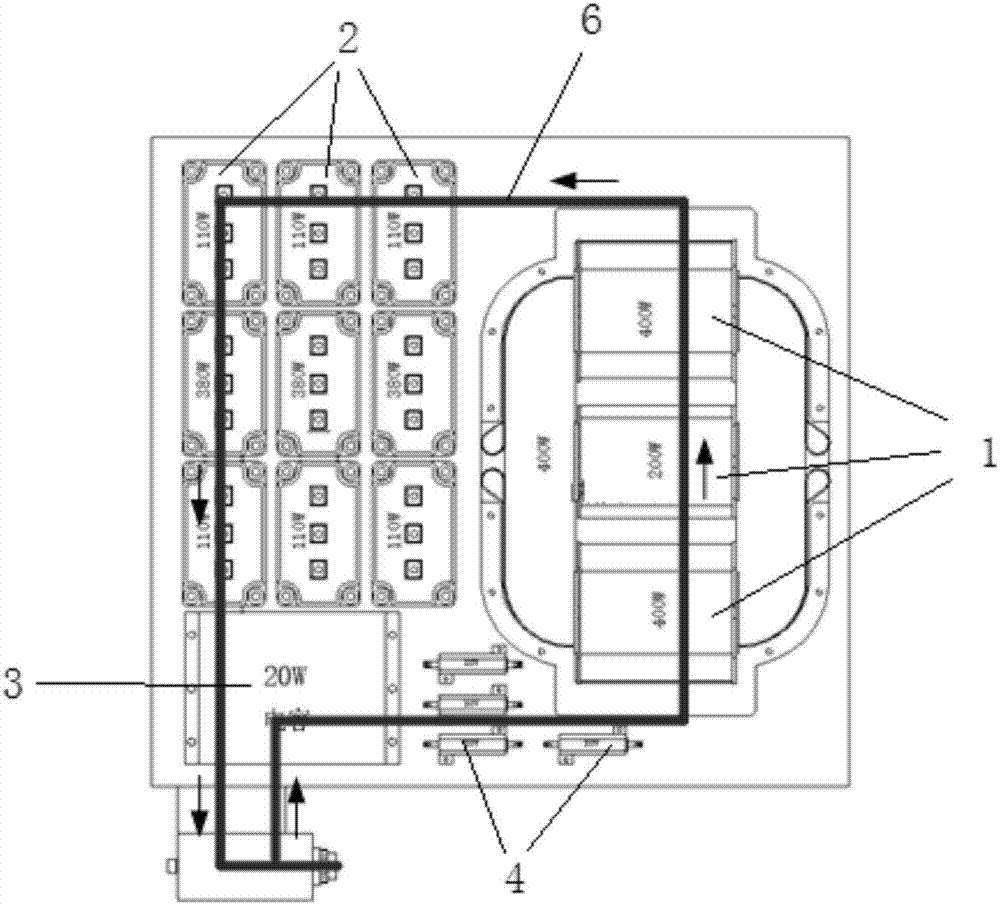

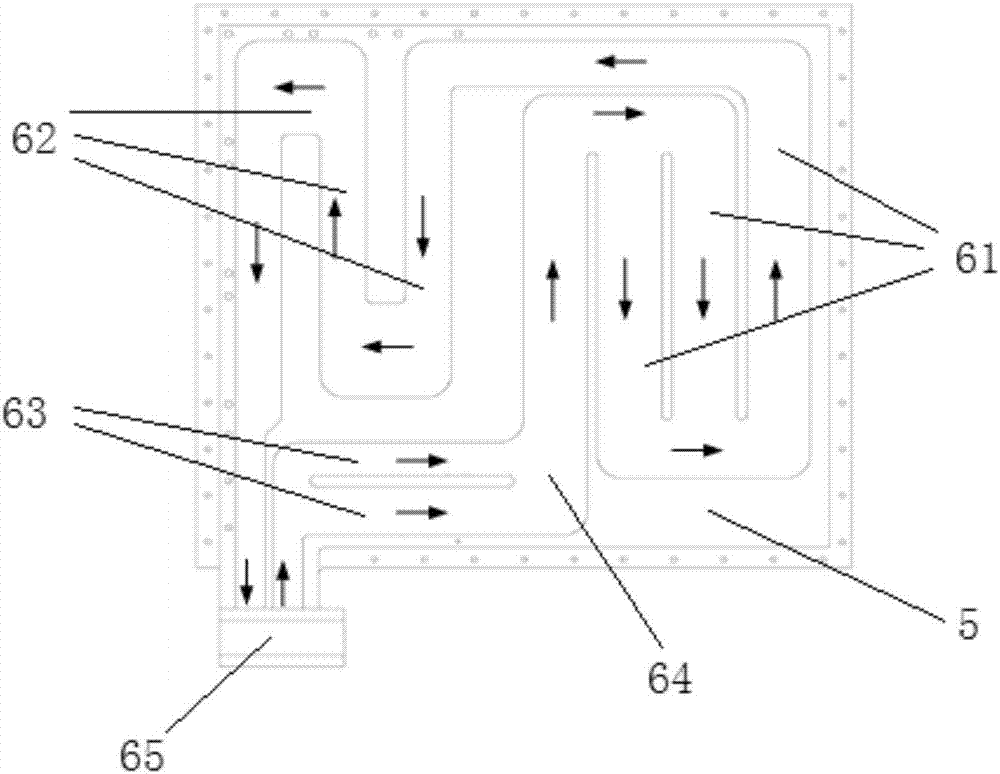

[0021] like Figure 1-3 As shown, the embodiment of the present invention is a liquid-cooled cooling device for a high-power autotransformer rectifier of a civil aircraft, including a liquid-cooled backplane 5 and a liquid-cooled flow channel 6; A transformer 1, a rectifier bridge 2, a capacitor 3, and a resistor 4; the heating component is arranged on one side of the liquid-cooled backplane 5; the liquid-cooled flow channel 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com