A kind of resin desorption liquid treatment method based on electrodialysis technology

A disposal method, electrodialysis technology, which is applied in the field of resin desorption liquid disposal based on electrodialysis technology, to achieve the effects of reducing production costs, high recovery salt income, and reducing the difficulty of subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

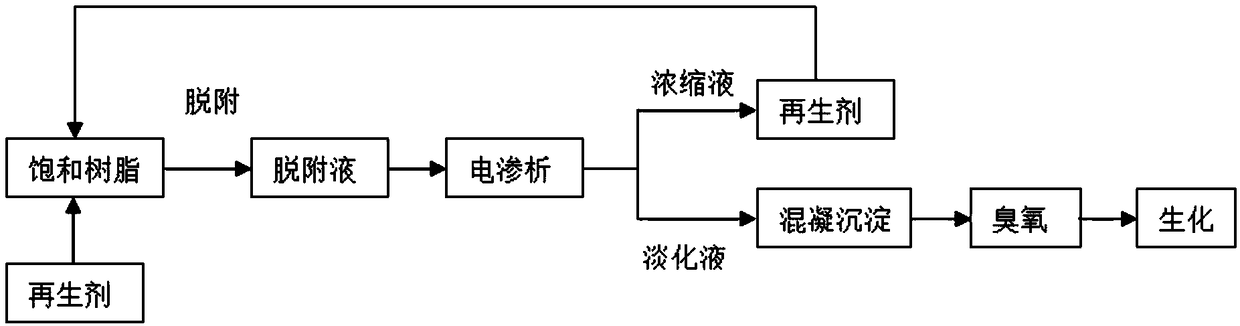

[0033] A kind of resin desorption solution treatment method based on electrodialysis technology of the present embodiment comprises the following steps:

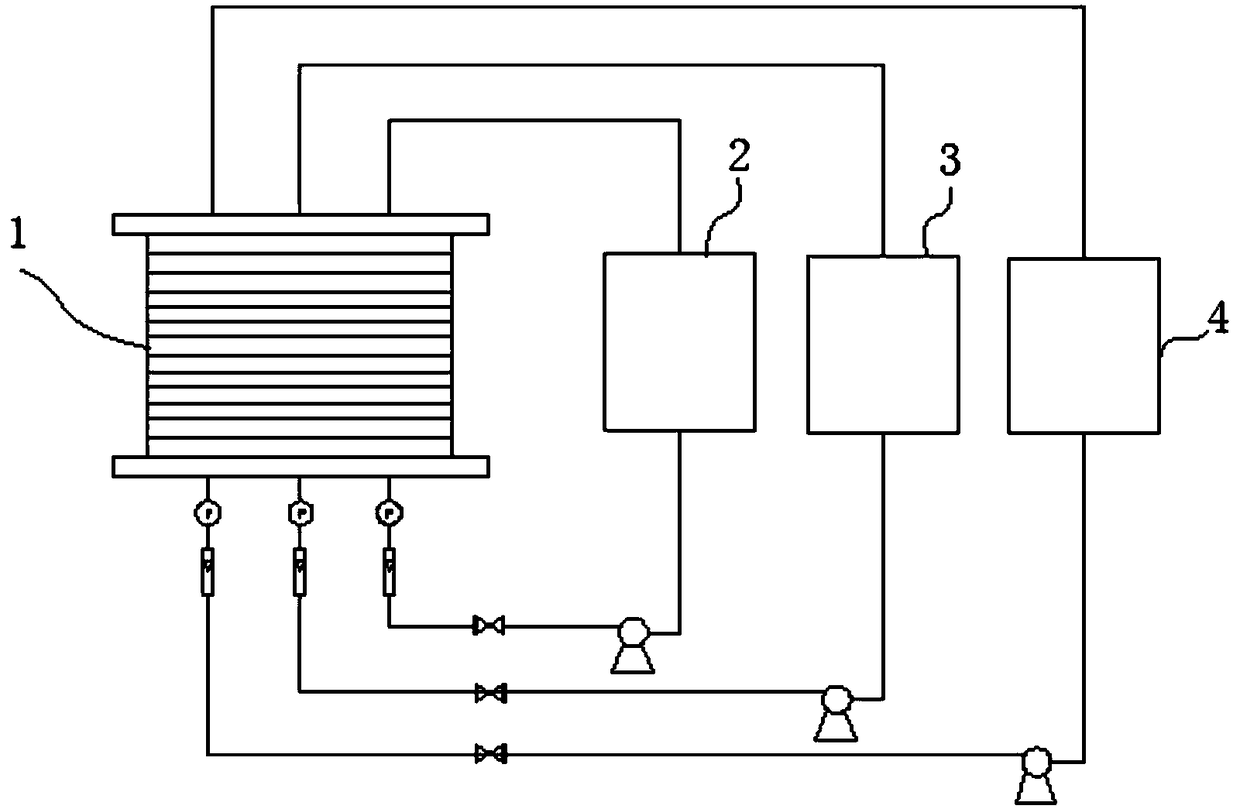

[0034] Step 1, add the stock solution of desorption solution to the desalination chamber 3 of the electrodialysis device: wherein the electrodialysis device includes a steady flow power supply, an electrode, a membrane stack 1, an electrode chamber 2, a desalination chamber 3 and a concentration chamber 4, the electrode chamber 2, the desalination chamber Both chamber 3 and concentration chamber 4 are provided with water inlet and water outlet, and the water inlet pipes of electrode chamber 2, desalination chamber 3 and concentration chamber 4 are provided with flow meters and pressure gauges. The function of the motor is to provide an electric field, including the anode and cathode, wherein the anode is a titanium-coated ruthenium electrode, and the cathode is a stainless steel plate; the function of the membrane stack 1 is ...

Embodiment 2

[0047] A kind of resin desorption solution treatment method based on electrodialysis technology in this embodiment is basically the same as that in Example 1, the difference is that this embodiment uses the concentrated solution with a salt content of 6.59% in Example 1 as the new receiving solution , empty the desalination chamber 3, add 1.2L desorption solution stock solution, other operations are the same as in Example 1, start the electrodialysis device to react for 32min, and stop the experiment when the conductivity in the concentration chamber 4 reaches 150mS / cm. It can be directly used as a regeneration agent, and its desorption capacity is 92% to 99% of that of fresh desorption liquid.

Embodiment 3

[0049] A kind of resin desorption solution treatment method based on electrodialysis technology of this embodiment is basically the same as embodiment 1, the difference is that in this embodiment, the membrane stack 1 includes 8 pairs of anion and yang membranes, and the total surface area of the membrane stack 1 is 0.0672m 2 Add 1.5L desorption liquid in desalination chamber 3, add 0.3L tap water as receiving liquid in concentrating chamber 4, desorption liquid: receiving liquid=5:1; Electrode liquid adopts the sodium sulfate solution that mass concentration is 3%; The voltage of the dialysis device is 12V, and the voltage of the motor is 2V. After the electrodialysis device starts to react for 60 minutes, the experiment is stopped when the conductivity in the concentration chamber 4 reaches 170mS / cm, and the conductivity of the desalinated solution drops from 120.8mS / cm to 39.5mS / cm. cm, COD of dilute solution Mn is 4629mg / L, the salt content is 1.69%, and the COD of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com