Novel sprue cup

A sprue cup, a new type of technology, applied in the direction of core, casting mold, casting mold composition, etc., can solve the problems of not meeting large-capacity casting, affecting the quality of castings, destroying the structure of castings, etc., to ensure the quality and performance of castings, and convenient Impurities float up, weakening the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

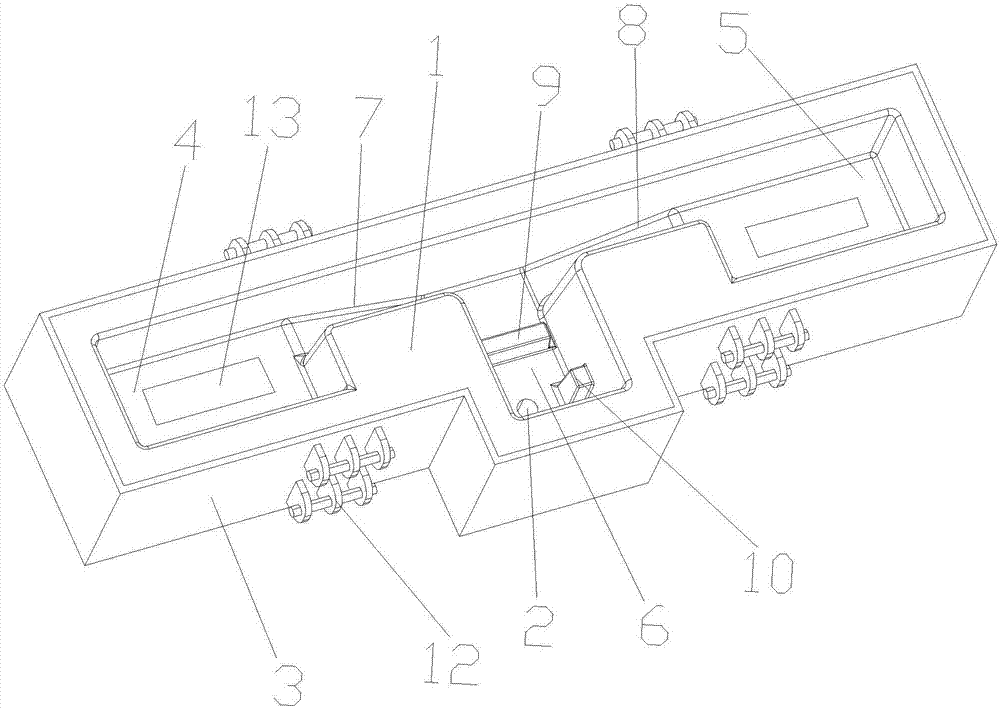

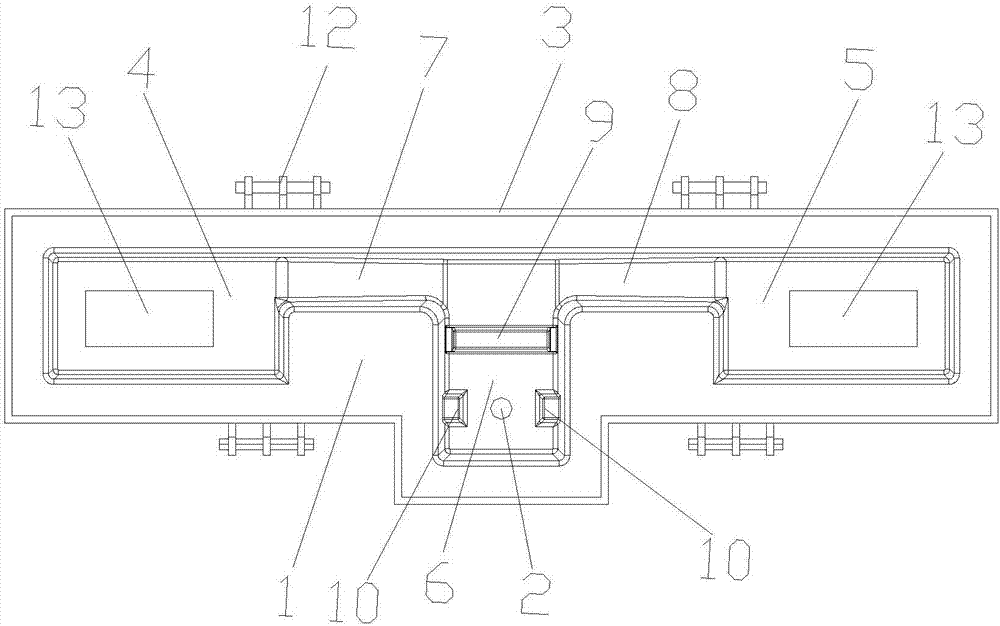

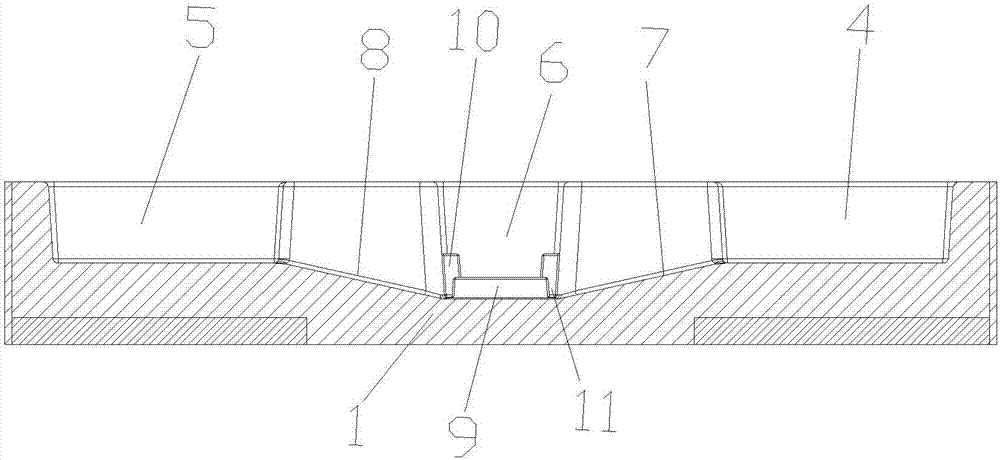

[0019] Such as Figure 1-3 As shown, a new sprue cup includes a body 1, a gate 2, and a sand box 3 wrapped outside the body 1. The outer peripheral wall of the sand box 3 is provided with a hanger 12 for easy hanging. The body 1 includes a symmetrical The provided first pouring chamber 4, the second pouring chamber 5 and the inflow chamber 6 between the first pouring chamber 4 and the second pouring chamber 5, the gap between the first pouring chamber 4 and the inflow chamber 6 There is a first inclined flow channel 7 between them, and a second inclined flow channel 8 is provided between the second pouring cavity 5 and the inflow cavity 6, and the inflow cavity 6 and the first inclined flow channel 7, the second inclined flow channel A cross block 9 is provided at the intersection of the channels 8, and side blocks 10 are provided on both side walls of the inflow chamber 6, and the side blocks 10 are located on both sides of the gate 2 and are on the same straight line as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com