3D printer consumable spray head capable of achieving self-cleaning

A technology of 3D printers and consumable nozzles, which is applied in the field of printers, can solve the problems that affect the printing effect and the nozzles that are easy to block the nozzles, etc., and achieve the effect of continuous operation, stable and reliable cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

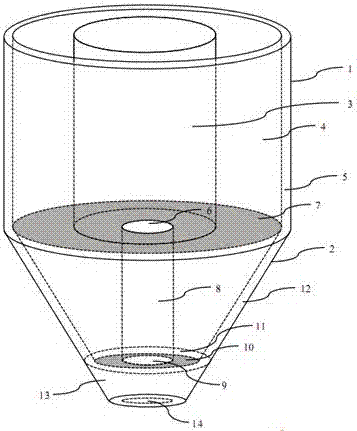

[0023] see figure 1 and 2 , the self-cleaning 3D printer consumable nozzle of the present invention comprises:

[0024] Conduit 1, comprising a first pipeline 3 for introducing consumables used, a second pipeline 4 for heating said consumables, and a third pipeline 5 for introducing cleaning liquid or gas;

[0025] The nozzle 2 has a frustum-shaped cavity and a spout 14 . The nozzle 2 is located at the lower end of the conduit 1 and has a first partition 7 . The nozzle 2 has two layers of tube walls, and a fourth pipeline 12 for introducing cleaning liquid or gas is formed between the two layers of tube walls, and the fourth pipeline 12 communicates with the third pipeline 5 .

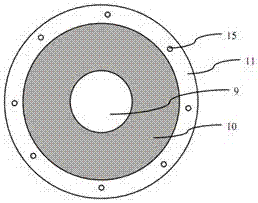

[0026] The delivery pipe 8, below the partition 7, communicates with the first pipeline 3 through the through hole 6 on the first partition, and the consumable output port 9 of the delivery pipe 8 is at the nozzle Above 14, the lower end surface of the feeding pipe 8 has a second partition 10, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com