Diagonal-bracing type clamping mechanism and climbing robot suitable for rod-shaped object

A clamping mechanism and diagonal brace technology, which is applied in the field of climbing robots, can solve problems such as shaking, large vibration amplitude, low climbing efficiency, and no pole-shaped object climbing robot clamping mechanism, etc., to achieve stable clamping tight, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

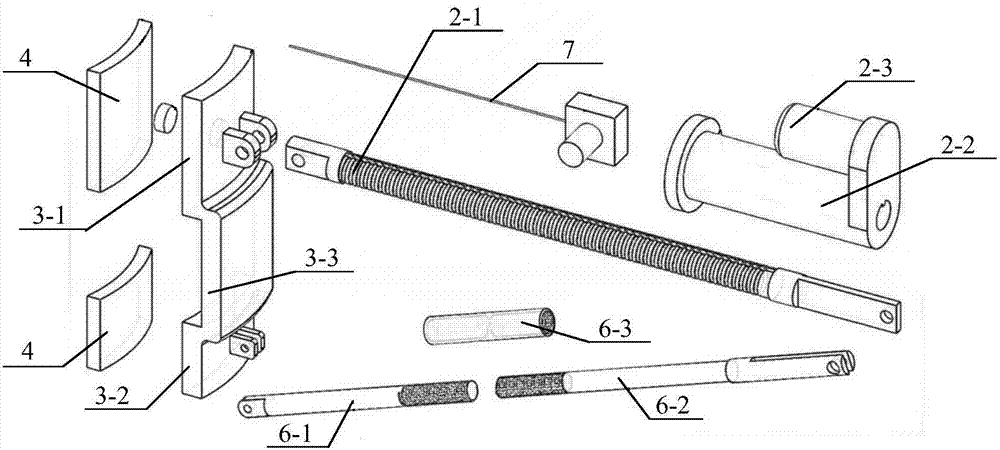

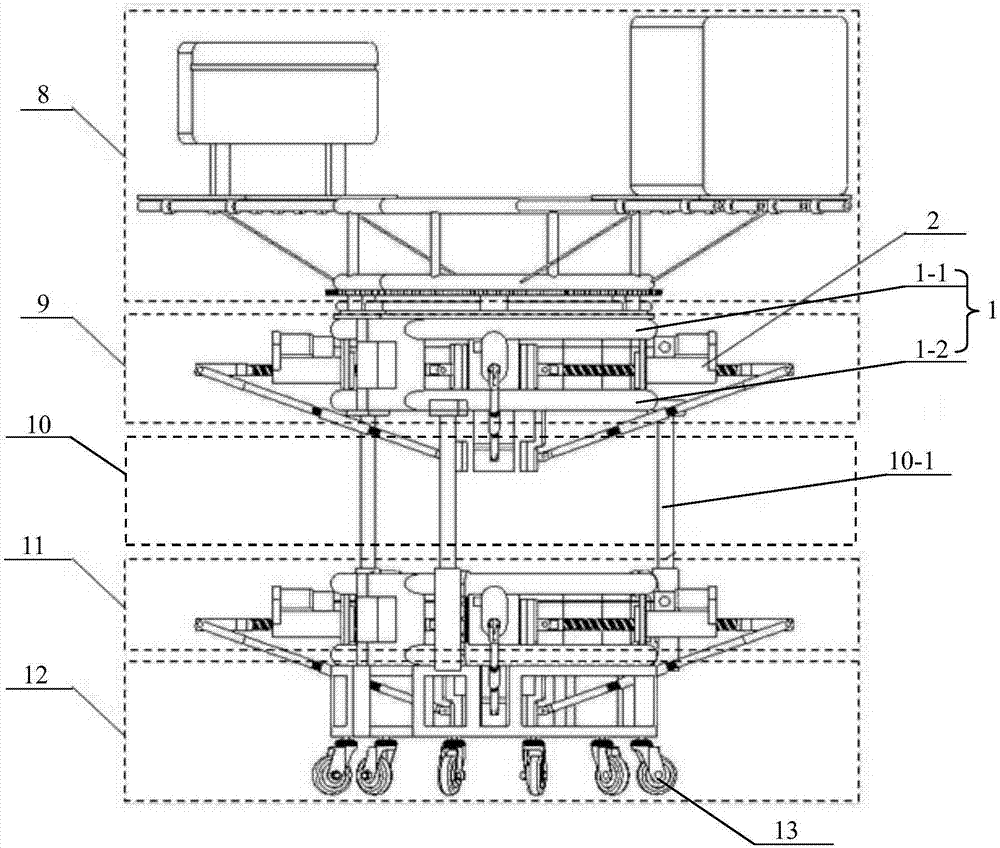

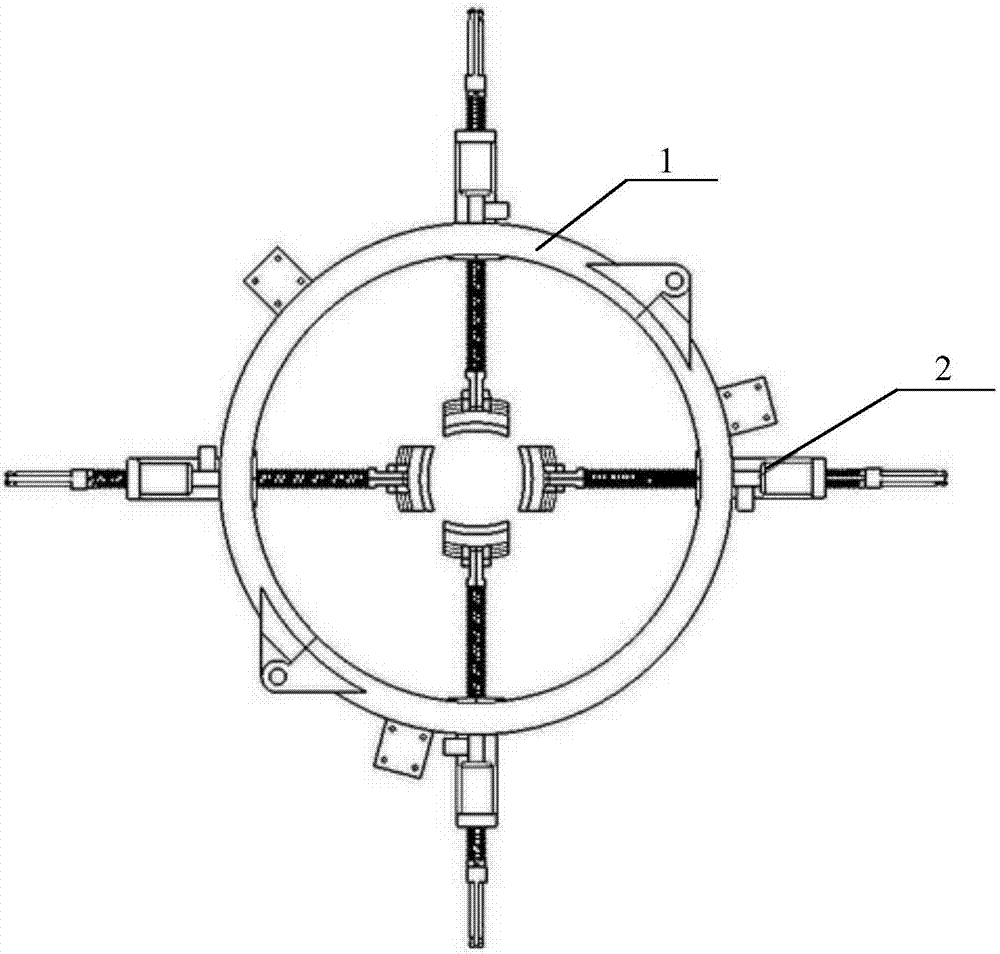

[0031] On the one hand, the present invention provides a kind of brace type clamping mechanism, such as Figure 1-5 As shown, it includes an openable and closable annular body 1 for being sleeved on a rod-shaped object to be climbed. Specifically, the annular body is composed of two parts of semi-circular buckles, and bolts are used at the interface of the two semi-circular rings. Or screw connection, then fixed with a fixed plate, or using conventional technical means in the field, all do not affect the implementation of the present invention, a number of clamping units 2 are uniformly arranged on the annular body 1 along the circumferential direction, and each clamping unit 2 includes Elevator body 2-2, elevator screw rod 2-1 and drive motor 2-3, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com