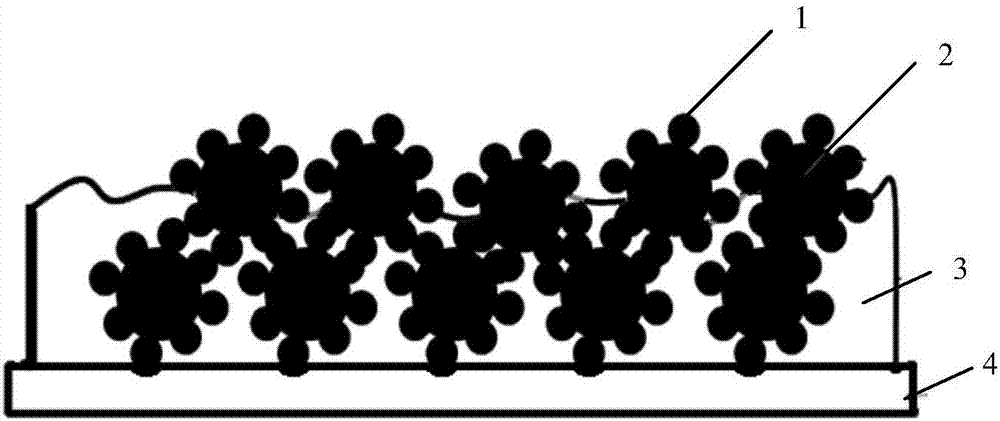

Super-hydrophilic, self-cleaning and antifogging coating and preparation method thereof

An anti-fog coating, self-cleaning technology, applied in coatings, polyurea/polyurethane coatings, alkali metal silicate coatings, etc., can solve the self-cleaning, anti-fogging effect and durability or preparation of super-hydrophilic coatings Problems such as unsatisfactory conditions, harsh preparation conditions, and limited application scope have achieved the effect of overcoming the harsh preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The super-hydrophilic self-cleaning anti-fog coating of the present embodiment 1 is prepared by the following method, and the steps are as follows:

[0025] (1) Add 12ml tetraethyl orthosilicate to a three-necked flask, add 400ml ethanol and 30ml 25% ammonia solution under stirring, react at 60°C for 8h to obtain silica particles with a particle size of 80nm, and then Add 3-aminopropyltrimethoxysilane whose mass is 1 / 3 of the tetraethyl orthosilicate, and react at 50°C for 6 hours under stirring, so that the surface of the silica particles is grafted with a sufficient amount of 3-aminopropyl Trialkoxysilane, centrifuged and ultrasonically washed to obtain aminosilane-modified nanoparticles;

[0026] (2) Add the 10 g of aminosilane-modified nanoparticles in 50 ml of absolute ethanol, and after the ultrasonic dispersion is uniform, slowly add 50 g of AkzoNobel’s silica sol Levasil CC151 (solid content 15%, 5 nm) dropwise under stirring, After reacting for 24 hours, a sta...

Embodiment 2

[0029] The superhydrophilic self-cleaning anti-fog coating of the present embodiment 2 is prepared by the following method, and the steps are as follows:

[0030] (1) Add 12ml of tetraethyl orthosilicate to a three-necked flask, add 400ml of ethanol and 30ml of 25% ammonia solution under stirring and react at 60°C for 10h to obtain silica particles with a particle size of 100nm, and then add 3-aminopropyltrimethoxysilane whose mass is 1 / 2 of the tetraethyl orthosilicate, reacted at 50°C for 6 hours under stirring, so that the surface of the silica particles was grafted with a sufficient amount of 3-aminopropyltrimethoxysilane Oxysilane, centrifuged, and ultrasonically washed to obtain aminosilane-modified nanoparticles;

[0031] (2) Add the 10g of aminosilane-modified nanoparticles in 50ml of absolute ethanol, and after the ultrasonic dispersion is uniform, slowly add 30g of Akzo Nobel's Levasil CC301 (solid content 28%, 7nm) dropwise under stirring state, add the Adjust the ...

Embodiment 3

[0034] The superhydrophilic self-cleaning anti-fog coating of present embodiment 3 is prepared by the following method, and its steps are as follows:

[0035](1) Add 12ml of tetraethyl orthosilicate to a three-necked flask, add 400ml of ethanol and 30ml of 25% ammonia solution under stirring and react at 60°C for 10h to obtain silica particles with a particle size of 100nm, and then add 3-aminopropyltrimethoxysilane whose mass is 1 / 2 of the tetraethyl orthosilicate, reacted at 50°C for 6 hours under stirring, so that the surface of the silica particles was grafted with a sufficient amount of 3-aminopropyltrimethoxysilane Oxysilane, centrifuged, and ultrasonically washed to obtain aminosilane-modified nanoparticles;

[0036] (2) Add the 10g of aminosilane-modified nanoparticles in 50ml of absolute ethanol, after the ultrasonic dispersion is uniform, slowly add 20g of AkzoNobel's Levasil CC401 (solid content 37%, 12nm) dropwise under stirring state, add Adjust the solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com