A kind of superhydrophilic functional coating based on cage polysilsesquioxane and preparation method thereof

A technology of polysilsesquioxane and secondary aminosiloxane, which is applied in the field of superhydrophilic materials, can solve problems such as inability to guarantee long-term performance, resistance to wiping and solvents, and limited application range, and achieve simple, fast and quick preparation , Overcoming harsh preparation conditions and overcoming technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

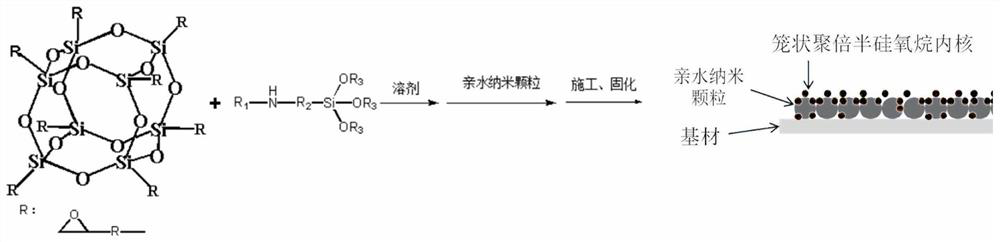

[0038] A kind of preparation method of the superhydrophilic functional coating based on cage polysilsesquioxane of the present invention, described preparation method comprises the following steps:

[0039] Add a certain amount of epoxy-based cage polysilsesquioxane into the container, then add a certain amount of solvent, add 8 times the molar ratio of secondary aminosiloxane under stirring, and wait for a period of time after reaction. The main resin with alkoxy groups prepared by the reaction of cage polysilsesquioxane and secondary aminosiloxane; add hydrophilic nano-silica to the container, and stir well to obtain a cage-based polysilsesquioxane The precursor solution of the super-hydrophilic functional coating of alkane; the precursor solution is coated on the surface of the substrate, and reacted for 24 hours at room temperature to obtain the super-hydrophilic functional coating.

[0040] The superhydrophilic coating of the present invention can be applied to glass, sta...

Embodiment 1

[0042] Add 60g of ethanol to a 500ml two-necked flask, and add glycidyl etheroxypropyl cage polysilsesquioxane under stirring 6g, then add 9.8g N-n-butyl-3-aminopropyltrimethoxysilane, add Evonik hydrophilic silica 33g ( 200), after stirring evenly, a precursor solution with a solid content of about 45% was obtained.

[0043]The precursor is easily coated on the surface of the substrate by spraying, and the super-hydrophilic coating is obtained after curing at room temperature for 24 hours. The water contact angle of the super-hydrophilic coating has been tested to be 4°.

Embodiment 2

[0045] Add 200g of ethanol to a 500ml two-necked flask, and add glycidyl etheroxypropyl cage polysilsesquioxane under stirring 5g, then add 7.6g 3-(phenylamino) propylmethoxysilane, add Evonik hydrophilic silica 63g ( 380), and after stirring evenly, a precursor solution with a solid content of about 27% was obtained.

[0046] The precursor is easily coated on the surface of the substrate by spraying, and the super-hydrophilic coating is obtained after curing at room temperature for 24 hours. The water contact angle of the super-hydrophilic coating is detected to be 3°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com