Soybean small peptide, preparation method and applications thereof

A technology of soybean small peptides and microbial strains, applied in the biological field, can solve the problems of osmotic pressure imbalance in the body, excessive intake of nutrients, etc., achieve low fishy smell, strong protein decomposition ability, and improve the effect of comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

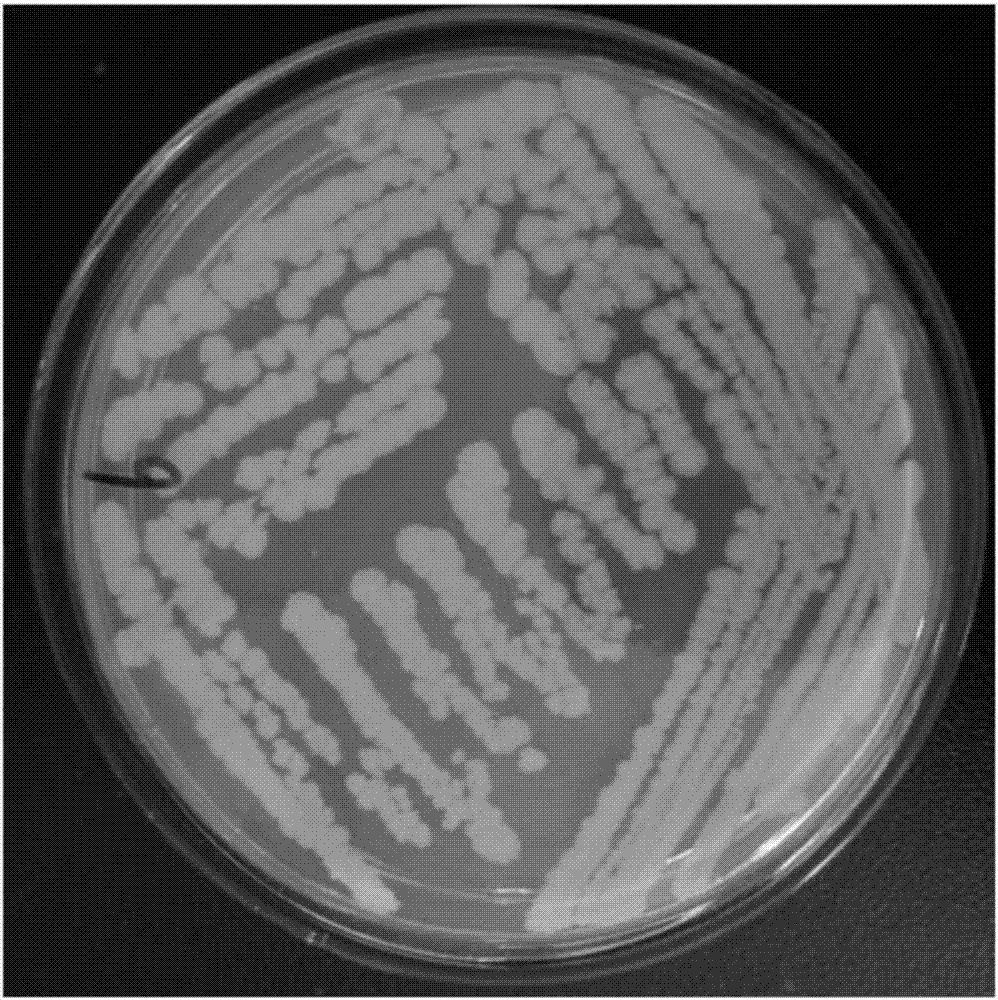

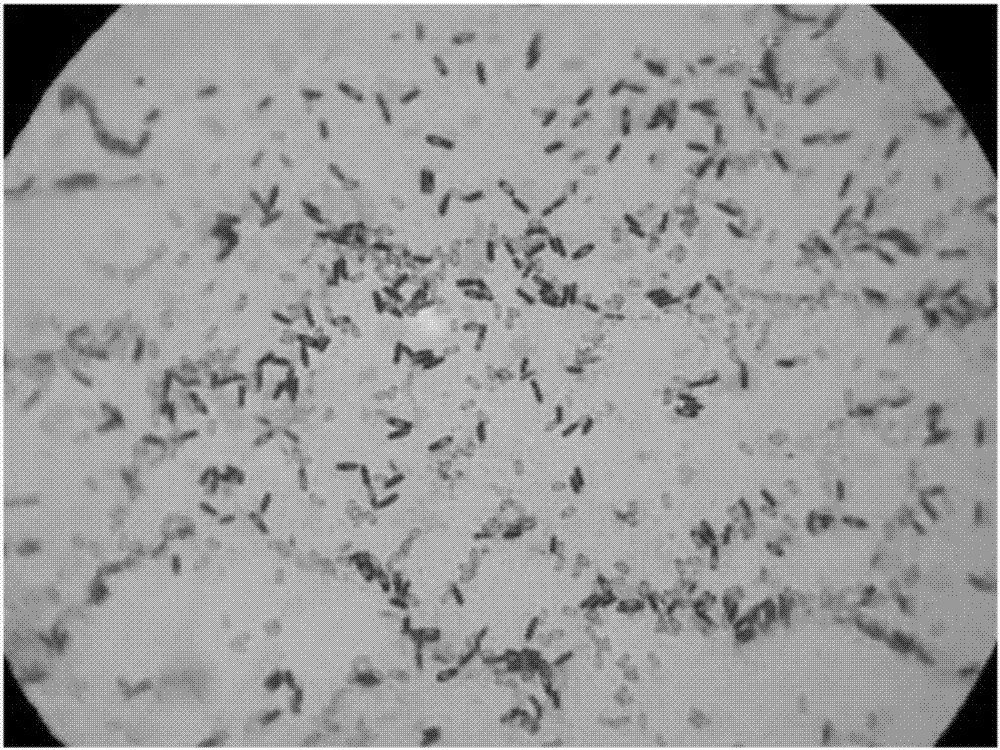

[0043] Embodiment 1. Isolation, characterization, cultivation and preservation of Bacillus cereus of the present invention

[0044] 1.1 Strain isolation

[0045] Weigh 10g of tempeh powder into a 250mL Erlenmeyer flask, add 100mL of sterile normal saline, shake for 2-4 hours, settle still to obtain the supernatant, take out 10mL for dilution, and dilute the bacterial solution to 10 -7 , take 10 respectively -1 、10 -3 、10 -3 、10 -7 These several gradients were subjected to plate coating experiments, spread on casein medium, and cultured at 37°C for 24 hours to observe whether a transparent circle was produced. Pick 9 single colonies that produce transparent circles, streak them in the separation medium, purify the strains, and finally preserve the 9 strains on the slant, and then carry out the enzyme activity test. According to the size of the transparent circle and the size of the enzyme activity, the bacterial strain with the highest enzyme activity is selected, that is,...

Embodiment 2

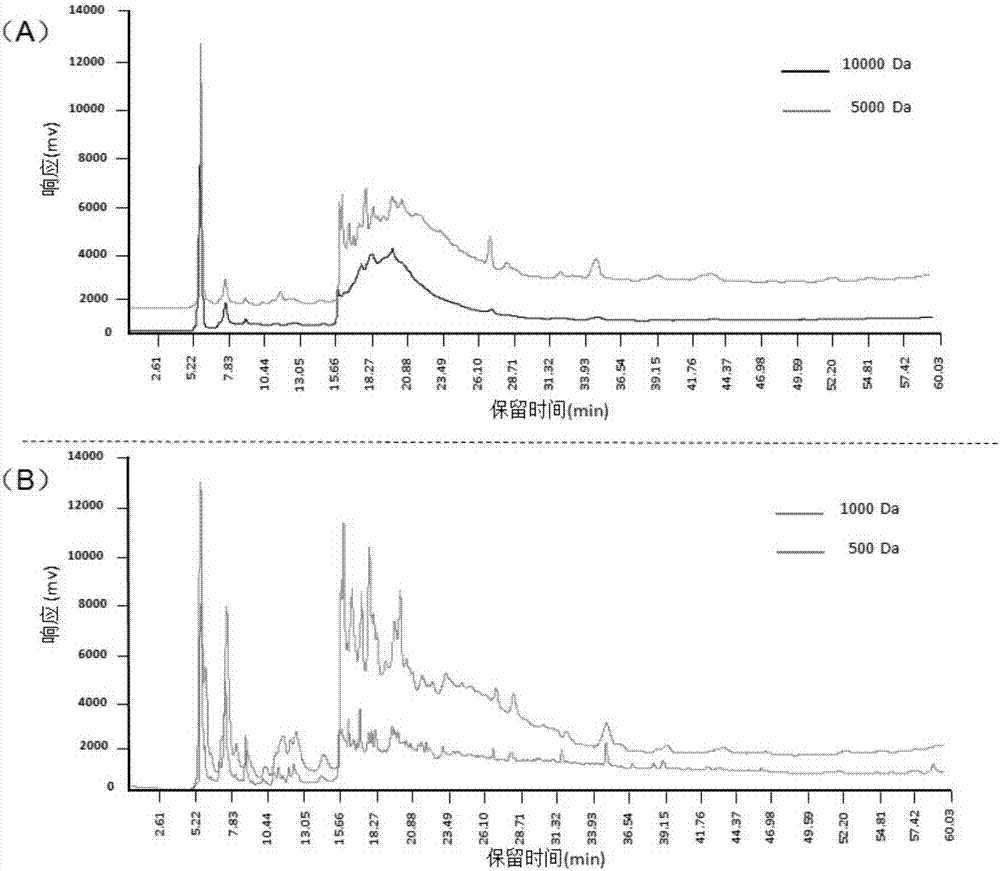

[0069] Embodiment 2. Preparation of soybean small peptide

Embodiment 21

[0071] Soy small peptides are prepared according to the following steps:

[0072] (a) Weighing the twice-soaked soybean meal, adding water, autoclaving, inoculating the Bacillus cereus of the present invention and fermenting in a fermenter for 72 hours in an airtight manner;

[0073] (b) add water to the fermented soybean meal obtained in step (a), add thermolysin (thermolysin) to carry out enzymolysis after being fully infiltrated, and then ultrasonically extract to obtain an enzymolysis solution, and the amount of thermolysin is 5 ‰ mass parts (g / kg);

[0074] (c) Pass the obtained enzymatic solution in step (b) through a 400-mesh filter cloth to remove particulate matter, add activated carbon and Florisil and let it stand for half an hour to purify, then filter through a plate and frame filter press to remove activated carbon and Florisil Silica, to obtain debitter deodorization and partly decolorized soybean protein serum, the consumption of gac and florisil is 5‰ and 5‰ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com