A kind of production technology of fermented japonica rice yuan red wine in a large tank

The invention relates to a production process and a technology for fermenting japonica, which is applied in the field of production technology of large-tank fermented japonica rice wine, which can solve the problems of fermentation rancidity, reducing the amount of feeding materials, low acidity, etc., and achieves the purpose of preventing fermented mash, inhibiting the growth of miscellaneous bacteria, and having a refreshing taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

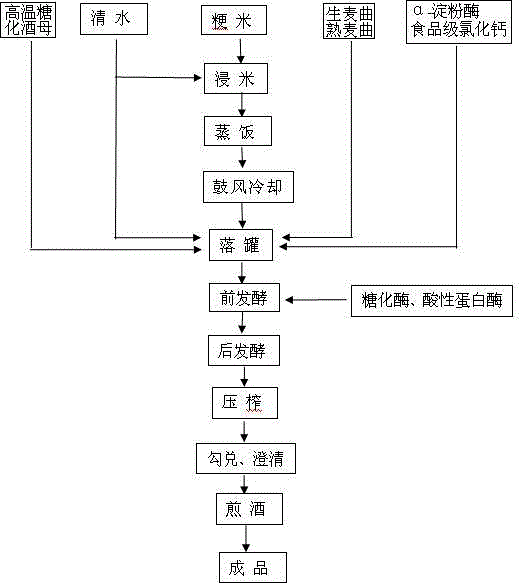

[0032] The production technology of large-tank fermented japonica rice yuan red wine of the present invention comprises the following steps:

[0033] A1 Rice soaking: Weigh 100kg of japonica rice, after screening and removing impurities, put it into a tank and add water for soaking, the water surface is 10 cm above the rice layer, soak for 6 hours, and drain;

[0034] A2 Steaming and cooling: steam the japonica rice until there is no white heart inside, loose and not mushy, cooked but not rotten and uniform; quickly cool the steamed japonica rice to the required temperature, and the temperature is to control the temperature of the product after it is dropped into the tank It is advisable to be 24 ~ 28 ℃;

[0035] A3 into the tank: Japonica rice, 145kg of water, 12kg of high-temperature saccharified distiller's mother, 10kg of raw wheat koji, 6kg of cooked wheat koji, 20g of α-amylase of 4000U, CaCl 2 Mix 15g of ≥90% food-grade calcium chloride evenly, and control the product ...

Embodiment 2

[0045] The production technology of large-tank fermented japonica rice yuan red wine of the present invention comprises the following steps:

[0046] A1 Rice soaking: Weigh 100kg of japonica rice, after screening and removing impurities, put it into a tank and add water for soaking, the water surface is 6 cm above the rice layer, soak for 4 hours, and drain;

[0047] A2 Steaming and cooling: steam the japonica rice until there is no white heart inside, loose and not mushy, cooked but not rotten and uniform; quickly cool the steamed japonica rice to the required temperature, and the temperature is to control the temperature of the product after it is dropped into the tank It is advisable to be 24 ~ 28 ℃;

[0048] A3 into the tank: japonica rice, 135kg of water, 10kg of high-temperature saccharified distiller's mother, 9kg of raw wheat koji, 5kg of cooked wheat koji, 4000U of α-amylase 40g, CaCl 2 Mix 25g of ≥90% food-grade calcium chloride evenly, and control the product tempera...

Embodiment 3

[0058] The production technology of large-tank fermented japonica rice yuan red wine of the present invention comprises the following steps:

[0059] A1 Rice soaking: Weigh 100kg of japonica rice, after screening and removing impurities, put it in a tank and add water for soaking, the water surface is 8 cm above the rice layer, soak for 5 hours, and drain;

[0060] A2 Steaming and cooling: steam the japonica rice until there is no white heart inside, loose and not mushy, cooked but not rotten and uniform; quickly cool the steamed japonica rice to the required temperature, and the temperature is to control the temperature of the product after it is dropped into the tank It is advisable to be 24 ~ 28 ℃;

[0061] A3 into the tank: japonica rice, 140kg of water, 11kg of high-temperature saccharified distiller's mother, 9.5kg of raw wheat koji, 5.5kg of cooked wheat koji, 30g of 4000U α-amylase, CaCl 2 Mix 20g of ≥90% food-grade calcium chloride evenly, and control the product tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com