Test method of crystal optical uniformity and detection device thereof

A technology of crystal optics and testing methods, which is applied to the measurement of phase-influenced characteristics and polarization-influenced characteristics. It can solve the problems of low qualified rate of finished products, waste of precision processing work, and reduced efficiency. It achieves simple methods, reduces detection costs, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, this embodiment provides the test method of crystal optical uniformity

[0027] This embodiment is tested based on the following principles. The incident light emitted by a collimated linearly polarized coherent light source is incident on the crystal to be tested through detection polishing. By adjusting the polarization direction of the light source and the crystal axis (perpendicular to the incident light The axis of the crystal axis) position relationship, through the analysis of polarized interference imaging in the direction of the crystal axis of the crystal to be measured, can characterize the crystal optical uniformity (refractive index uniformity) in the direction of the crystal axis. The test method of the optical uniformity of the crystal provided in the embodiment.

[0028] First, use a device that can emit coherent light, such as a laser or a monochromator, to collimate and polarize the coherent light source emitted by the laser or a monochro...

Embodiment 2

[0032] Embodiment 2, this embodiment provides a detection device for the optical uniformity of the crystal prepared by the method provided in Embodiment 1.

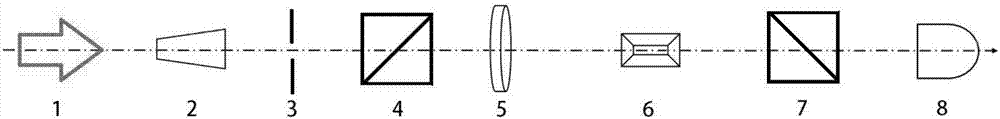

[0033] As shown in Figure 1, the detection device for crystal optical uniformity provided in this embodiment includes a coherent light source emitter 1, a collimator 2, a polarizer 4, a phase retarder 5, a crystal placement table 6, As the analyzer 7 and the imaging receiving device 8 are common optical instruments, in this embodiment, only their function in detecting the optical uniformity of the blank crystal will be described.

[0034] The coherent light source transmitter 1 is used to emit a light source. More specifically, the coherent light source transmitter is a device capable of emitting coherent light such as a laser or a monochromator device. The main reason for using the coherent light source transmitter is that the coherent light source can be used to obtain clear Accurate polarization interference image, mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com