Novel mechanical type orchard spraying machine

A mechanical, sprayer technology, applied in the device, application, animal husbandry, etc. of catching or killing insects, can solve the problems of difficulty in pest control, increased labor intensity, rolling water droplets, unfavorable orchard ground management, etc. Achieve the effect of alleviating the tension of rural labor force, improving the degree of automation, and suitable for popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

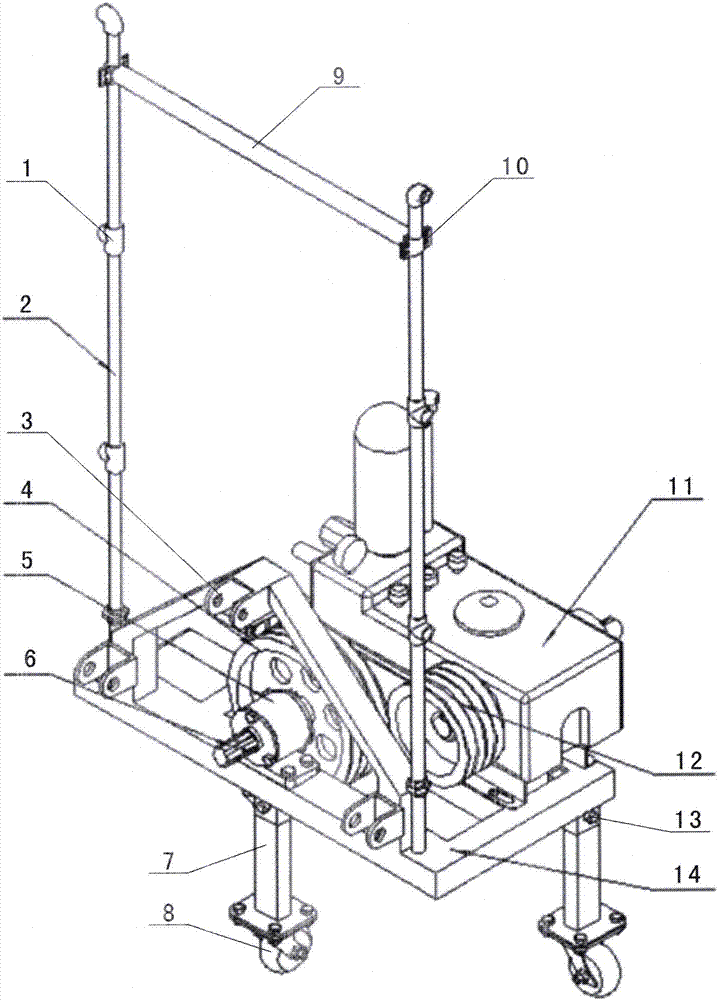

[0022] Such as figure 1 As shown, the spray rod 2 is fixedly installed on the frame 14, the spray rod 2 and the plunger pump 11 are connected by a hard liquid pipe, and the spray head 1 on the spray rod 2 can rotate laterally. This installation method is simple in structure and low in cost, but the control is not convenient enough, and the angle of the spray head needs to be manually adjusted.

Embodiment 2

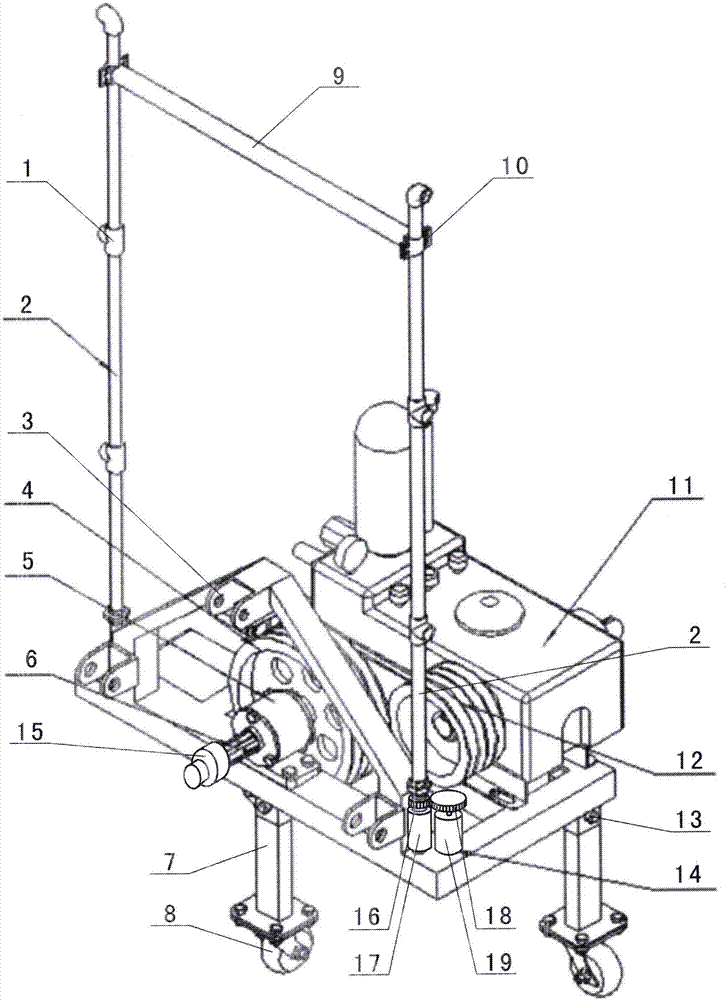

[0024] Such as figure 2 As shown, the bottom of the spray bar 2 is installed on the frame 14 by the spray bar bearing 17, and the position above the spray bar bearing 17 on the spray bar 2 is provided with a driven gear 16, and a stepper motor 19 is installed on the frame 14, A driving gear 18 is set on the rotating shaft of the stepping motor 19, and the driving gear 18 is meshed with the driven gear 16. The spray rod 2 and the plunger pump 11 are connected by a soft liquid pipe to meet the requirement that the spray rod 2 can rotate. Requirement, the control input end of stepper motor 19 is connected with motor controller (not shown in the figure, because it is connected by wire, so can operate remotely) by wire; The rotary power input end of input shaft 6 is equipped with clutch 15, and clutch The control input end of 15 is connected with clutch controller (not shown in the figure), and clutch 15 can be manual clutch, and then its control input end is connected with descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com