A kind of method adopting bread machine to make bread

A bread machine and bread technology, which is applied in the direction of toasting equipment, applications, kitchen utensils, etc., can solve the problems of porous and fluffy dough, hard bread, poor elasticity ratio, etc., and achieve the effect of shortening the fermentation time and increasing the degree of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 8

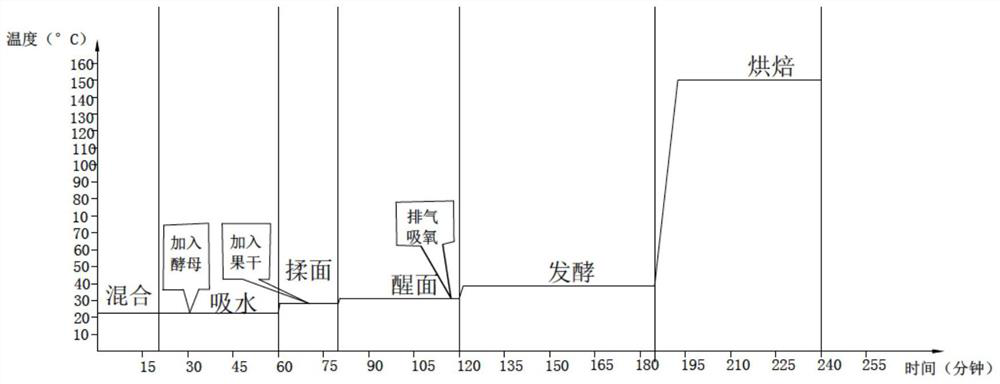

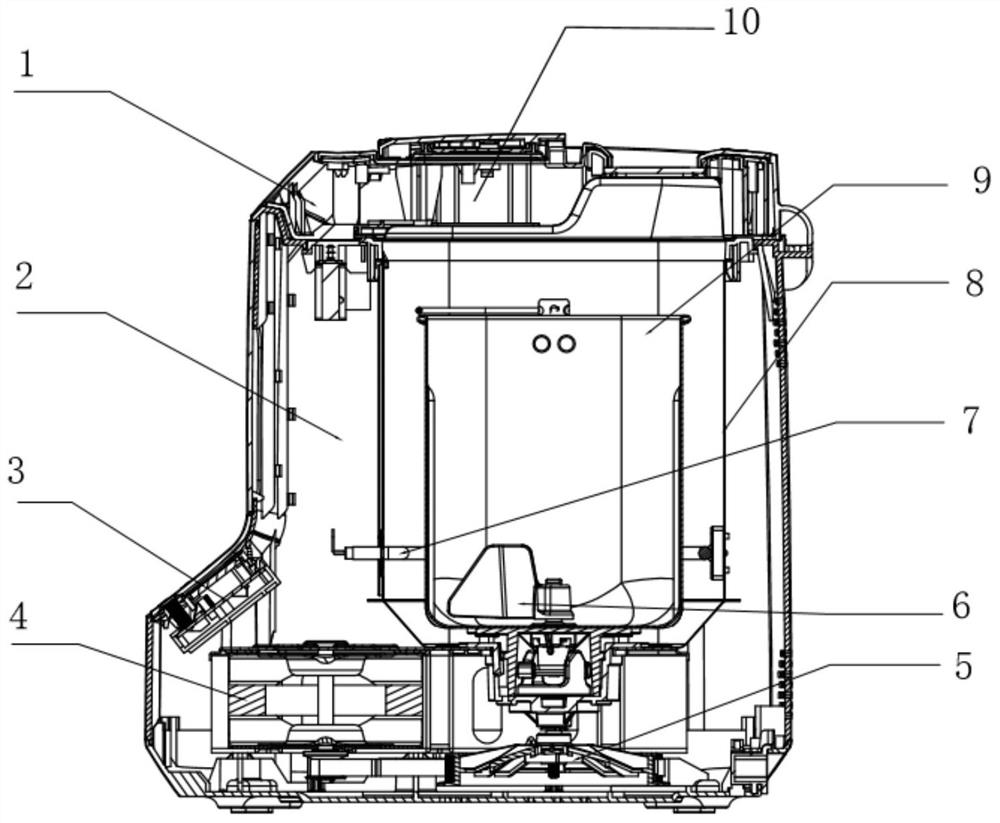

[0057] Embodiment 1 and Embodiment 8 are solutions within the scope of the technical solutions of the present invention. Follow the above steps, followed by: 1) Mixing stage S1, 2) Water absorption stage S2, 3) Kneading stage S3, 4) Refreshing stage, 5) Exhaust and oxygen absorption stage, 6) Fermentation stage S4 and 7) Baking stage S5.

[0058] The recipes used in Examples 1 to 8 are: 85g flour, 265g high-gluten flour, 35g butter, 42g sugar, 6g salt, 14g milk powder, 4g dry yeast, 70g dried fruit, and 157.5g water.

[0059] The time control conditions of each part of Embodiment 1 to Embodiment 8 are shown in Table 1. Embodiment 1 to embodiment 8 all add dried fruit when kneading dough and carry out to 60%.

[0060] Each part time control condition of table 1 embodiment 1-8

[0061]

[0062] The temperature control conditions of each part of Embodiment 1 to Embodiment 8 are shown in Table 2.

[0063] Each part temperature control condition of table 2 embodiment 1-8

...

Embodiment 1

[0067] The time and temperature control conditions of Comparative Example 1 are the same as in Example 1. Specifically include the following steps:

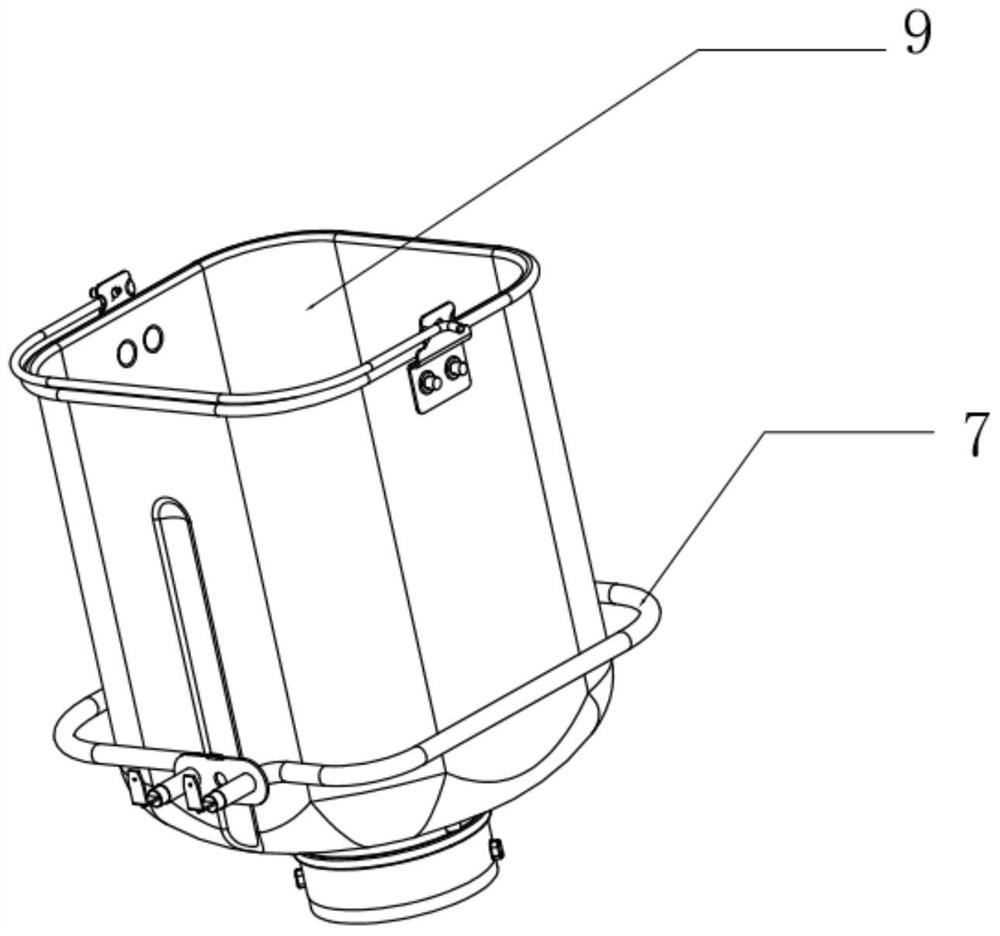

[0068] 1) Mixing stage S1: Put flour, high-gluten flour, butter, milk powder, salt, sugar and dry yeast in the bread bucket according to the ratio, and then add water; stir evenly, the stirring time is 15 minutes, and the heating element controls the stirring time The stirring temperature is 22°C;

[0069] 2) Water absorption stage S2: Stand still, let various components absorb water, the water absorption time is 30min, and the temperature of this water absorption stage is controlled at 22°C to obtain raw materials with sufficient water absorption;

[0070] 3) Kneading stage S3: After the water absorption is completed, enter the kneading link, and fully mix the materials with sufficient water absorption under the stirring action of the stirring mechanism of the bread machine to form a soft and elastic dough. The stirring time is...

Embodiment 2

[0076] The time and temperature control conditions of Comparative Example 2 are the same as in Example 2. Specifically include the following steps:

[0077] 1) Mixing stage S1: Put flour, high-gluten flour, butter, milk powder, salt, sugar and dry yeast in the bread bucket according to the ratio, and then add water; stir evenly, the stirring time is 10 minutes, and the heating element controls the stirring time The stirring temperature is 25°C;

[0078] 2) Water absorption stage S2: Stand still to allow various components to absorb water. The water absorption time is 20 minutes. The temperature in this water absorption stage is controlled at 25°C to obtain raw materials with sufficient water absorption;

[0079] 3) Kneading stage S3: After the water absorption is completed, enter the kneading link, and fully mix the materials with sufficient water absorption under the stirring action of the stirring mechanism of the bread machine to form a soft and elastic dough. The stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com