Device and method for real-time visualization of gear precision based on on-machine measurement of gear grinding machine

A technology for gear grinding machines and gears, which is applied in the direction of gear tooth manufacturing devices, gear cutting machines, and components with teeth, etc. It can solve the problems of wasting gear measurement and detection, limited measurement methods, and inability to equip on-machine measurement systems, etc., to achieve Avoid clamping errors and waste of time, automate and intelligentize the measurement process, and shorten the product processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0027]

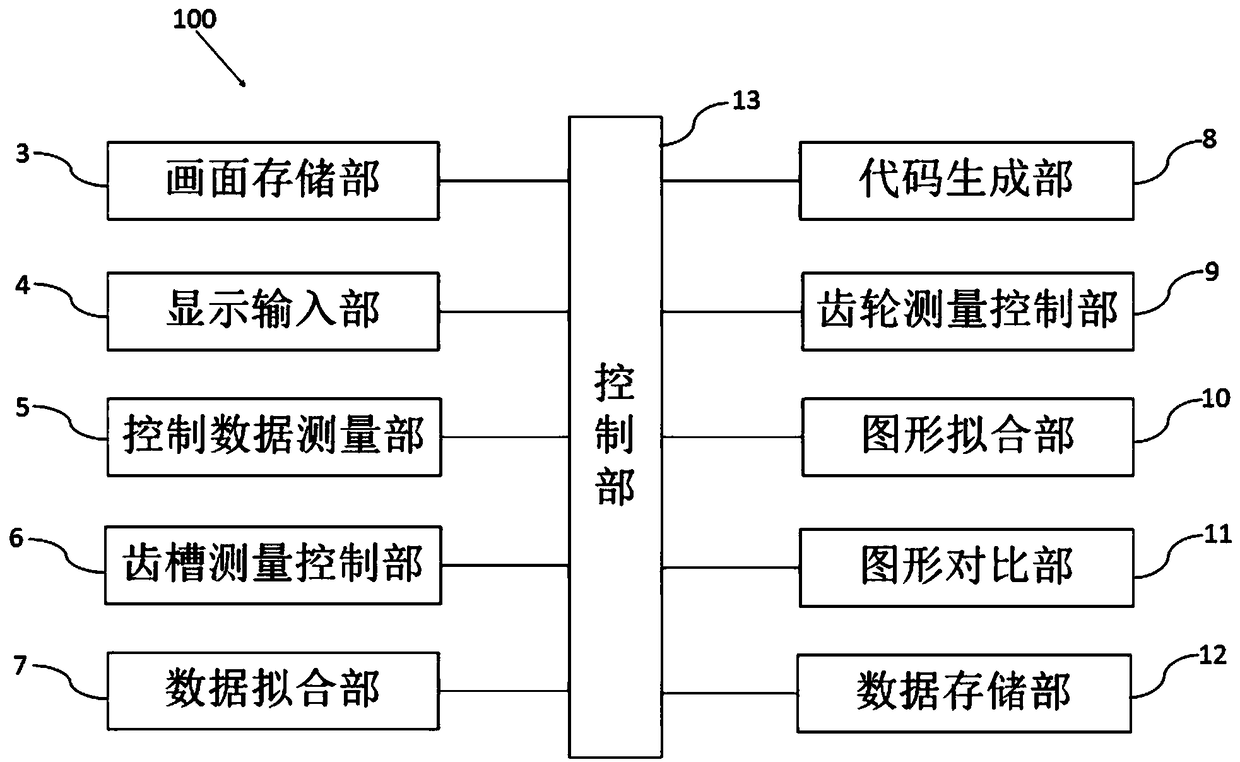

[0028] figure 1 It is a block diagram of the gear precision real-time visualization device based on the on-machine measurement of the gear grinding machine in the embodiment of the present invention.

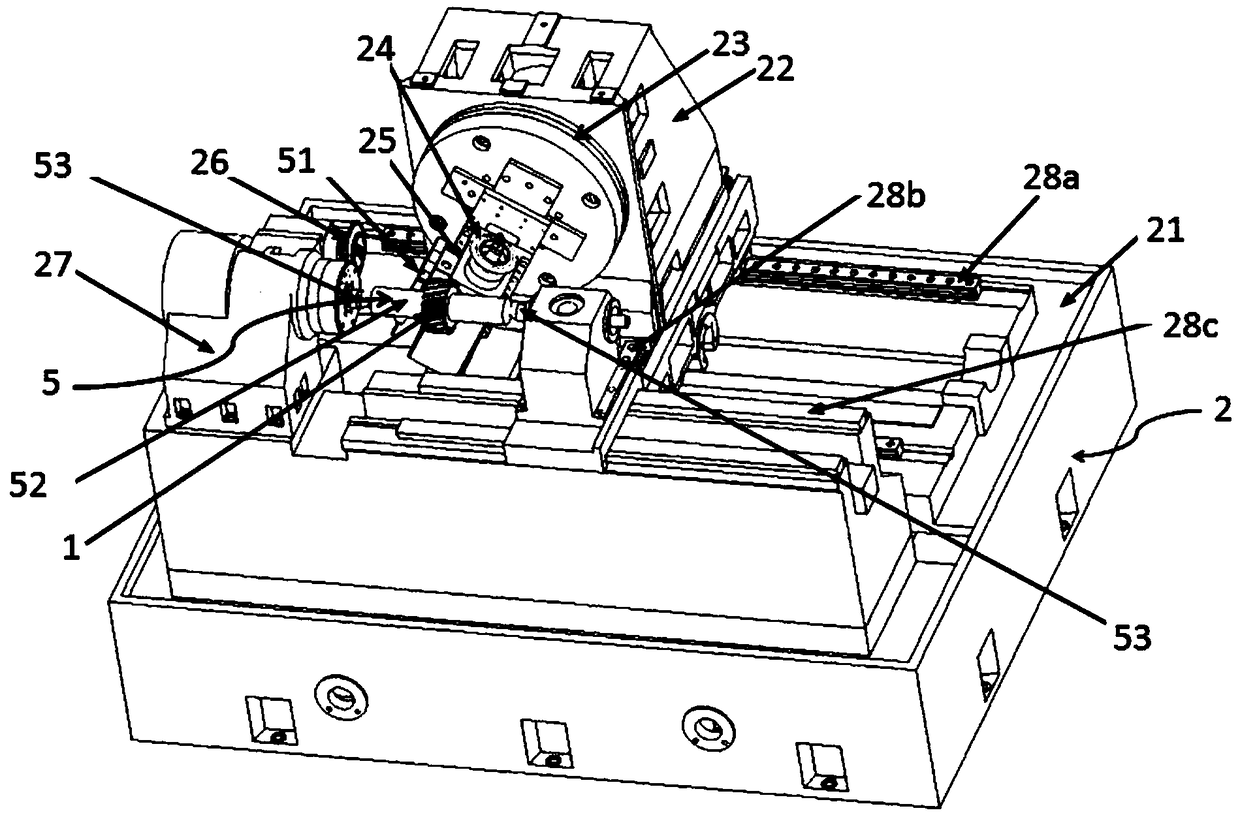

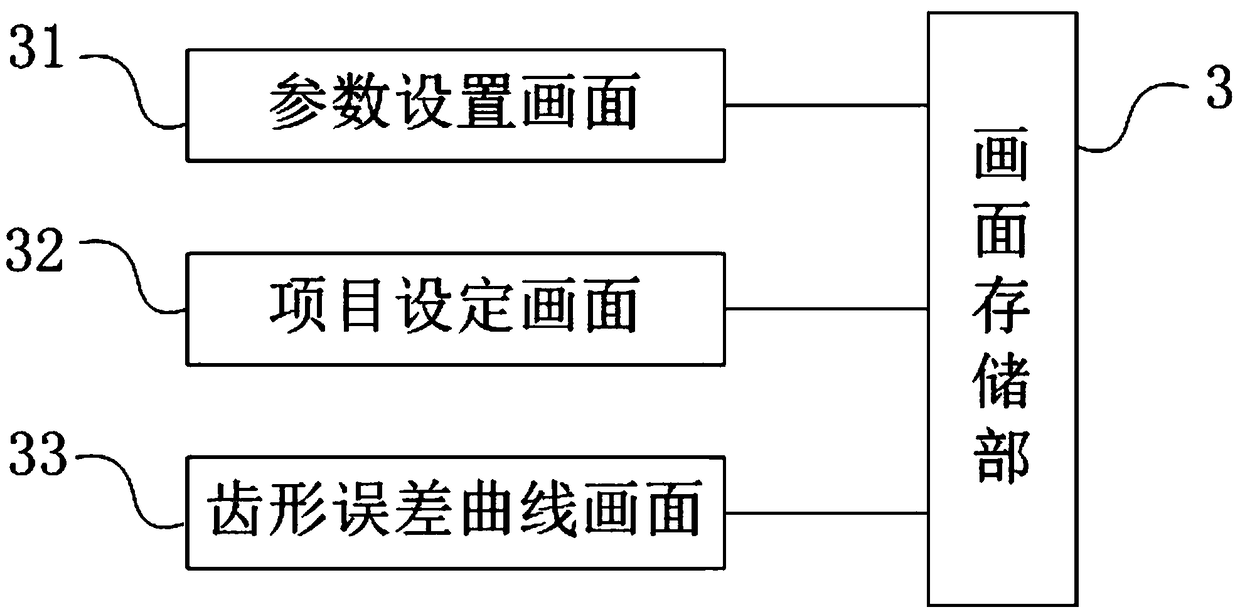

[0029] Such as figure 1 As shown, a gear precision real-time visualization device 100 based on the on-machine measurement of the gear grinding machine is set in the machine tool 2 for modifying the gear 1, and performs on-machine measurement on the modified gear 1, so that The operator obtains the surface topography state characteristics of the gear 1, including: screen storage part 3, display input part 4, control data measurement part 5, cogging measurement control part 6, data fitting part 7, code generation part 8, gear measurement The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com