Low-temperature preparation method of ZnB2O4 luminous material

A luminescent material, znb2o4 technology, applied in the field of low-temperature preparation of zinc borate ZnB2O4 luminescent material, can solve the problems of not maintaining product homogeneity and uniformity, particle agglomeration, energy consumption, etc. uniformity of diameter, reduction of calcination temperature, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of zinc borate ZnB 2 o 4 Low temperature preparation method of luminescent material

[0030] Proceed as follows:

[0031] 1) Weigh 3.8137g Na respectively 2 B 4 o 7 10H 2 O, 2.9751g Zn(NO 3 ) 2 ·6H 2 O.

[0032] 2) Add the weighed sample into a three-necked flask equipped with a condenser tube and a mechanical stirrer under stirring, and add 100 mL of distilled water to obtain a mixture.

[0033] 3) The mixture was placed in a water bath at 80° C. for 10 hours to obtain a white solid. The resulting white solid was repeatedly washed with distilled water and ethanol for 3-6 times, and then dried at 60° C. for 12 hours to obtain a precursor.

[0034] 4) The precursor is calcined at 500°C for 3 hours, the heating rate is 5°C per minute, and the target product can be obtained after cooling.

Embodiment 2

[0035] Embodiment 2 A kind of zinc borate ZnB 2 o 4 Low temperature preparation method of luminescent material

[0036] Only change the calcination temperature in step 4), that is, calcine the precursor at 600° C. for 3 hours; other steps are the same as in Example 1 to obtain the target product.

Embodiment 3

[0037] Embodiment 3 A kind of zinc borate ZnB 2 o 4 Low temperature preparation method of luminescent material

[0038] Only change the calcination temperature in step 4), that is, calcine the precursor at 700° C. for 3 hours; other steps are the same as in Example 1 to obtain the target product.

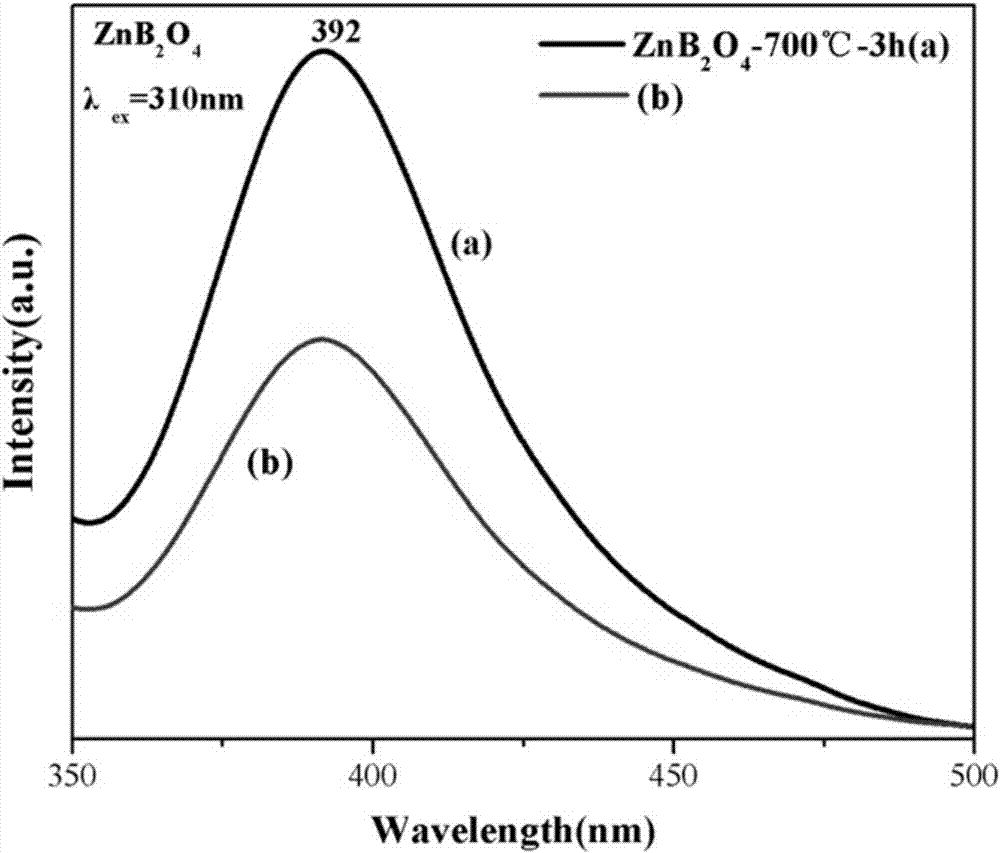

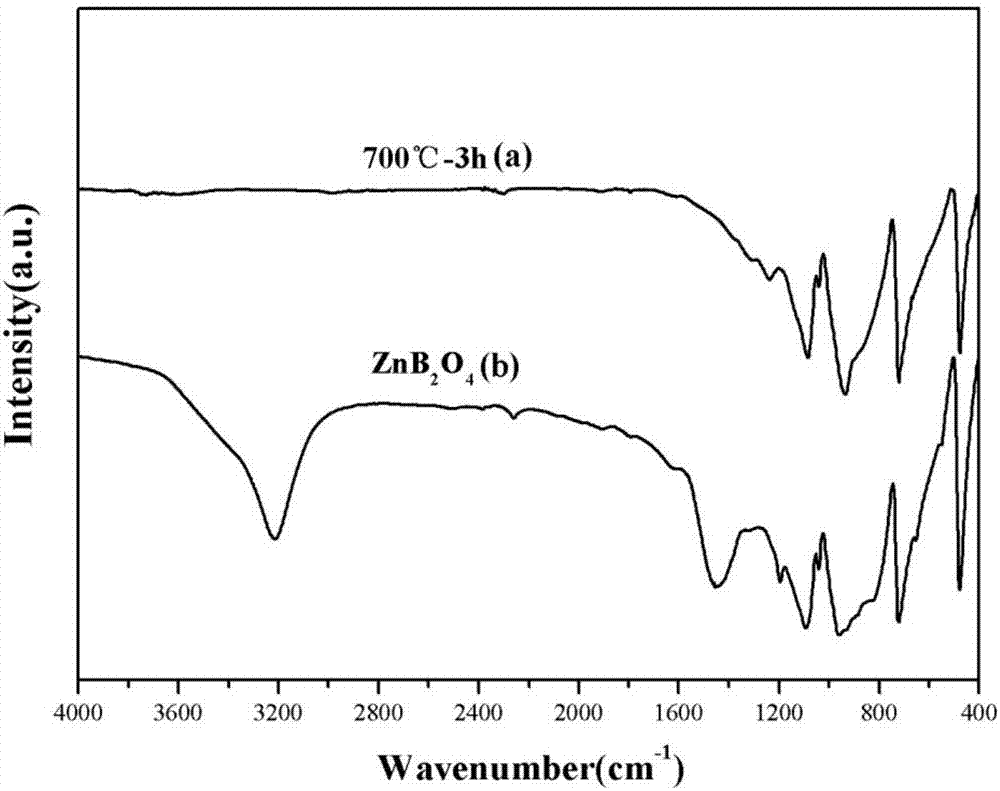

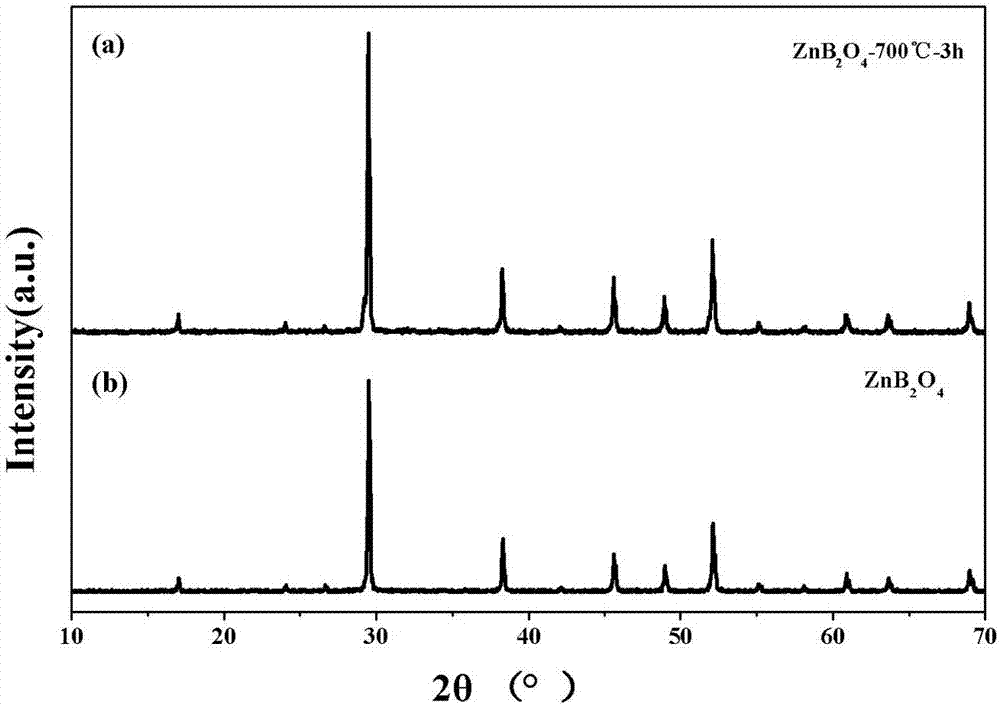

[0039] Effect of calcination temperature on zinc borate ZnB 2 o 4 Influence of luminescent material: It can be seen from Examples 1-3 that when the calcination temperature is 700°C, the obtained zinc borate ZnB 2 o 4 The particle size of the powder is relatively uniform and the purity is high. Therefore the preferred zinc borate ZnB 2 o 4 The optimum calcination temperature is 700°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com