Method and equipment for treating drilling fracturing return liquid of oil and gas field

A technology for fracturing flowback fluid and treatment methods, which is applied in sludge treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve problems such as difficult treatment, strong acidity, and strong corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

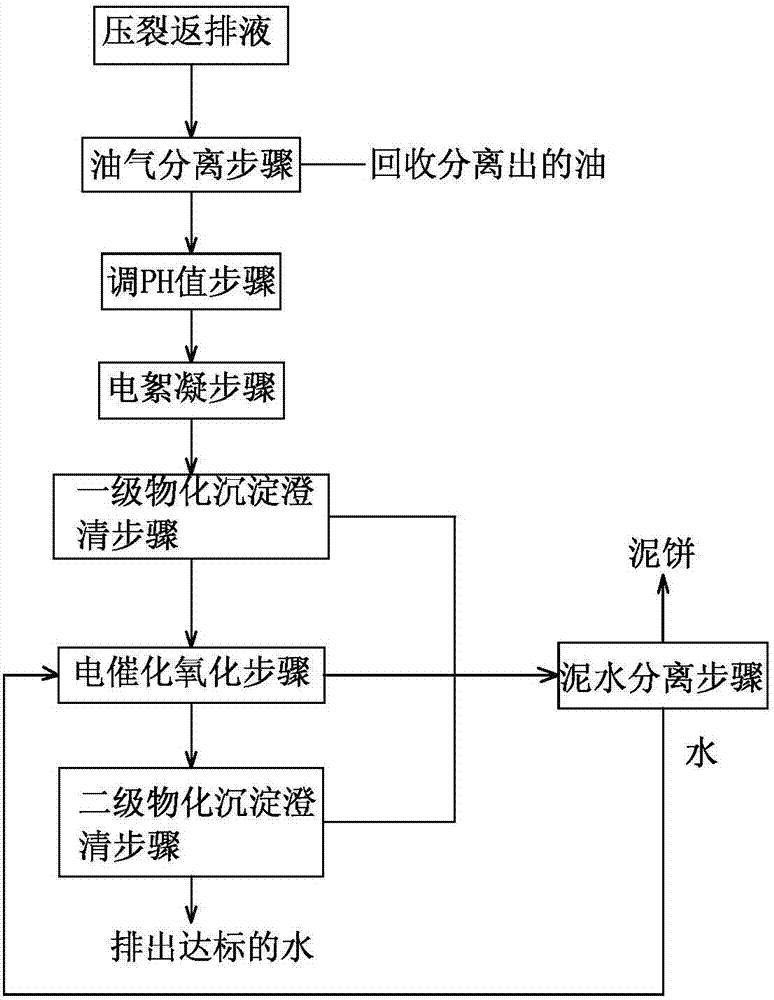

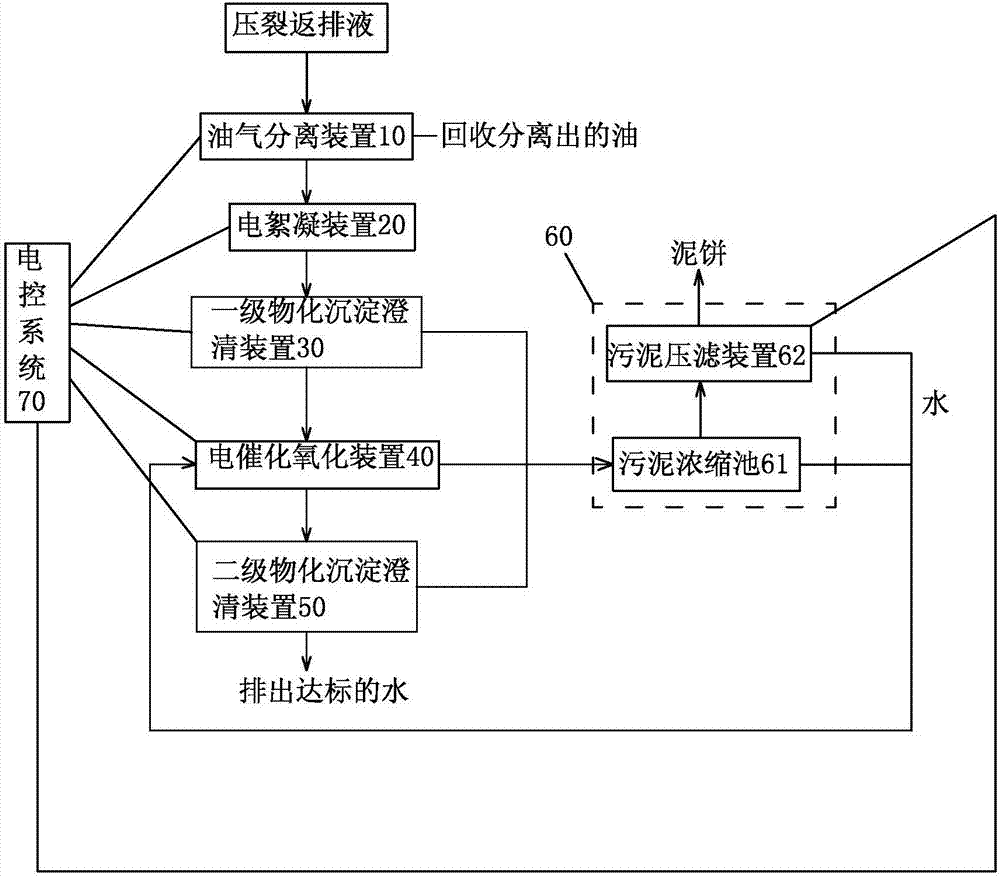

[0031] Please check figure 1 , oil and gas field drilling fracturing flowback fluid treatment method, including:

[0032] Step (1), the oil and gas separation step, separates the oil and water of the fracturing flowback fluid, and recovers the separated oil; in the specific steps: the fracturing flowback fluid is pumped into a separation container with a bubble generator through a sewage pump, and the fracturing The flowback liquid flows into the separation container, and the micro-bubbles generated by the electric floating device in the separation container float to the liquid surface with the fine oil strains mixed in the liquid, and the oil on the liquid surface is skimmed by the micro-bubbles into the upper opening of the separation container The fracturing flowback fluid from which the oil is separated is pumped to the next step for treatment;

[0033] Step (2), the step of adjusting the pH value, adjusts the pH value of the fracturing flowback fluid of the separated oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com