Method and equipment for treating oil-containing sludge cuttings of oil and gas field

A treatment method and technology of treatment equipment, applied in the direction of sludge treatment, electrochemical sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing treatment costs, pollution, and increasing the difficulty of resource utilization, etc. Achieve the effect of improving oil recovery rate, good separation effect and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

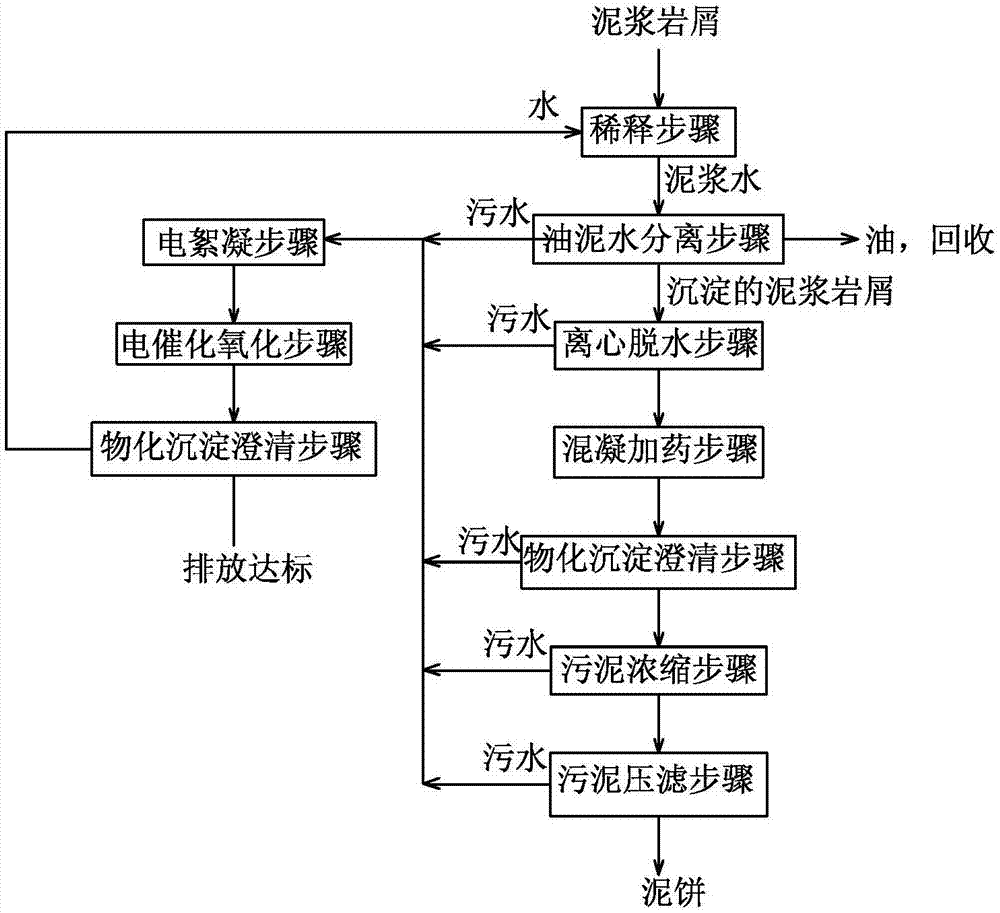

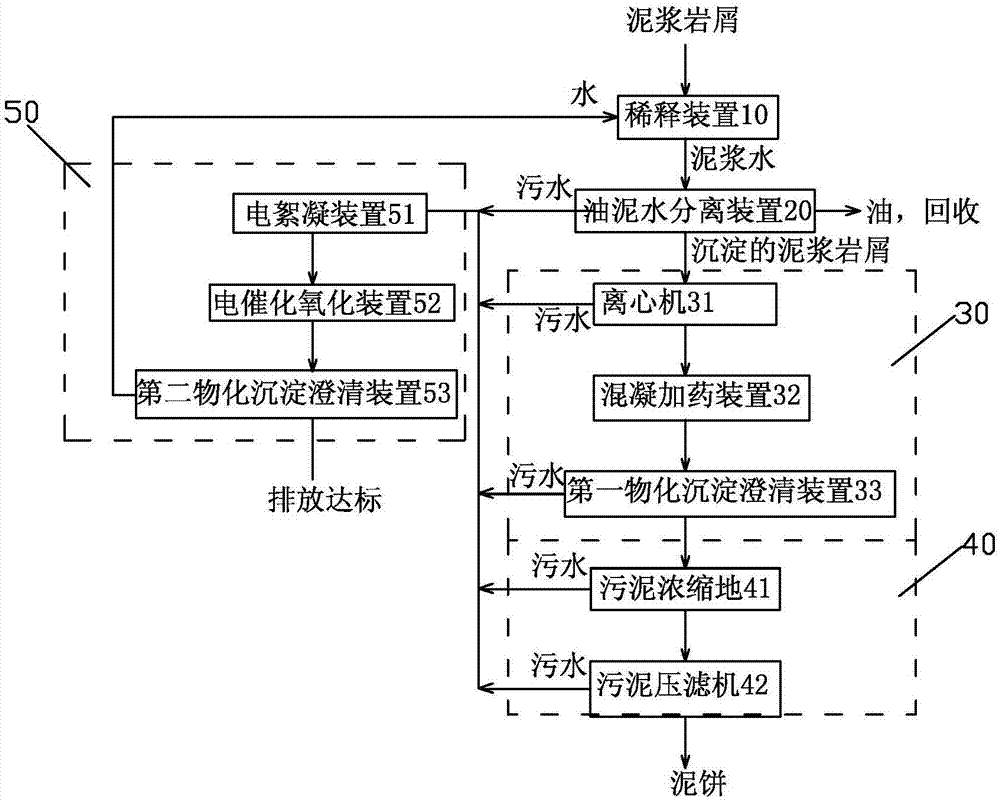

[0049] Please check figure 1 , a method for treating oily mud cuttings in oil and gas fields, including:

[0050] (1) In the dilution step, water is added to the oily mud cuttings to dilute the oily mud cuttings into mud water, and the mud water is stirred until it is fully stirred so that it can be evenly and smoothly transported to the next process. Among them: the dilution factor depends on the mud consistency and is generally 2 to 10 times, that is, the mass ratio is 2-10 times.

[0051] (2), oil sludge water separation step, separate oil from mud water, recover the separated oil, and obtain sedimented mud cuttings and sewage after separating oil and mud cuttings;

[0052] (3), dehydration step, carry out dehydration treatment to the mud rock debris that settles down, and the water that escapes is sewage;

[0053] (4), curing step, solidifying the dehydrated mud cuttings to be able to resource utilization;

[0054] (5) Sewage treatment step, treating the sewage in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com