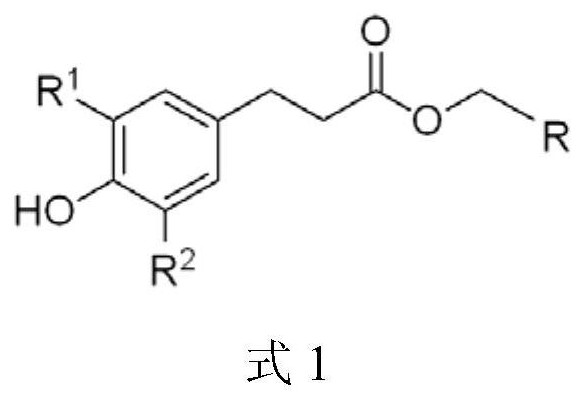

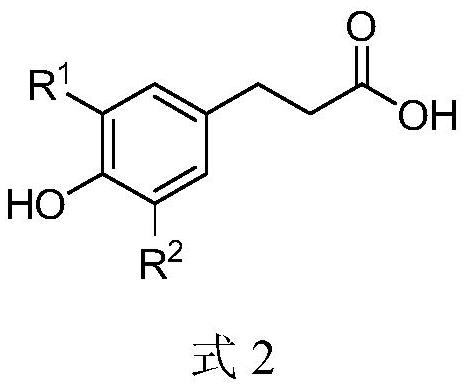

A kind of phenylpropionate derivative and its preparation method and application

A technology of phenylpropionate and derivatives, which is applied in the field of related medicines, can solve the problems of less attention on lipid-lowering effect, achieve the effects of improving lipid metabolism, optimizing synthesis route and process parameter conditions, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 2

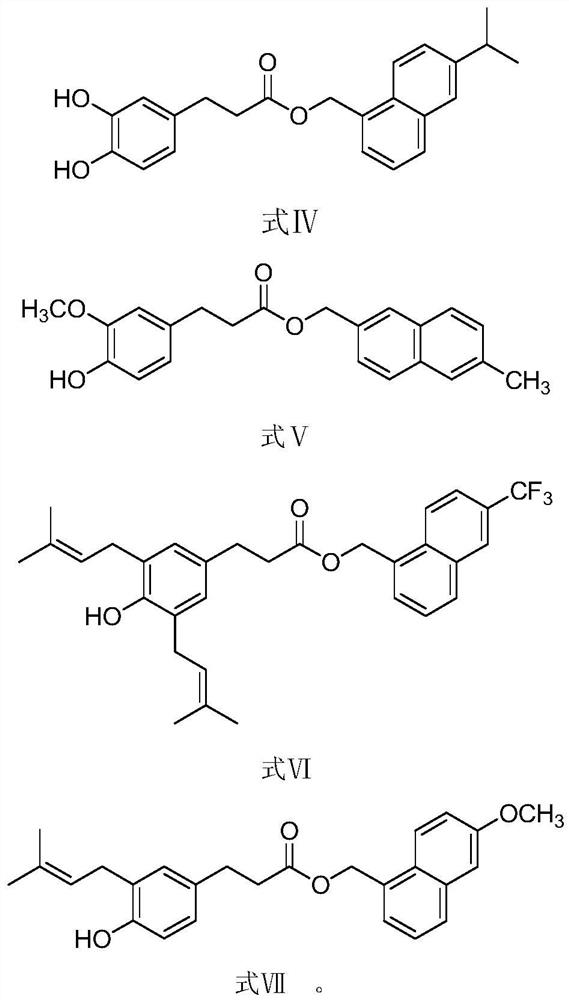

[0050] The synthesis of example 1 dihydrocaffeic acid-2-naphthyl methyl ester (PN1 for short, as shown in formula II)

[0051]

[0052] 1) Weigh 1.10mmol of dihydrocaffeic acid, dissolve in 1.5mL DMSO, add 1.32mmol of Na 2 CO 3 After stirring at room temperature for 0.5 h, 1.10 mmol of potassium iodide and 1.20 mmol of 2-(chloromethyl)naphthalene were added in sequence. The reaction mixture was stirred at 60 °C for 6 h (end of reaction by TLC).

[0053] 2) After the reaction was completed, cool to room temperature, add 5 mL of saturated sodium chloride solution and 5 mL of ethyl acetate, mix well and let stand to separate layers; the aqueous phase was extracted twice with ethyl acetate (3 mL×2 times), and the organic phase was combined, Then washed with saturated copper sulfate solution (3mL×4 times), and saturated sodium chloride solution (2mL×2 times), dried over anhydrous sodium sulfate, and then rotary evaporated (-0.08MPa, 45°C) to remove the solvent to obtain solid ...

example 2

[0055] The synthesis of example 2 p-hydroxyphenylpropionic acid-1-naphthylmethyl ester (PN for short, as shown in formula III)

[0056]

[0057] 1) Weigh 1.10mmol of p-hydroxyphenylpropionic acid, dissolve in 1.5mL of acetone, add 2.2mmol of NaHCO 3 After stirring at room temperature for 1 h, 2.2 mmol of lithium iodide and 2.2 mmol of 1-(bromomethyl)naphthalene were sequentially added. The reaction mixture was stirred at 40 °C for 12 h (end of reaction by TLC).

[0058] 2) Cool to room temperature after the reaction, add 10mL of saturated sodium chloride solution and 5mL of ethyl acetate, mix well and let stand to separate layers; extract the aqueous phase twice with ethyl acetate (3mL×2 times), combine the organic phases, Wash with saturated sodium chloride solution (2 mL×2 times), dry over anhydrous sodium sulfate, and then remove the solvent by rotary evaporation (-0.08 MPa, 45° C.) to obtain a solid crude product.

[0059] 3) The crude product is purified by column ch...

example 3 2

[0060] The synthesis of example 3 dihydrocaffeic acid-1-naphthalene-(5-isopropyl)-methyl ester (PN for short, as shown in formula IV)

[0061]

[0062] 1) Weigh 1.10mmol of dihydrocaffeic acid, dissolve in 1.5mL DMF, add 3.3mmol of KHCO 3 After stirring at room temperature for 1 h, 3.3 mmol of sodium iodide and 1.20 mmol of 1-(chloromethyl)-(5-isopropyl)-naphthalene were added sequentially. The reaction mixture was stirred at 80 °C for 3 h (end of reaction by TLC).

[0063] 2) After the reaction was completed, cool to room temperature, add 5 mL of saturated sodium chloride solution and 5 mL of ethyl acetate, mix well and let stand to separate layers; the aqueous phase was extracted twice with ethyl acetate (3 mL×2 times), and the organic phase was combined, Then washed with saturated copper sulfate solution (4mL×4 times), and saturated sodium chloride solution (2mL×2 times), dried over anhydrous sodium sulfate, and then rotary evaporated (-0.08MPa, 45°C) to remove the solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com