Superfine fiber polyurethane suede leather capable of removing formaldehyde and preparation method of superfine fiber polyurethane suede leather

A technology for removing formaldehyde and microfibers, applied in fiber processing, textiles and papermaking, etc., can solve problems affecting users' health, etc., and achieve the effect of improving fastness, good formaldehyde removal effect, and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

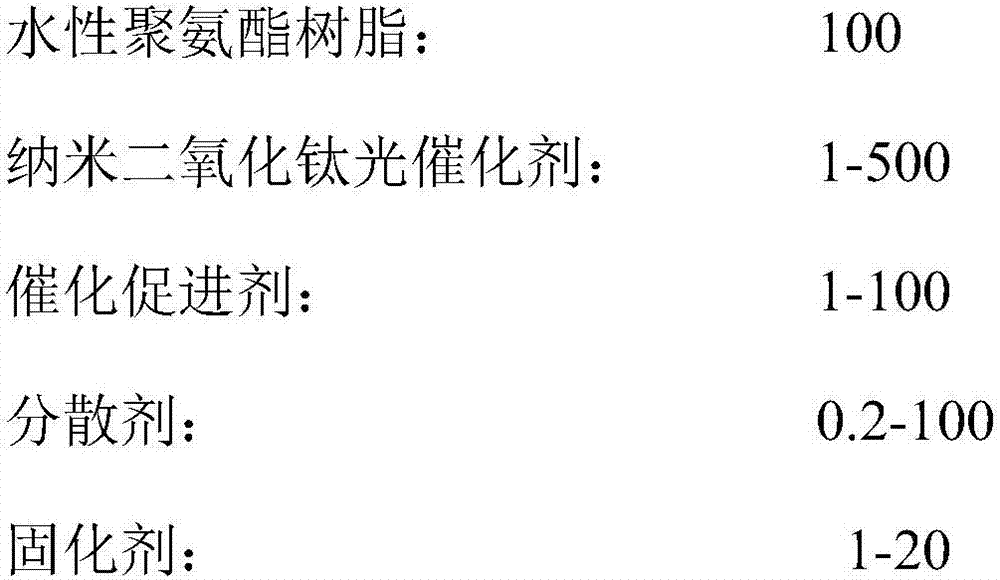

[0031] (1) raw materials (mass parts):

[0032]

[0033] Preparation method: Mix the components, then stir for 60 minutes under the condition of 1000 rpm, and then grind once on a three-roll mill to obtain a formaldehyde-removing agent.

[0034] (2) After drying the microfiber suede at a temperature of 80° C. for 30 minutes, immerse it in the above-mentioned formaldehyde-removing treatment agent for 100 seconds, and the bath ratio is 1:1;

[0035] Then dry at a temperature of 80° C. for 30 minutes to obtain the polyurethane microfiber suede that can remove formaldehyde;

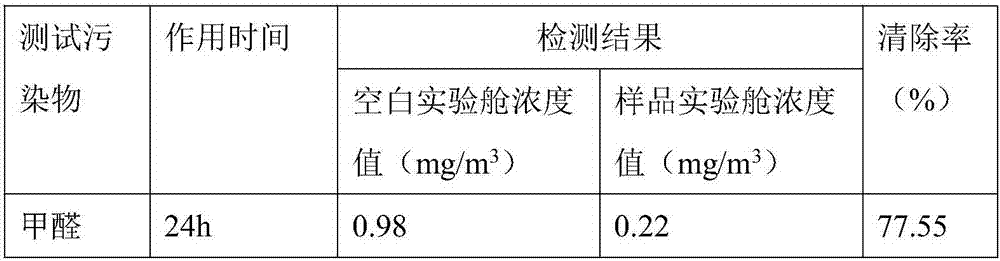

[0036] Adopt QB / T2761-2006 method to test the effect of above-mentioned invention to remove formaldehyde as follows:

[0037]

Embodiment 2

[0039] (1) raw materials (mass parts):

[0040]

[0041]

[0042] Preparation method: Mix the components, then stir for 10 minutes under the condition of 5000 rpm, and then grind once on a three-roll mill to obtain a formaldehyde-removing agent.

[0043] (2) After drying the microfiber suede leather at a temperature of 160° C. for 5 minutes, immerse it in the above-mentioned formaldehyde-removing treatment agent for 500 seconds, and the bath ratio is 1:20;

[0044] Then dry at a temperature of 160° C. for 5 minutes to obtain the polyurethane microfiber suede that can remove formaldehyde;

[0045] Adopt QB / T2761-2006 method to test the effect of above-mentioned invention to remove formaldehyde as follows:

[0046]

Embodiment 3

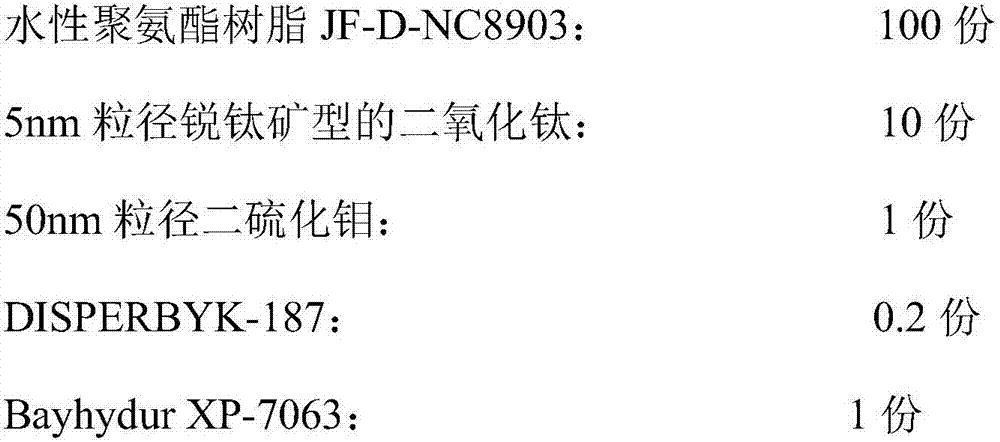

[0048] (1) raw materials (mass parts):

[0049]

[0050] Preparation method: Mix the various components, then stir for 20 minutes under the condition of 2500 rpm, and then grind once on a three-roll mill to obtain a formaldehyde-removing treatment agent.

[0051] (2) After drying the microfiber suede leather at a temperature of 130° C. for 10 minutes, immerse it in the above-mentioned formaldehyde-removing treatment agent for 300 seconds, and the bath ratio is 1:10;

[0052] Then dry at a temperature of 140° C. for 15 minutes to obtain the polyurethane microfiber suede that can remove formaldehyde;

[0053] Adopt QB / T2761-2006 method to test the effect of above-mentioned invention to remove formaldehyde as follows:

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com