Safe and environment-friendly flare system based on fire whirlwind vortex generating mechanism

A safety and environmental protection, torch system technology, applied in the direction of combustion type, combustion method, incinerator, etc., can solve the problems of poor combustion stability, low combustion efficiency, and low service life of the torch head, and achieve reduced service life, stable combustion flame, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

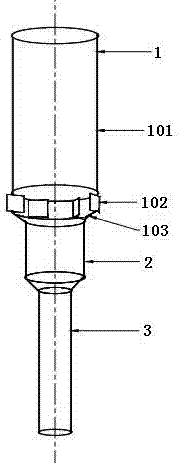

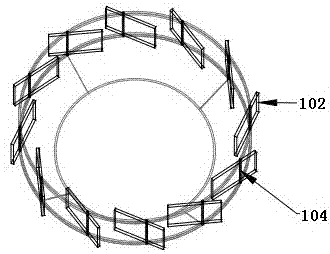

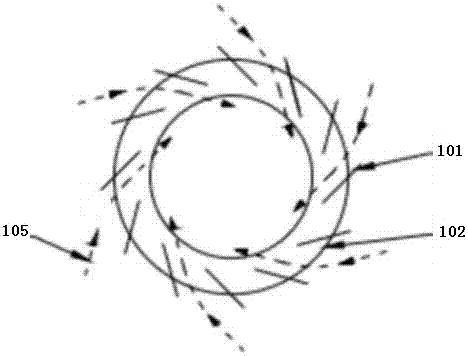

[0026] Example: such as figure 1 with figure 2 As shown, a safe and environment-friendly torch system based on the generation mechanism of the fire whirlwind vortex includes a fire whirlwind vortex generation device 1, a flare head 2 and a flare barrel 3, and the fire whirlwind vortex generation device 1 is arranged on a fixed device 103 The upper part of the torch head 2, the fire whirlwind vortex generating device 1 is made up of a hollow cylinder 101 and several deflectors 102, the deflectors 102 are arranged between the hollow cylinder 101 and the fixing device 103, and the fixing device 103 extends upwards There are several support rods 104, the bottom of the support rods 104 is connected with the fixing device 103, the top of the support rods 104 is connected with the hollow cylinder 101, the deflector 102 is arranged on the support rods 104, and one support rod 104 is provided with a The deflector 102, wherein the height of the hollow cylinder 101 is 120 meters, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com