Nondestructive testing system for defects of composite insulator based on reflecting property of microwave band

A composite insulator, microwave band technology, applied in the field of composite insulator defect non-destructive testing systems, can solve problems such as misjudgment, inability to read phase, waveform distortion, inability to identify and detect transient information, to avoid detection failure, integration high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

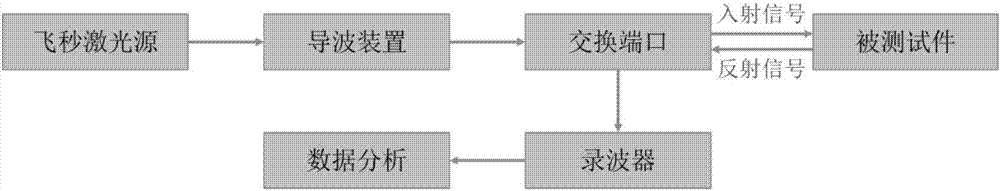

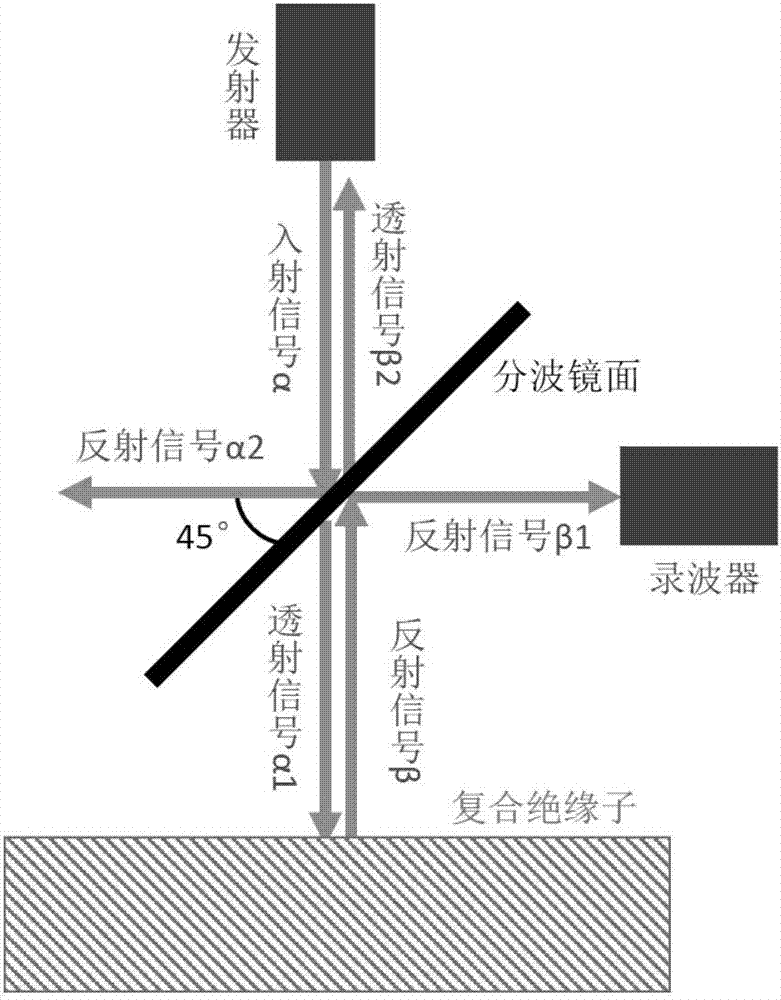

[0060] combine figure 1 , figure 2 , a non-destructive detection system for composite insulator defects based on microwave band reflection characteristics, including a femtosecond laser source, a waveguide device, an exchange port, a wave recorder and a data analysis module;

[0061] The femtosecond laser source is a generator of the detection signal required by the detection method, and the width of the generated laser pulse signal is at the femtosecond level, and has good penetration and reflection characteristics.

[0062] The guided wave device is a physical structure connecting the femtosecond laser source and the switching port, which is designed to ensure that the original pulse signal can be transmitted to the transmitting end without damage.

[0063] The switch port is a component mainly composed of a mirror surface with bidirectional permeability to microwave band signals with silica glass material as the main component.

[0064] The incident signal α transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com