65MW large power klystron

A klystron, high-power technology, applied in the field of ultra-high frequency vacuum electronic devices, can solve the problems of poor performance of microwave output ceramic windows, low welding yield of microwave output windows, etc., to avoid ignition in the tube, improve stability, The effect of improving the pressure resistance of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

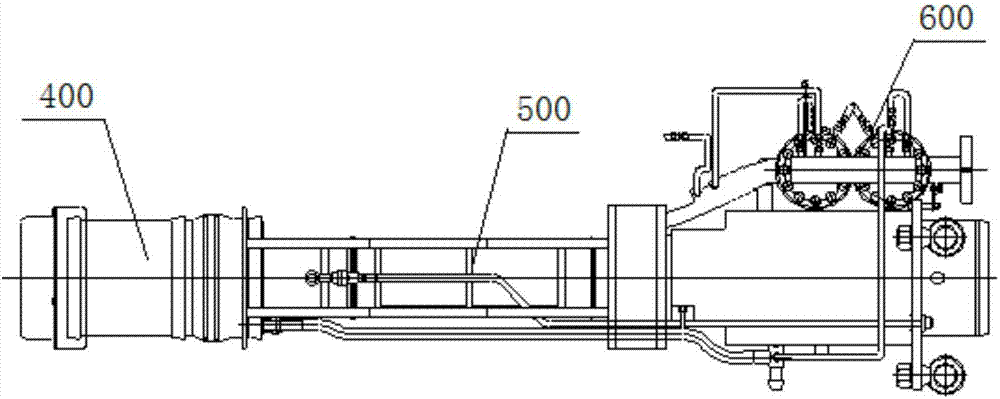

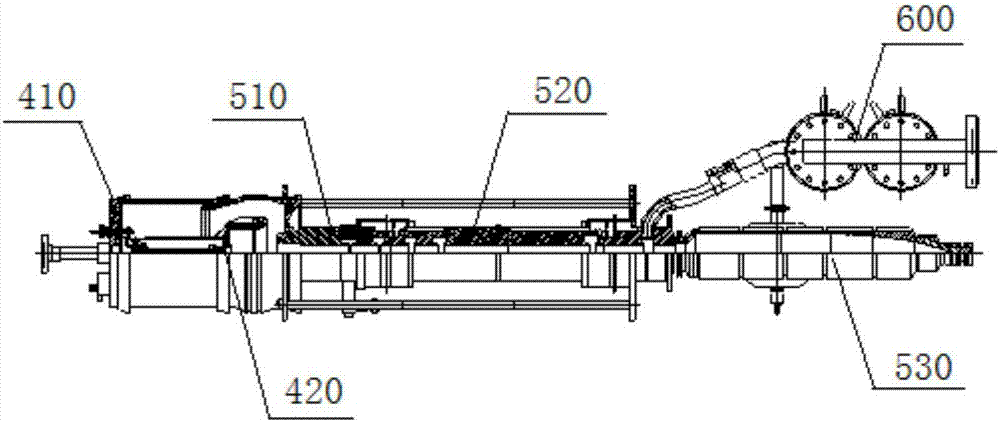

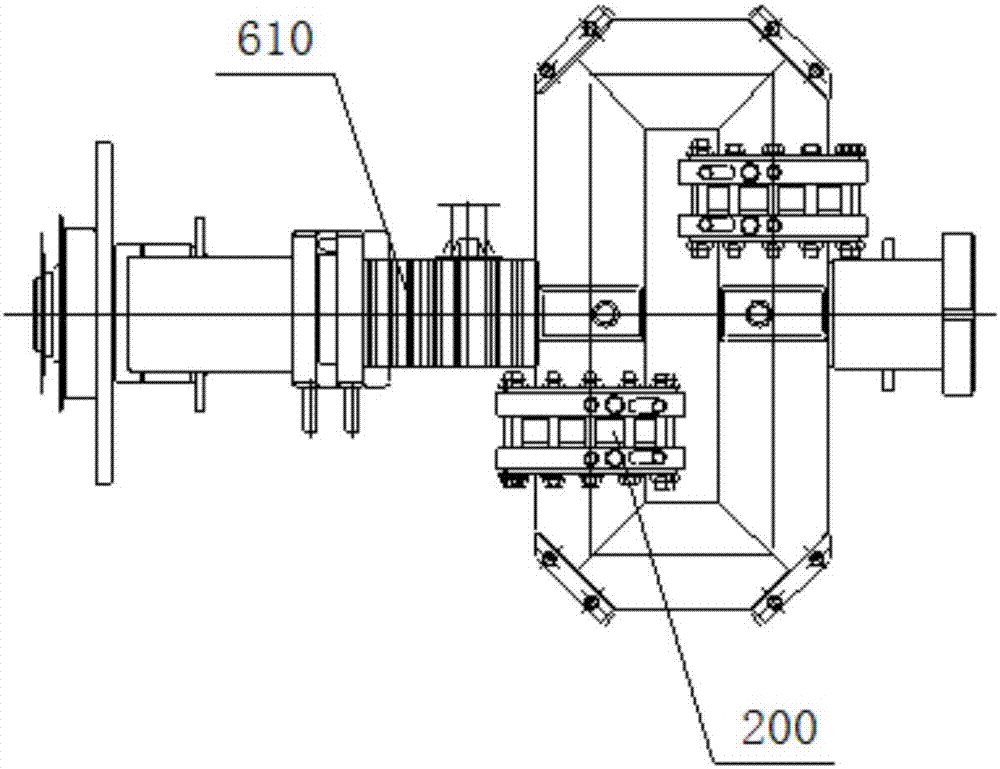

[0060] Such as figure 1 , figure 2 The 65MW high-power klystron shown includes an electron gun assembly 400, a cluster section assembly 500, an output section assembly 600, and a collector 530; the electron gun assembly 400 includes an insulating ceramic assembly 410, and an electron gun core 420 built in the insulating ceramic assembly 410; The cluster section assembly 500 includes an input cavity and a two-cavity assembly 510, a long drift tube high-frequency gain section 520; image 3 As shown, the output section assembly 600 includes a dual-window output section composite waveguide 610 and a microwave output window 200 arranged on the dual-window output section composite waveguide 610; Figure 4 As shown, the electron gun core 420 includes a focusing pole support 430, a cathode support 440, a focusing pole 450 installed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com