Passenger car series-parallel hybrid transmission

A transmission and hybrid technology, applied in power plants, hybrid vehicles, pneumatic power plants, etc., can solve problems such as low efficiency and achieve high transmission efficiency, easy cost control, and flexible layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

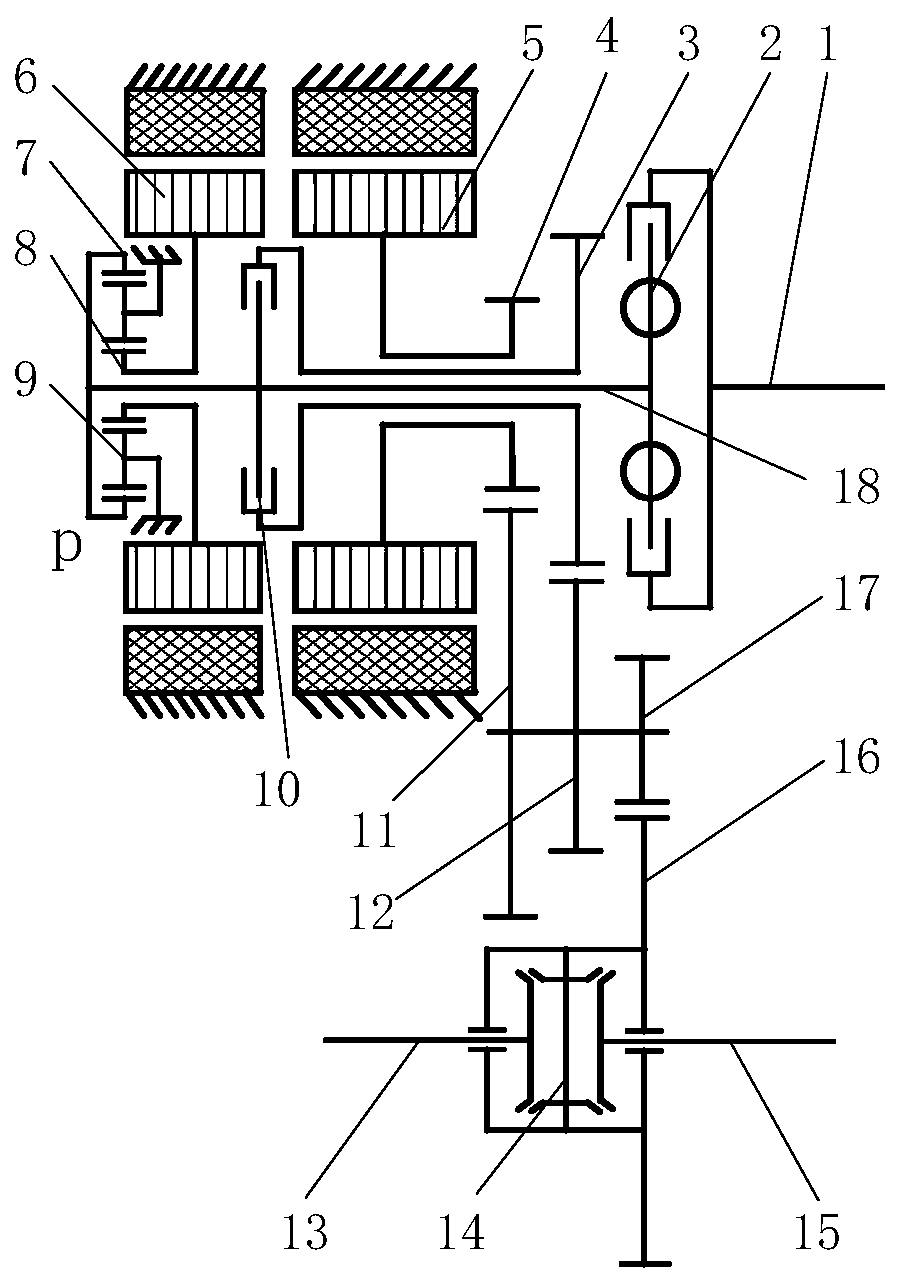

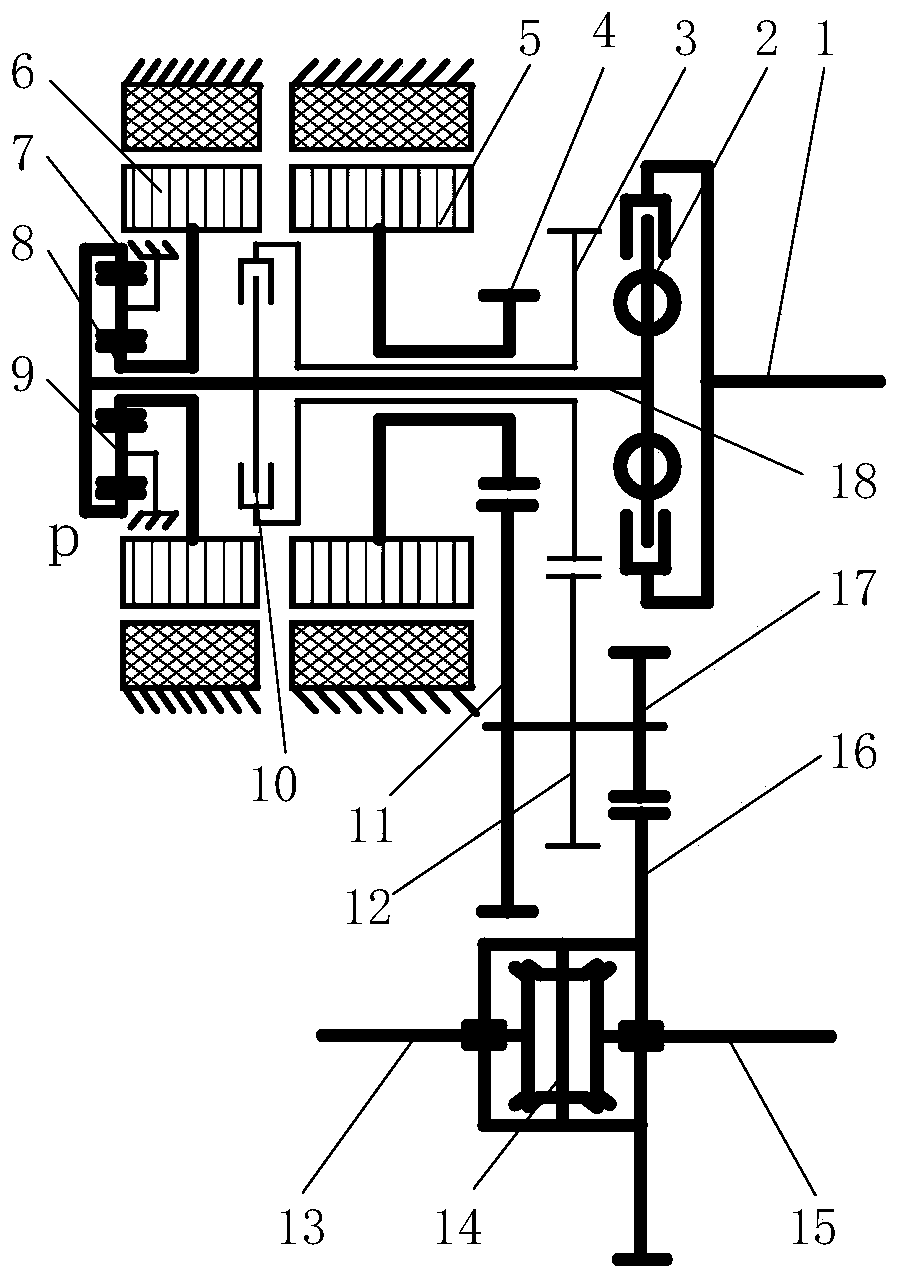

[0028] This embodiment provides a series-parallel hybrid power transmission device suitable for passenger vehicles, such as figure 1 As shown, the transmission device includes: an input shaft 18, a shock absorber 2, a clutch 10, a speed-increasing planetary row, a differential 14, an electric motor 5, a generator 6 and a plurality of gears. Wherein, the electric motor 5 and the generator 6 are coaxially arranged, the speed-increasing planetary row is arranged on the side where the generator 6 is located, and the clutch 10 is located between the motor 5 and the generator 6, and the connection relationship is: one end of the input shaft 18 passes through the shock absorber 2 Connect the engine input shaft 1, and the other end is sequentially connected with the driving end of the clutch 10 and the ring gear 7 of the speed-up planetary row, the planet carrier 9 of the speed-up planetary row brakes, the rotor of the generator 6 and the sun Round 8 connections.

[0029] The rotor o...

Embodiment 2

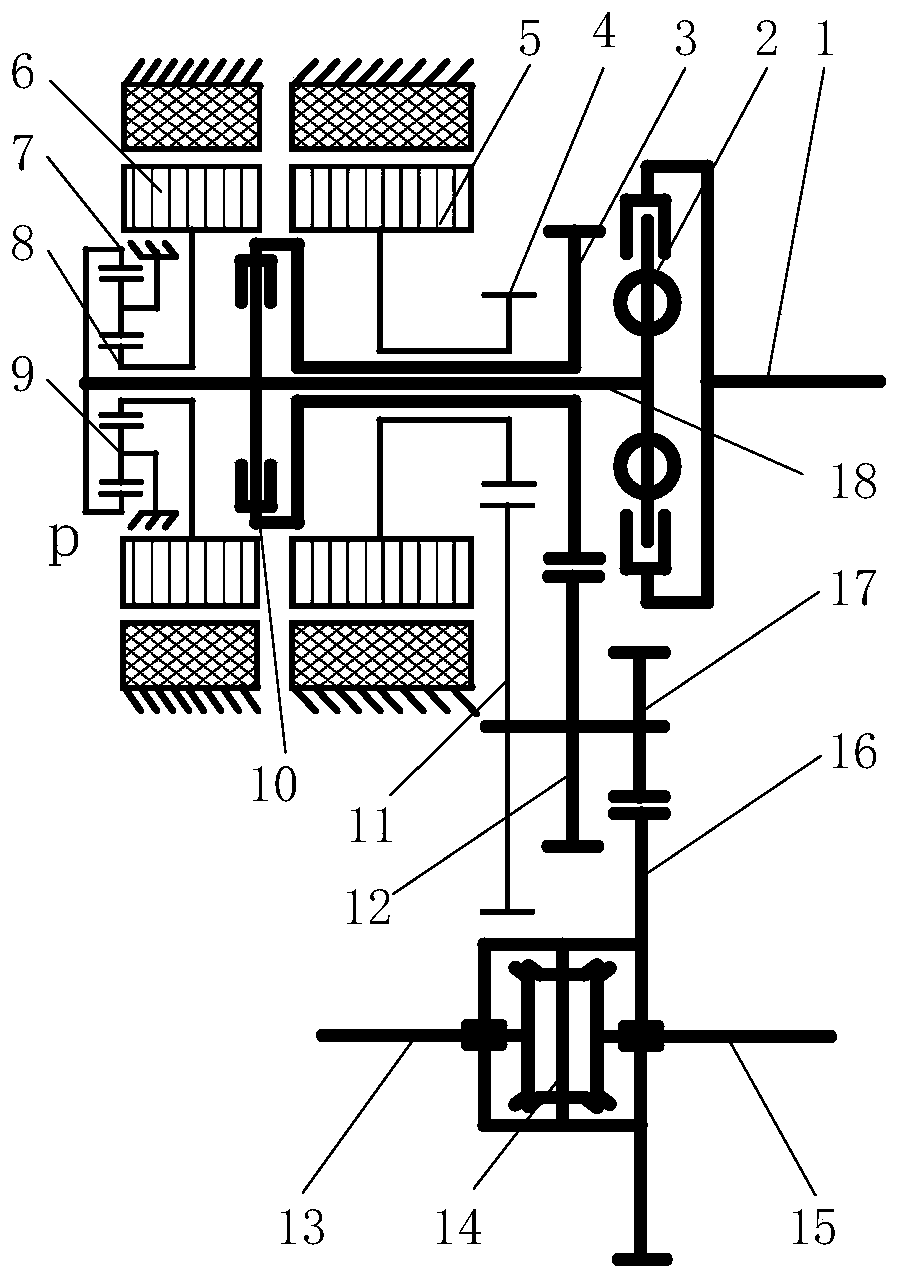

[0033] like Figure 4 shown, with figure 1 The difference of Embodiment 1 shown is that the clutch 10 is arranged at the input end, its driving end is connected with the input shaft 18 , and its driven end is connected with the gear A3. The arrangement of the clutch 10 at the input end can simplify the number of sleeve shaft layers, that is, only the gear shaft of the gear B4 is coaxially sleeved outside the input shaft 18, but the axial length will be increased.

[0034] In the above two embodiments, the generator and the motor are coaxially arranged, and the speed-increasing planetary row is arranged on the side of the generator, so as to increase the speed of the generator and increase the power density of the generator. The power of the electric motor is transmitted to the differential through two pairs of fixed shaft gears to drive the wheels on both sides. After the clutch is engaged, the power of the engine is transmitted to the differential through another pair of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com