Composite temporary plugging agent for refracturing of horizontal well and temporary plugging method

A technology of repeated fracturing and temporary plugging agent, which is applied in chemical instruments and methods, drilling composition, earth-moving drilling, etc. Problems such as horizontal well construction and inability to soften and bond, to achieve the effect of improving the success rate of repeated fracturing, good plugging effect, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

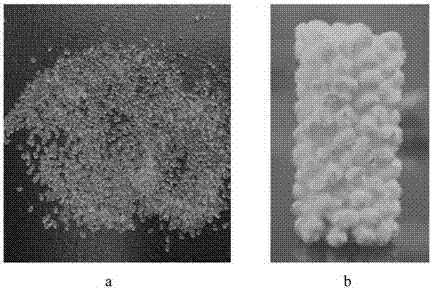

[0043] Take soluble polybutylene succinate (Anqing Hexing Chemical Co., Ltd.) as component A, pulverize it, and sieve out 4-8 mesh particles. After component A is soaked in tap water at 90°C for 10 hours, the bonding effect occurs, and the shape is as follows: figure 1 .

[0044] Partially hydrolyzed polyacrylamide (Beijing Xitao Technology Development Co., Ltd.) was used as component B, and granules of 10-20 mesh were sieved by crushing.

[0045] Put component A and component B into tap water respectively, within 8 minutes component A hardly swells, while component B swells about 3.2 times.

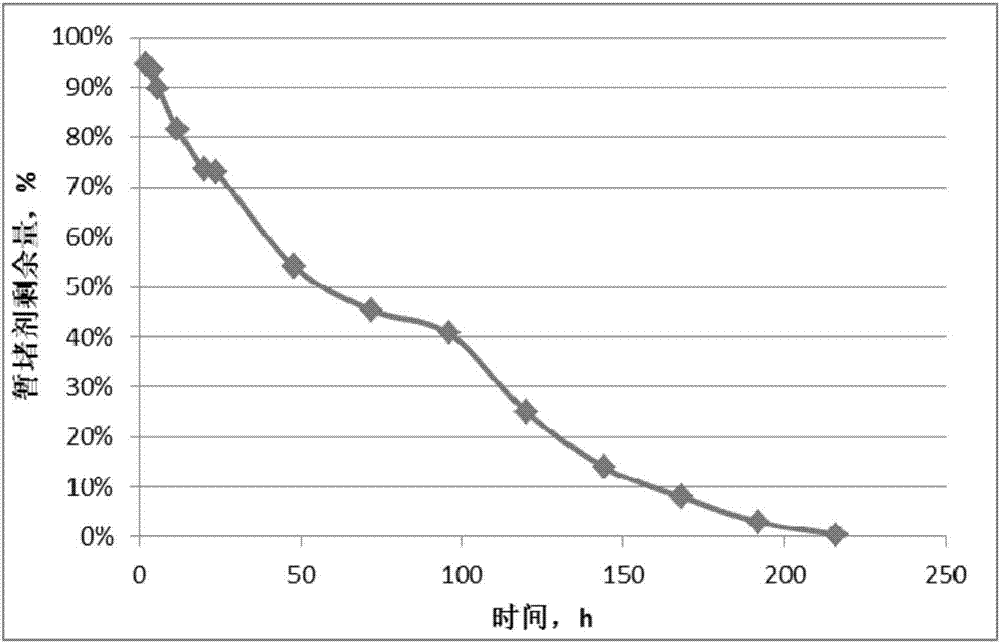

[0046] Mix component A and component B at a weight ratio of 4:1 to form a composite temporary plugging agent a. Put the composite temporary plugging agent a into tap water at 90°C. After 200 hours, the dissolution rate will reach more than 96%. The degradation curve is shown in figure 2 . The water-insoluble content of composite temporary plugging agent a was determined to be 4.5wt%...

Embodiment 2

[0056] Take soluble polyglycolic acid (Shenzhen Boli Biomaterials Co., Ltd.) as component A, pulverize it, and sieve out 4-8 mesh particles. After component A is soaked in tap water at 90°C for 10 hours, the bonding effect occurs.

[0057] The partially hydrolyzed copolymer of 2-acrylamide-2-methylpropanesulfonic acid and acrylamide (Beijing Xitao Technology Development Co., Ltd.) is used as component B, and the particles of 10-20 meshes are screened out by crushing. Put component A and component B into tap water respectively, within 10 minutes component A hardly swells, while component B swells about 4.2 times.

[0058] Mix component A and component B at a weight ratio of 5:1 to form a composite temporary plugging agent d. The composite temporary plugging agent d is put into tap water at 100°C, and after 200 hours, the dissolution rate reaches over 96%. The water-insoluble content of composite temporary plugging agent d was determined to be 4.5wt% after 240 hours at 90°C. ...

Embodiment 3

[0061] Soluble polyethylene lactide (Shenzhen Boli Biomaterials Co., Ltd.) was used as component A, which was pulverized and sieved to obtain 4-8 mesh particles. After component A is soaked in tap water at 90°C for 10 hours, the bonding effect occurs.

[0062] The copolymer of partially hydrolyzed acrylic acid and acrylamide (Shandong Taihe Water Treatment Technology Co., Ltd.) was used as component B, and granules of 10-20 mesh were screened out by crushing. Put component A and component B into tap water respectively, within 8 minutes component A hardly swells, while component B swells about 3.6 times.

[0063] Mix component A and component B at a weight ratio of 6:1 to form a composite temporary plugging agent e. The composite temporary plugging agent e is put into tap water at 90°C, and after 200 hours, the dissolution rate reaches over 96%. The water-insoluble content of composite temporary plugging agent e was determined to be 4.5wt% after 240 hours at 90°C.

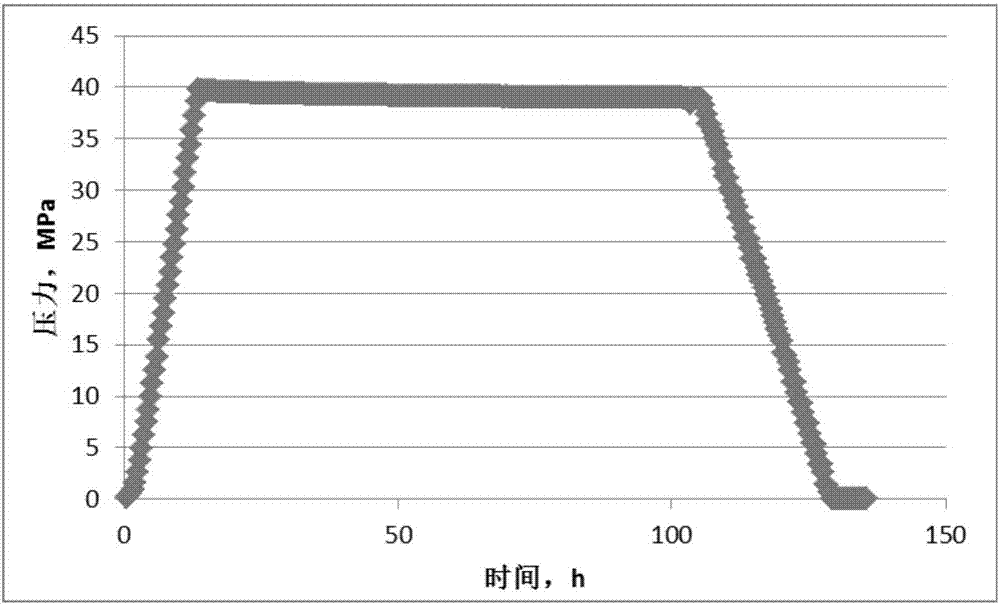

[0064] Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com