Construction technology of cement mixing pile in soft soil roadbed

A technology of cement mixing piles and construction technology, which is applied in basic structure engineering, sheet pile wall, soil protection, etc. The effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

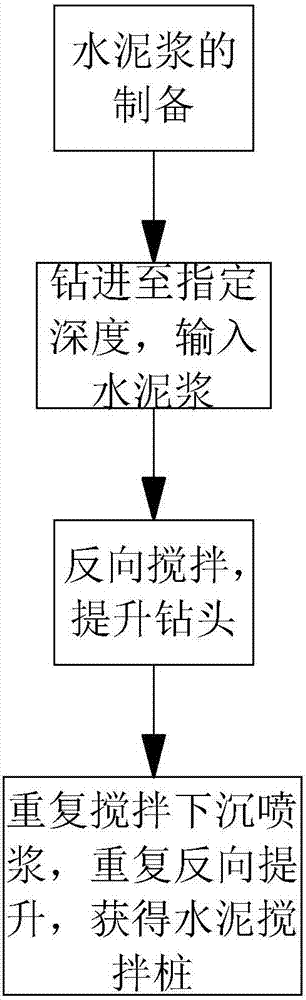

[0029] A construction process of cement mixing piles for soft soil roadbeds, including the following steps;

[0030] a1. The configuration of cement slurry: mix 10 parts of cement, 1 part of water reducing agent, 0.03 part of retarder, 1 part of air-entraining agent and 0.1 part of waterproofing agent, and add 5.5 parts of water, stir again to make cement slurry ;

[0031] a2. Use a mixing pile machine to drill the selected subgrade ground with a drilling speed of 0.8m / min and a drilling depth of 20m;

[0032] a3. After reaching the required depth, carry out reverse rotation lifting, while using compressed air to squeeze the cement slurry into the borehole;

[0033] a4. Through the mixing action of the drill bit, the cement can fully mix the cement slurry and the soil. While lifting the drill bit, spraying the liquefied material, stirring and mixing, the lifting speed is 0.8m / min, and at the same time, it should be Stay at the bottom of the pile for 30s, grind the end of the pile, li...

Embodiment 2

[0038] A construction process of cement mixing piles for soft soil roadbeds, including the following steps;

[0039] a1. The configuration of cement slurry: mix 20 parts of cement, 1.5 parts of water reducing agent, 0.06 parts of retarder, 2 parts of air-entraining agent and 0.4 parts of waterproofing agent, and add 12 parts of water, stir again to make cement slurry ;

[0040] a2. Use a mixing pile machine to drill the selected subgrade ground with a drilling speed of 0.8m / min and a drilling depth of 20m;

[0041] a3. After reaching the required depth, carry out reverse rotation lifting, while using compressed air to squeeze the cement slurry into the borehole;

[0042] a4. Through the mixing action of the drill bit, the cement can fully mix the cement slurry and the soil. While lifting the drill bit, spraying the liquefied material, stirring and mixing, the lifting speed is 0.8m / min, and at the same time, it should be Stay at the bottom of the pile for 30s, grind the end of the pil...

Embodiment 3

[0047] A construction process of cement mixing piles for soft soil roadbeds, including the following steps;

[0048] a1. The configuration of cement slurry: mix 15 parts of cement, 1.3 parts of water reducing agent, 0.04 parts of retarder, 1.5 parts of air-entraining agent and 0.3 parts of waterproofing agent, and add 8.5 parts of water, stir again to make cement slurry ;

[0049] a2. Use a mixing pile machine to drill the selected subgrade ground with a drilling speed of 0.8m / min and a drilling depth of 20m;

[0050] a3. After reaching the required depth, carry out reverse rotation lifting, while using compressed air to squeeze the cement slurry into the borehole;

[0051] a4. Through the mixing action of the drill bit, the cement can fully mix the cement slurry and the soil. While lifting the drill bit, spraying the liquefied material, stirring and mixing, the lifting speed is 0.8m / min, and at the same time, it should be Stay at the bottom of the pile for 30s, grind the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com