Stamping detonation combustion engine with free piston

A combustion engine and piston technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of large exhaust emissions and low combustion efficiency, and achieve the effects of less harmful gases, high thermal cycle efficiency, and rapid combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

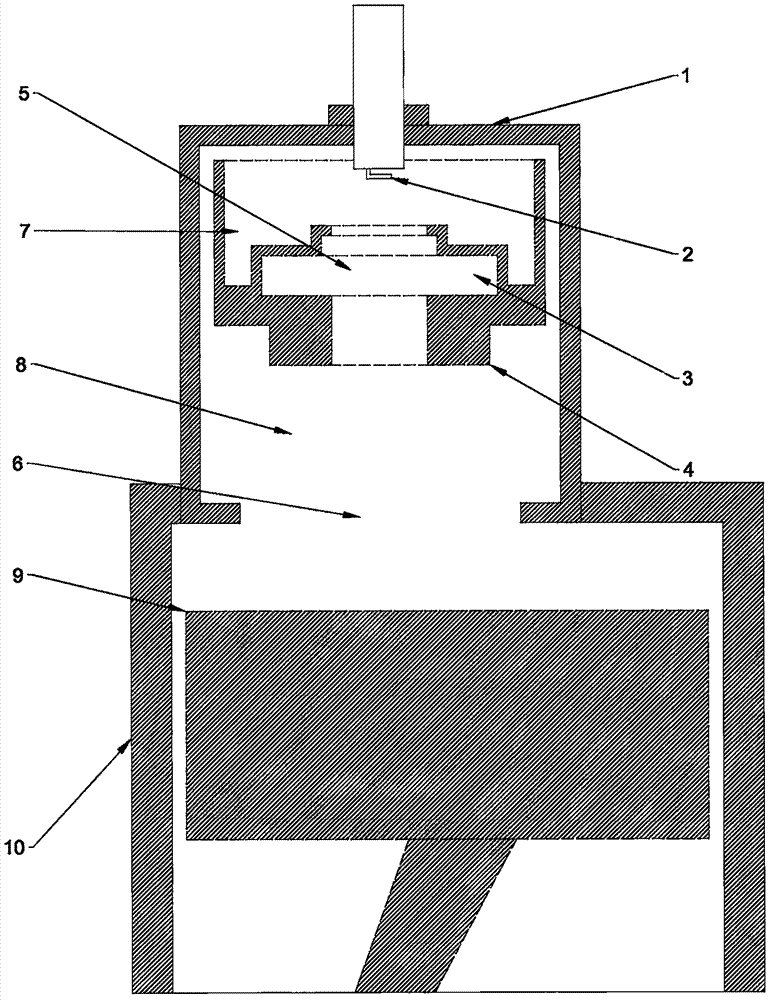

[0011] figure 1 Shown: A free piston 4 with a hole is installed in the small cylinder combustion chamber 1 of the engine, so that the small cylinder combustion chamber 1 constitutes a front combustion chamber 7 and a rear combustion chamber 8, on the top of the small cylinder combustion chamber 1. There is a spark plug 2 for an ignition device, the free piston 4 has a suitable central small vent 5 and a punched combustion chamber 3, the vent 6 communicates with the engine block 10, and the engine piston 9 matches the engine block 10.

[0012] When the engine of the present invention is in compression and working state: the engine piston 9 moves upward, and the gas first pushes the free piston 4 to the top of the small cylinder combustion chamber 1, and then continues to compress the gas to the set compression ratio; when the engine crankshaft causes the engine piston 9 When the angle is set after running to the top dead center, the spark plug 2 ignites to ignite the gas in the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com