Prefabricated directly-buried thermal insulation pipeline leakage detection system and method

A thermal insulation pipeline and leak detection technology, applied in the pipeline system, by detecting the appearance of fluid at the leak point, measuring devices, etc., can solve the problems of complex construction, high construction cost, waste of resources, etc., and achieve reduced construction complexity and strong Anti-jamming ability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

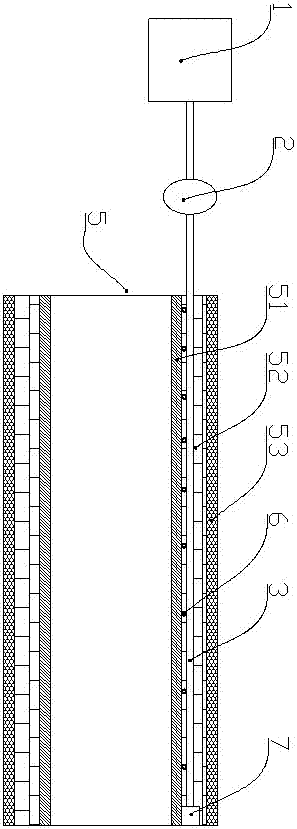

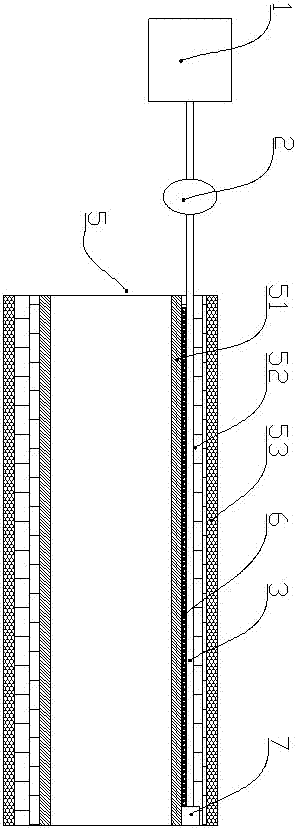

[0029] Such as figure 1 and figure 2 A prefabricated direct-buried thermal insulation pipeline leakage detection system is shown, comprising an optical time domain reflectometer 1, a coupling splitter 2, an optical fiber 3 and a thermal insulation pipeline 5, and the thermal insulation pipeline 5 includes a working tube 51, a polyurethane foam insulation layer 52 and Outer sheath layer 53; the optical fiber 3 is laid along the working tube 51, and a number of water-absorbing rubber particles 6 are distributed between the optical fiber 3 and the working tube 51, so that when the working tube 51 leaks, the water-absorbing rubber particles 6 absorb water and expand, which in turn causes macro bending of the optical fiber 3; the end of the optical fiber 3 is connected with a pigtail 7, and the pigtail 7 is laid on the end of the working tube 51, thereby ensuring that the optical time domain reflectometer 1 emits light The information is reflected by the optical time domain refle...

Embodiment 2

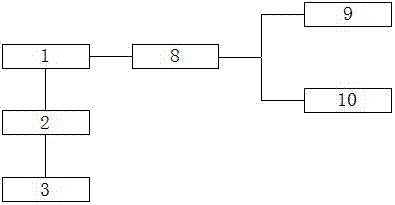

[0042] Such as figure 1 and image 3A prefabricated directly buried thermal insulation pipeline leakage detection system is shown, including optical time domain reflectometer 1, coupling splitter 2, optical fiber 3 and thermal insulation pipeline 5, and the coupling splitter 2 realizes multiple optical fibers 3 and optical time domain reflection The connection of the instrument 1, the heat preservation pipeline 5 includes a working pipe 51, a polyurethane foam insulation layer 52 and an outer sheath layer 53; the optical fiber 3 is laid along the working pipe 51 and distributed between the optical fiber 3 and the working pipe 51 There are several water-absorbing swelling glue particles 6, the water-absorbing swelling glue particles 6 are cylindrical particles with a diameter of not less than 1 cm, the diameter direction of the cylindrical particles intersects with the laying direction of the optical fiber 3 in a cross shape, and the cylindrical particles are tightly packed Di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap