Capacitive micromechanical band-pass filter with double elliptical plates

A band-pass filter and double ellipse technology, applied in electrical components, impedance networks, etc., can solve problems such as small motion impedance, increased process complexity, low frequency stability and repeatability, and achieve short response time and excellent mechanical Effects of electrical performance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

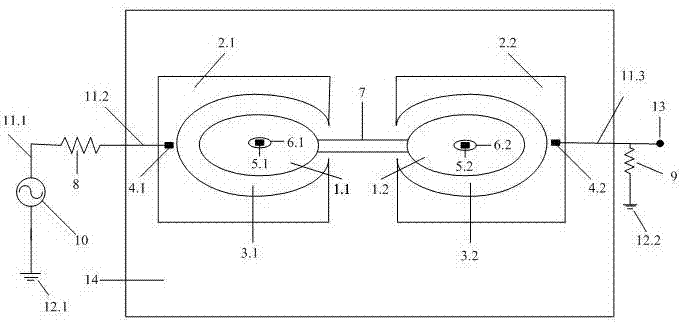

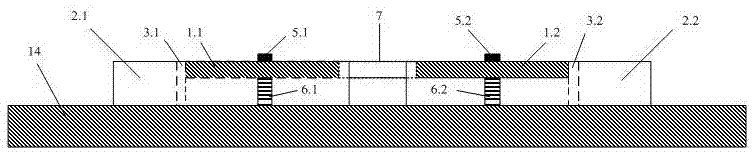

[0017] exist figure 1 Among them, the vibrating elliptical disks 1.1 and 1.2 are suspended on the substrate 14, and the anchor points 6.1 and 6.2 of the elliptical disks at the center of the bottom surface are supported to isolate them from the substrate 14. The vibrating elliptical disk 1.1 is surrounded by the input electrode 2.1, and the elliptical disk 1.2 is surrounded by the output electrode 2.2. 3.1 is the interval between the input electrode and the elliptical disk, and 3.2 is the interval between the output electrode and the elliptical disk. A coupling beam 7 connects the oval disks 1.1 and 1.2. The AC voltage solder joint 4.1 is introduced above the input electrode 2.1, one end of the AC voltage signal 10 is grounded 12.1, the other end is connected to the input resistor 8 through a metal wire 11.1, and the other end of the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com