Novel automatic turnover device for cylindrical lithium battery

A lithium battery, automatic technology, used in battery assembly, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve problems such as high scrap rate, short circuit of battery cells, and wrinkled skin, and achieve lightening workload and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

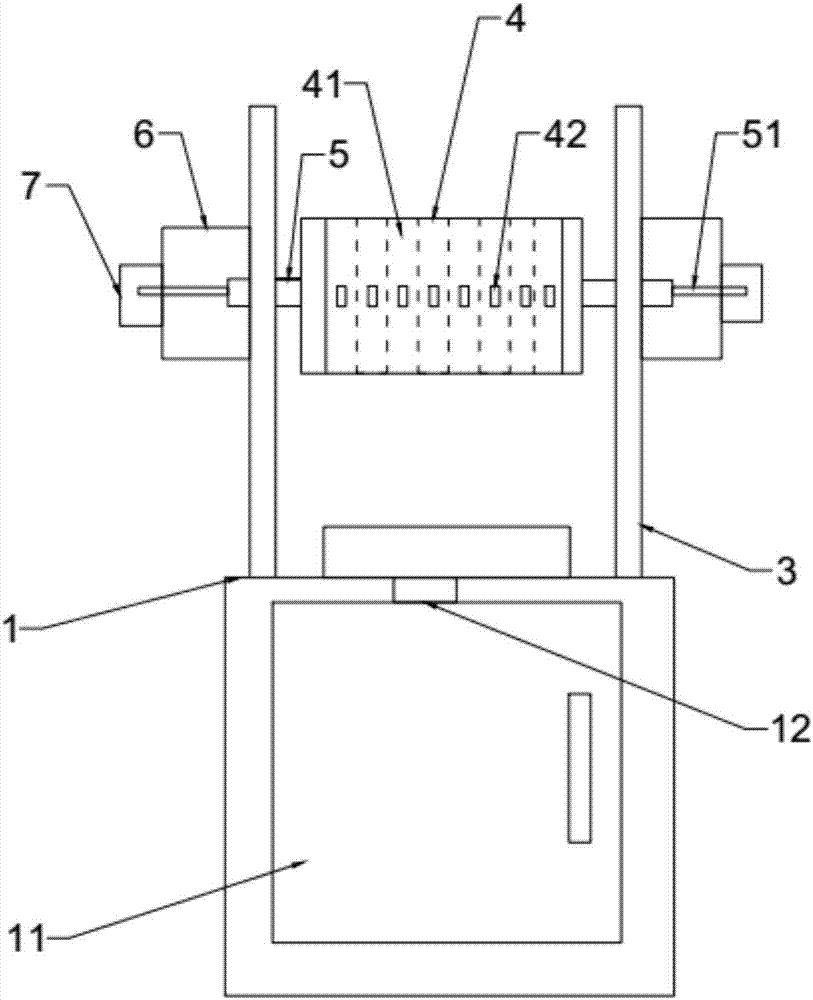

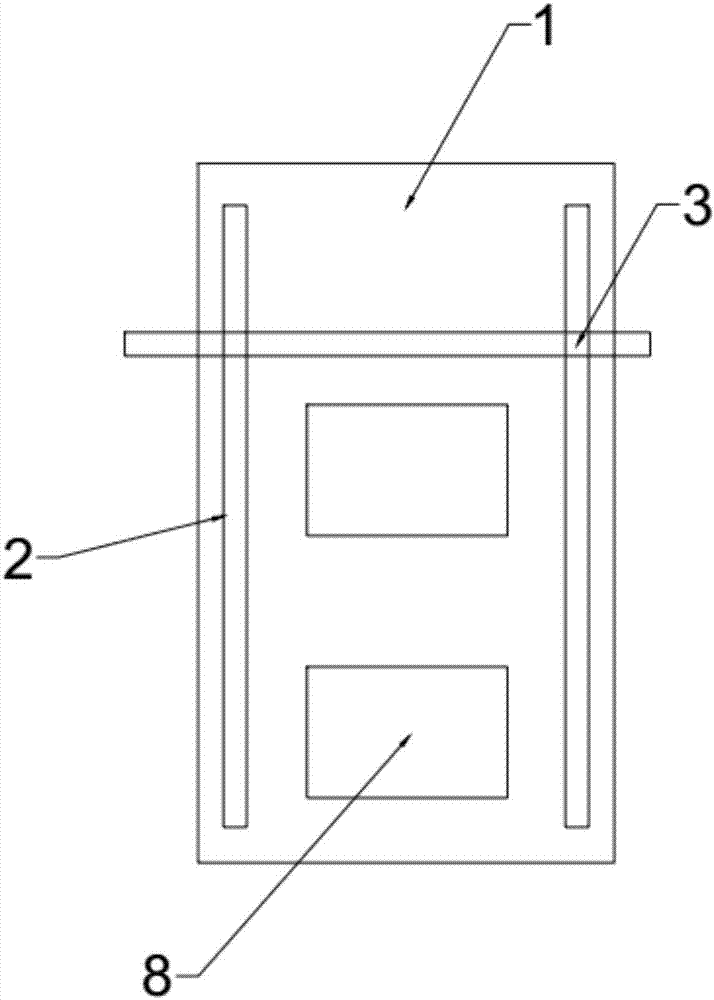

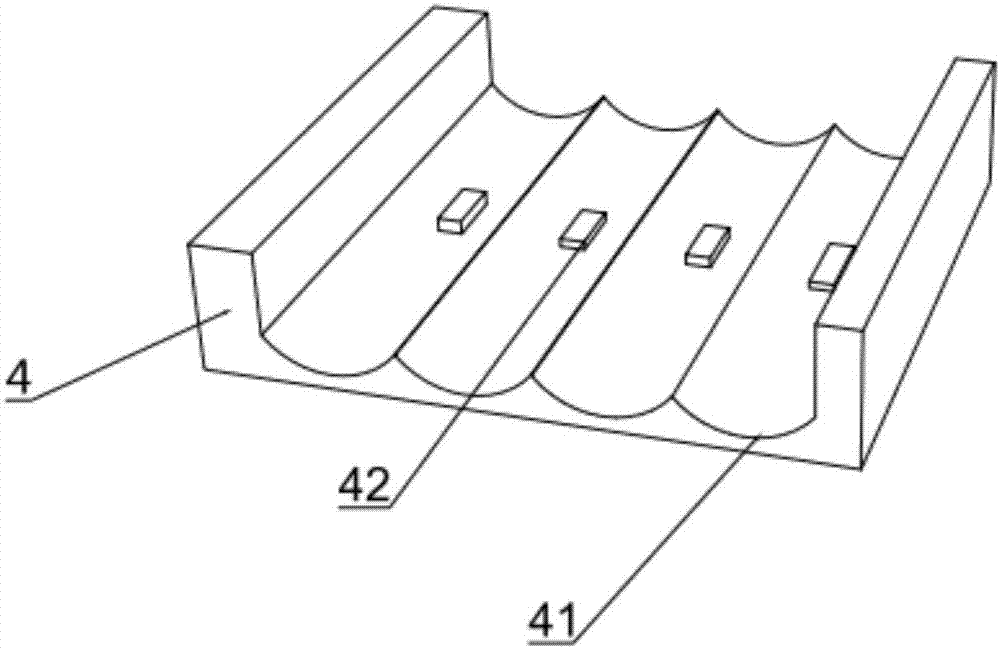

[0019] Such as Figure 1-Figure 4 As shown, a new type of cylindrical lithium battery automatic material transfer device includes an operation console 1, on which slide rails 2 parallel to each other are provided, support columns 3 are respectively provided on the slide rails 2, and support columns 3 are provided with Concave turning groove 4 is arranged, and several magnets 42 are equidistantly arranged on concave turning groove 4; A cylinder 6 is provided, a turning motor 7 is arranged on the cylinder 6, and a turning shaft 7 is arranged between the turning motor 7 and the connecting shaft 51 .

[0020] Such as Figure 1-Figure 4 As shown, a new type of cylindrical lithium battery automatic material transfer device includes an operation console 1, on which slide rails 2 parallel to each other are provided, support columns 3 are respectively provided on the slide rails 2, and support columns 3 are provided with Concave turning groove 4 is arranged, and several magnets 42 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com