A super-span multi-order prestressed steel truss structure and its construction method

A prestressed steel truss, steel truss technology, applied in building construction, architecture, photovoltaic power generation and other directions, can solve the problem of the size and distribution of the internal force of the reticulated shell components that do not match the design, the adverse effects of the mechanical properties of the chord support structure, and the poor use effect. and other problems, to achieve the effect of high construction efficiency, avoiding the time for repeated adjustment of the cable force, and high construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

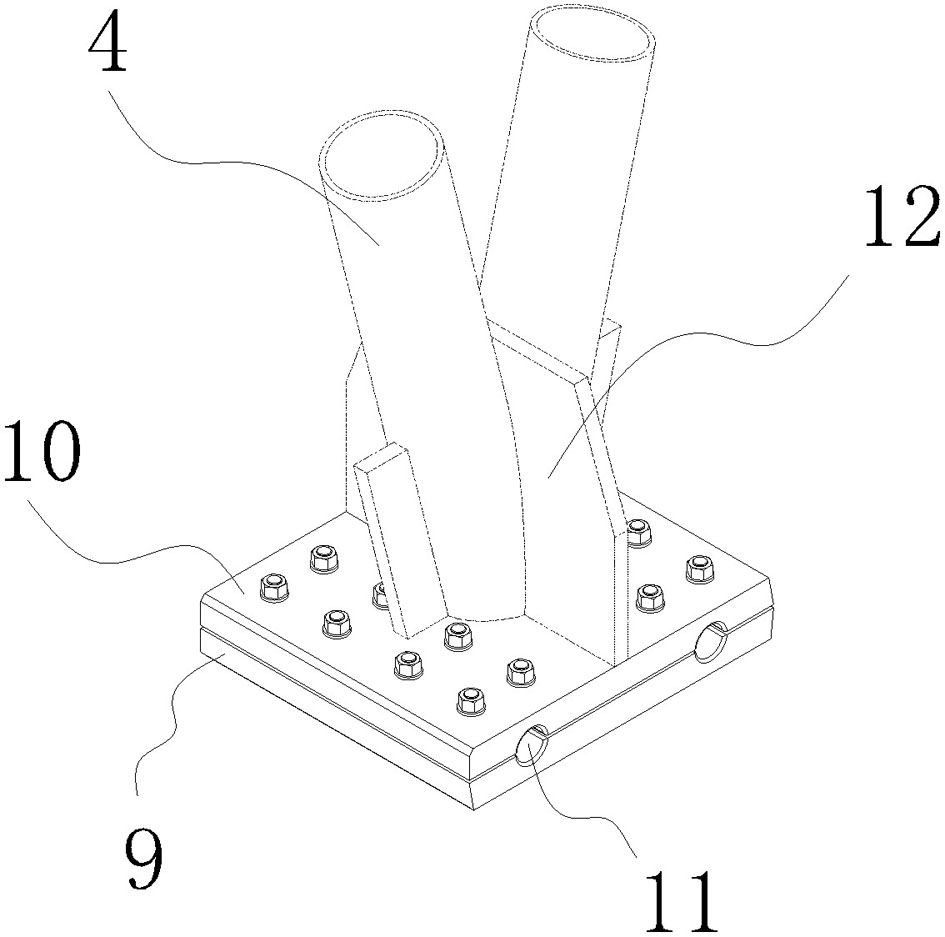

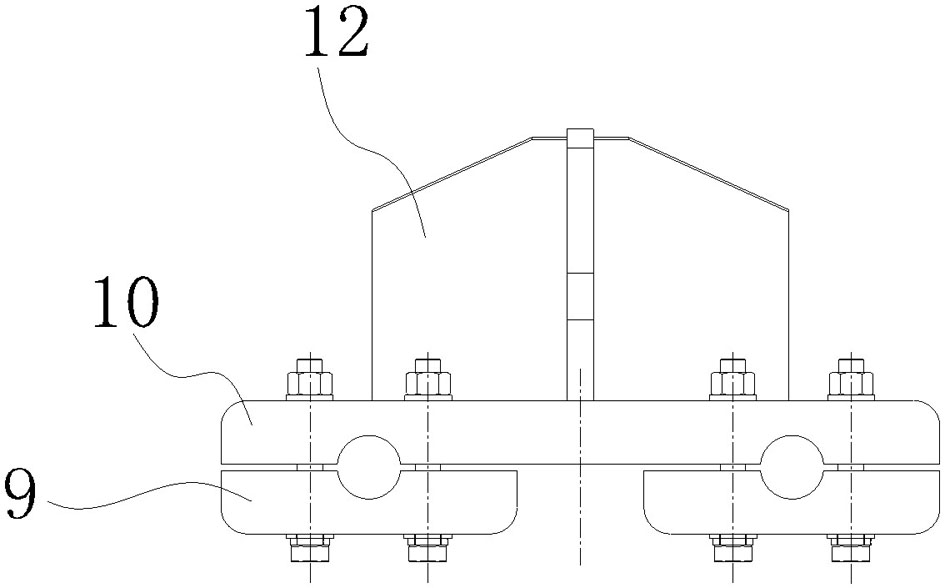

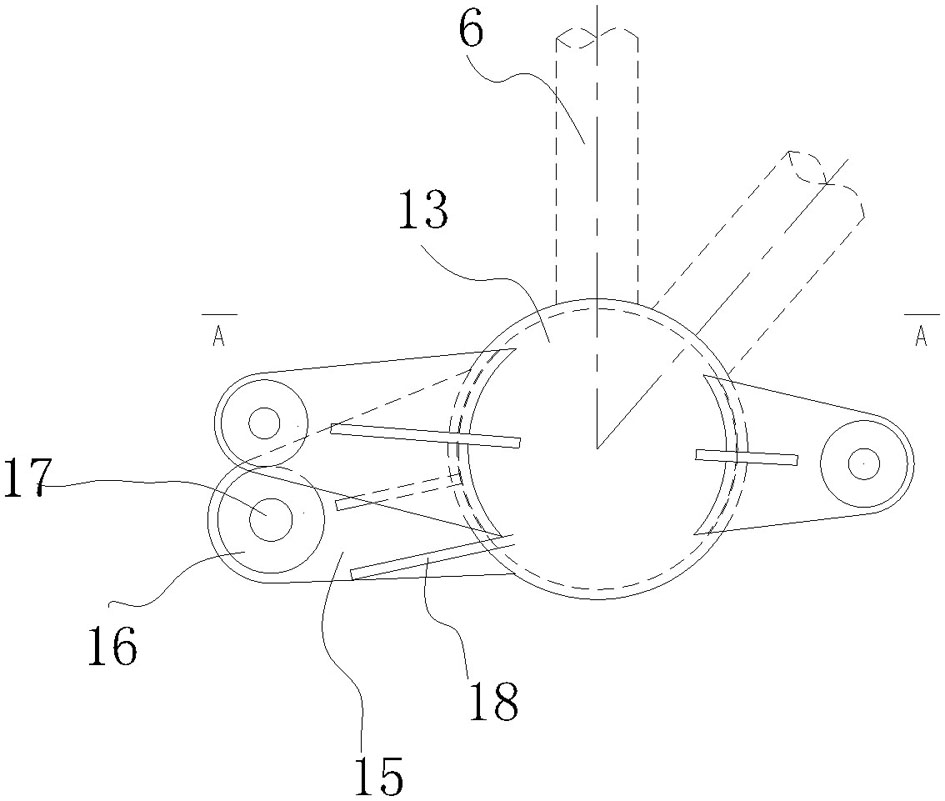

[0059] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, a super-large-span multi-order prestressed steel truss structure includes a steel truss 1 and a double-cable lower chord node fastening device 2. The bottoms of the two ends of the steel truss 1 are respectively provided with universal ball hinge nodes 3, so Below the steel truss 1, there are several continuously distributed double-cable lower chord node fastening devices 2, and the steel truss 1 and the double-cable lower chord node fastening devices 2 are positioned through V-shaped struts 4. The two ends below the steel truss 1 are respectively provided with multi-directional cable cross fixed nodes 5, the steel truss 1 and the multi-directional cable cross fixed nodes 5 are positioned by the multi-chord support rods 6, and the double-cable lower chord nodes are fastened. The dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com