Scintillation crystal unit sheet, array module, and detector

A scintillation crystal array and scintillation crystal technology, which is applied to scintillation components, instruments, measuring devices, etc., can solve the problems of square module cutting size deviation, increased production cost, and large-length cutting size deviation, so as to avoid defective products, Improve measurement accuracy and reliability, avoid mutual influence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Scintillation crystal unit chip

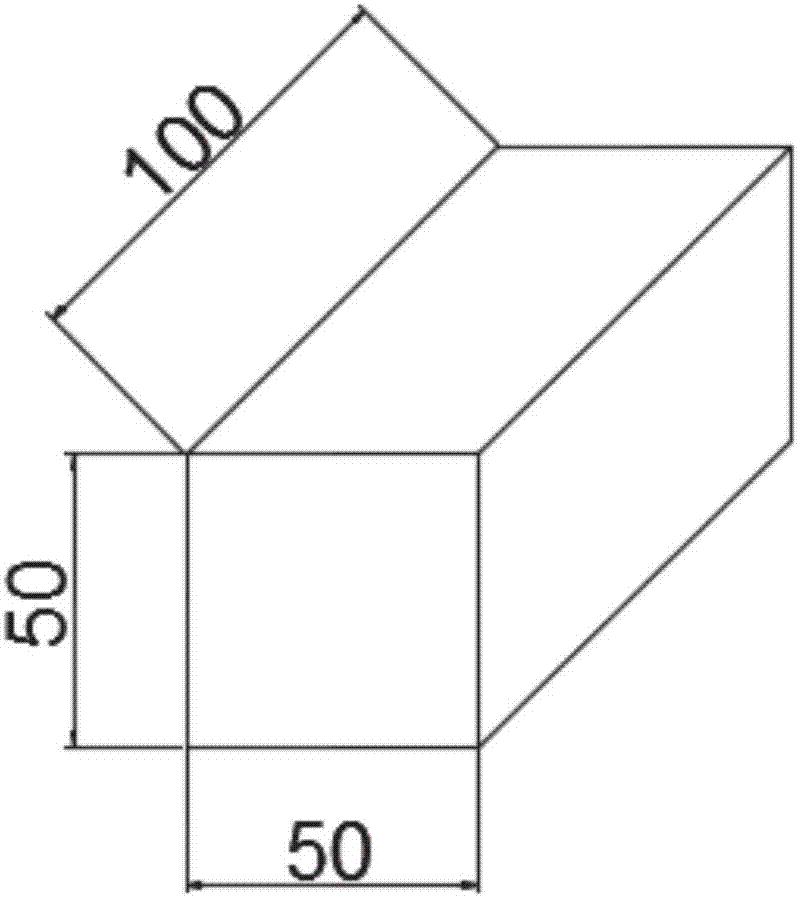

[0039] The size of the scintillation crystal in this embodiment is 50mm*50mm*100mm, see figure 1 , where the end face of 50mm*50mm is the clear surface, and the rest of the face is the side.

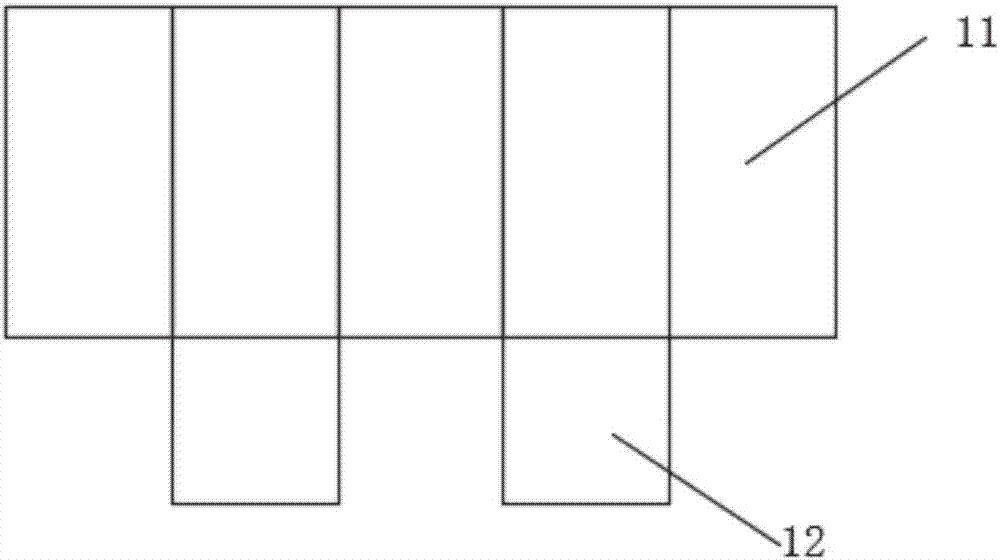

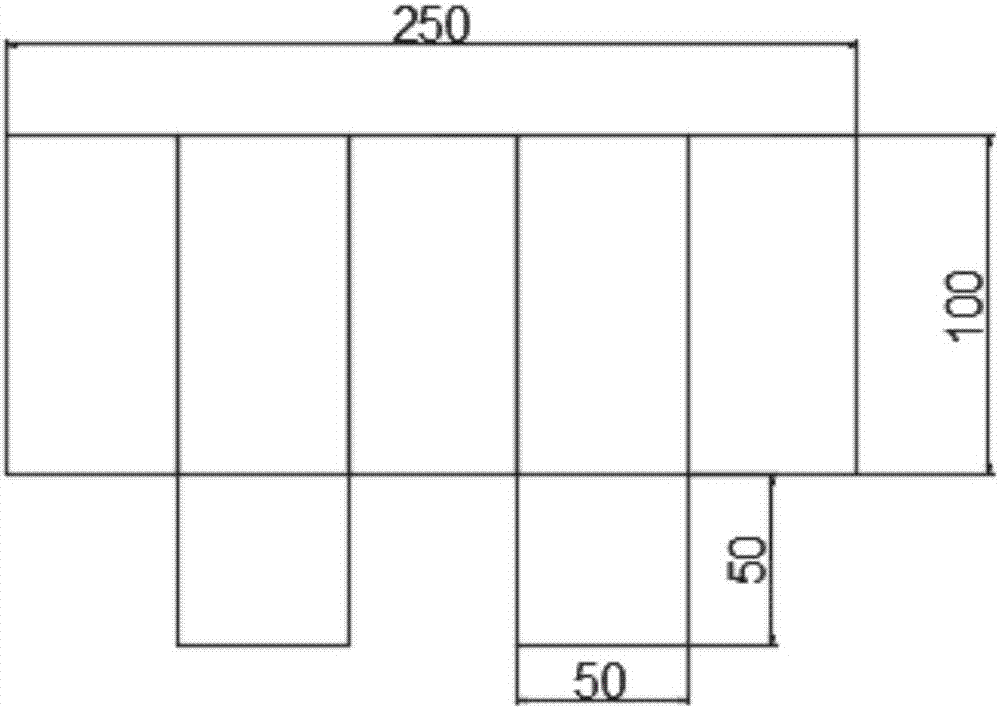

[0040] In this embodiment, the inclusion is a reflective film unit, such as figure 2 As shown, it is composed of a main body part 11 and a positioning part 12, the size of the main body part 11 is 250mm*100mm, and the size of the positioning part 12 is 50mm*50mm.

[0041] Apply glue evenly on each side of the scintillation crystal and the light-transmitting surface perpendicular to the side, and the reflective film unit presses figure 2 and image 3 The shown creases are turned over to form an upward concave space 21 and a downward concave space 22, see Figure 4 .

[0042] Arrange the glued crystals neatly in the concave space formed by the reflective film unit, bond the sides of the scintillation crystals to the main body 11 ...

Embodiment 2

[0044] Embodiment 2 scintillation crystal array module

[0045] Making two scintillation crystal units A1 of Embodiment 1 # , put two scintillation crystal units A1 according to Figure 7 Stacked in the same way, and glue is applied between the two scintillation crystal units, and clamped by precision vise clamps. Figure 7 The main body part 71 of the reflective film unit in the upper and lower two scintillation crystal unit pieces wraps four scintillation crystals 72 respectively. After curing, a scintillation crystal array module of 100mm*100mm*100mm can be obtained, such as Figure 8 As shown, the main body part 81 of the reflective film unit in the upper and lower scintillation crystal unit pieces wraps four scintillation crystals 82 respectively. The obtained scintillation crystal array module is denoted as B1 # .

[0046] It should be noted that, in this embodiment, after the side surface of the crystal unit is pasted to the main body of the reflective film, the li...

Embodiment 3

[0047] Embodiment 3 scintillation crystal array module

[0048] The manufacturing method of the scintillation crystal unit sheet is the same as that of the embodiment 1, and the manufacturing method of the scintillation crystal array module is the same as that of the embodiment 2, except that parameters such as the scintillation crystals, size, and number of array components are different. See Table 1 for details.

[0049] Table 1

[0050] Array module serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com