Carbon fiber globe-roof and manufacturing method therefor

A technology of carbon fiber balls and manufacturing methods, which is applied in the field of electroacoustic devices, can solve problems such as poor mechanical properties, material layering, and unsightly appearance, and achieve the effects of improving sound quality, reducing thickness, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Combine below Figure 1 to Figure 7 The present invention is described in detail.

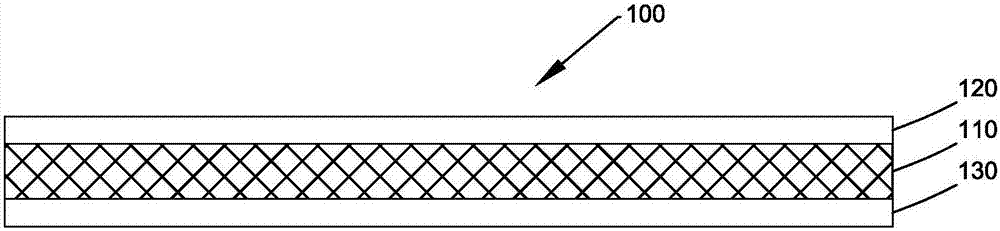

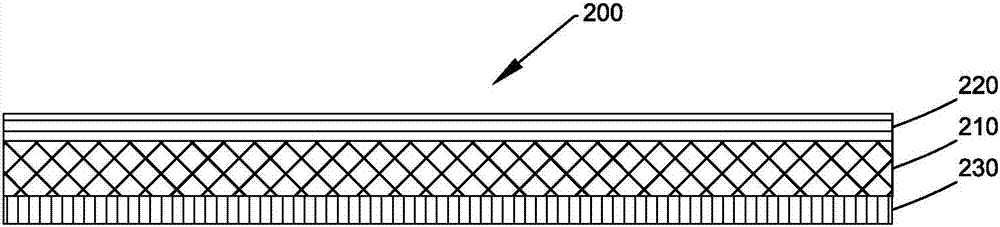

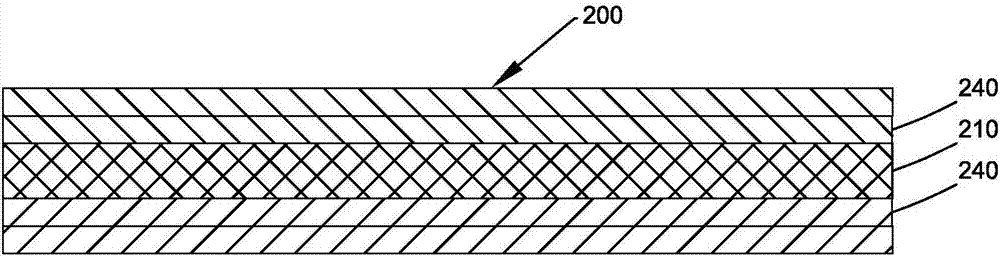

[0022] In order to overcome the problems in the prior art that the dome structure is fragile, easily delaminated, insufficient in strength, and poor in appearance, the present invention provides a dome structure prepared by using carbon fiber materials, such as figure 1 As shown, the embodiment of the present invention provides a carbon fiber dome 100, including a foam material layer 110, a first carbon fiber layer 120 located on the upper end surface of the foam material layer 110 and / or a carbon fiber layer 120 located on the foam material layer 110 The second carbon fiber layer 130 on the lower end surface, the carbon fiber dome in the embodiment of the present invention can be provided with a carbon fiber layer on one side of the foam material layer 110, and can also be provided with a carbon fiber layer on both sides to further improve performance and provide combined performance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com