Wide-application-range forage filament rubbing machine

A technology that adapts to the scope and fodder, and is applied in the direction of feed, application, agricultural machinery and implements, etc. It can solve the problems of small application range, hard sting of silage, and difficult storage, etc., and achieves wide application range, good kneading effect, The effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

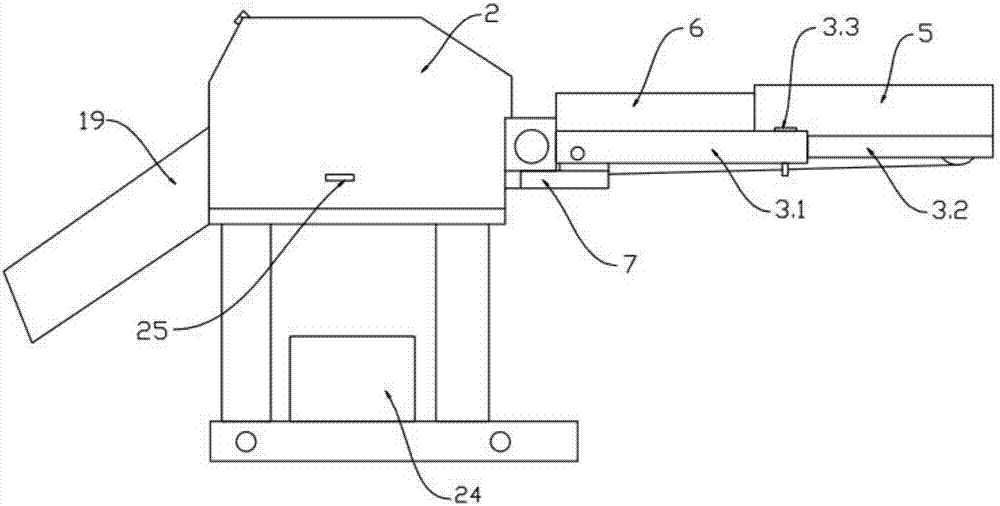

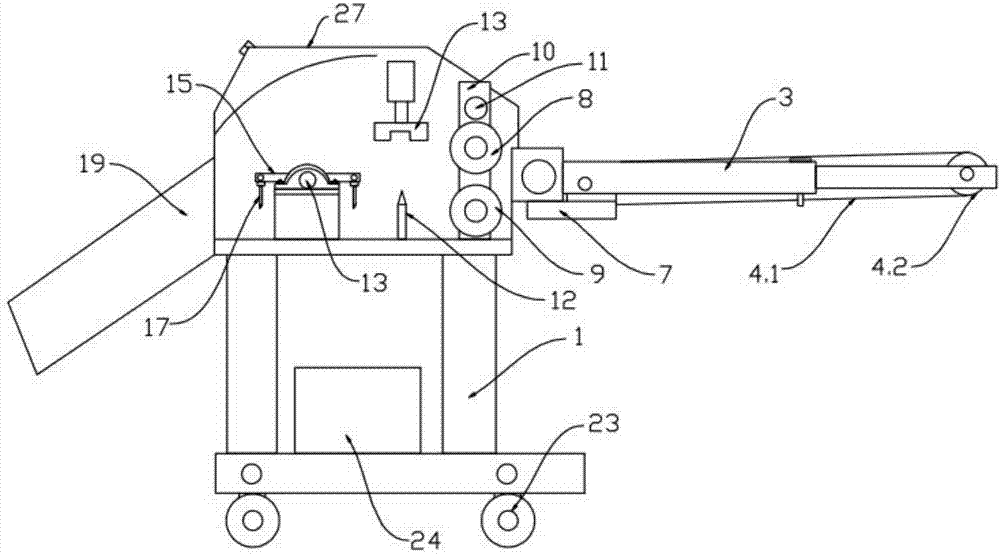

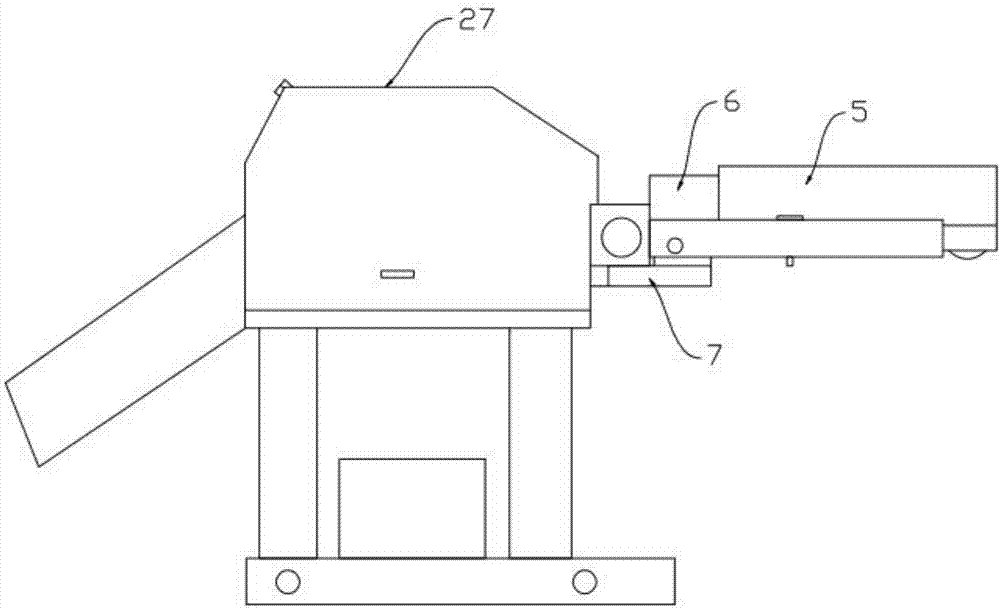

[0023] In conjunction with the accompanying drawings, a forage kneading machine with a wide range of adaptability includes a frame 1, a housing 2 is provided on the frame 1, a kneading device and an extruding device are arranged in the housing 2, Described frame 1 is hingedly provided with telescoping rod 3, and described telescoping rod 3 is provided with belt conveying device 4, and one end of described telescoping rod 3 is provided with baffle plate-5 and the other end is provided with plugging in baffle plate. Baffle plate two 6 in one 5, described baffle plate one 5 and baffle plate two 6 play the effect that prevents forage from falling, and described frame 1 is positioned at telescopic rod 3 place and is provided with to telescopic rod 3 to play a role. The blocking rod 7 with a position-limiting effect, the extruding device includes an upper feeding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com