Degradable woven occluder

An occluder and woven mesh technology, applied in the field of medical devices, can solve the problems of abrasion of surrounding tissues, third-degree conduction block of patients, intolerance of occluder, etc., to achieve excellent effect, avoid complications of occluder, Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

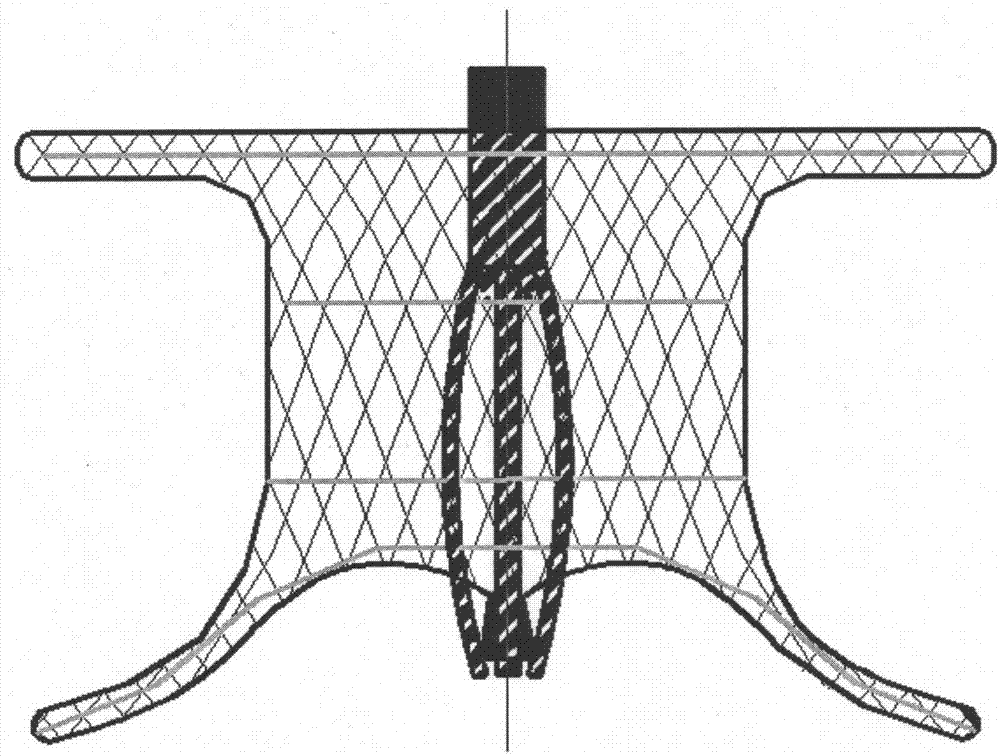

[0031] Because the mechanical properties of the degradable wire, such as superelasticity, are much weaker than those of the shape memory alloy wire, in order to ensure the expected effect of the occluder in clinical applications, it is necessary to compensate the occluder structurally. The compensation scheme is as follows: Figure 1-Figure 3 As shown, at the upper end of the occluder, that is, a cut pipe (i.e. the connection structure 3) is added in the braided wire mesh 2 at the distal end of the braided degradable occluder of the present invention, and the upper end of the cut pipe is fixedly connected with the distal end 1 .

[0032] The lower end of the cut pipe is evenly split into 4 connecting rods 3-1, such as Figure 4 As shown, each connecting rod 3-1 is gathered in the axial direction of the cut pipe, such as figure 1 As shown, when the occluder is released, the cut tubing is assisted by the pullback of the auxiliary wire, and each connecting rod 3-1 at the lower e...

Embodiment 2

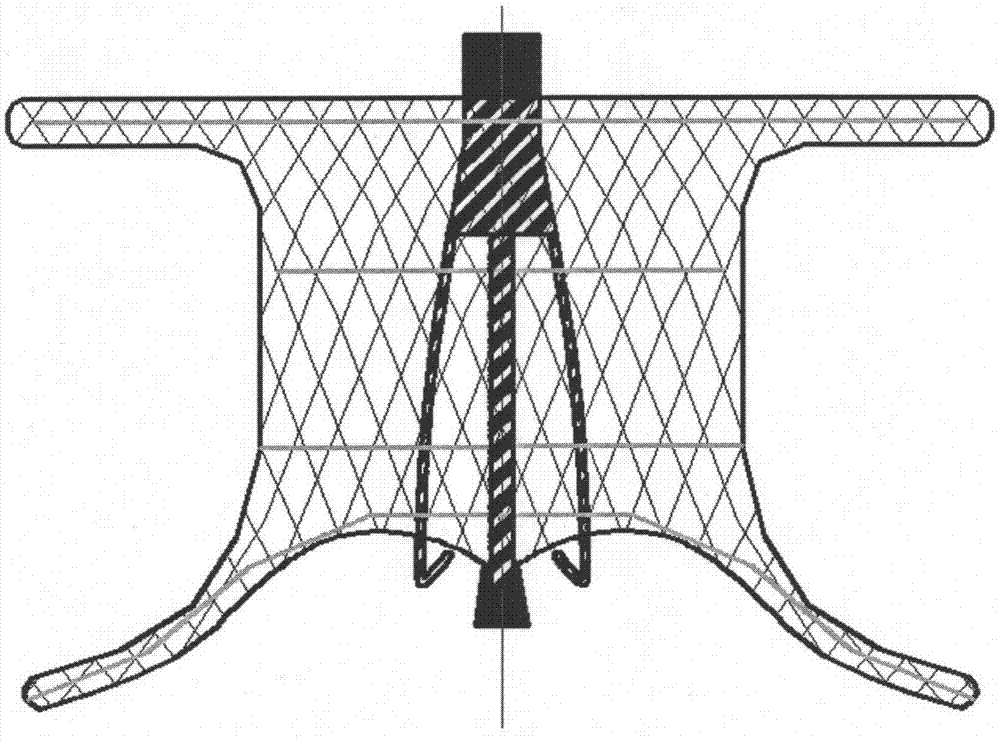

[0036] Such as figure 2 As shown, the lower end of the cut pipe is evenly split into four connecting rods 3-1, and each connecting rod 3-1 is gathered in the axial direction of the cutting pipe, and each connecting rod 3-1 on the cutting pipe is There is a curved hook 3-2 at the head end of the occluder. When the occluder is released, the cut tubing is assisted by the pull-back of the auxiliary wire, and each connecting rod 3-1 at the lower end of the cut tubing passes through the wire weaving of the occluder. The grid gap of the net 2 is drawn towards the axial direction, and the hook 3-2 is hooked to tighten the wire / grid of the wire braided net 2 near the proximal end 4 or the proximal end 4 of the occluder at the same time, so that the sealing The linear distance between the two ends of the occluder is consistent with the length of the cut pipe. At this time, the occluder is stable in the shape of "I" to ensure that the occluder does not fall off. At the same time, both t...

Embodiment 3

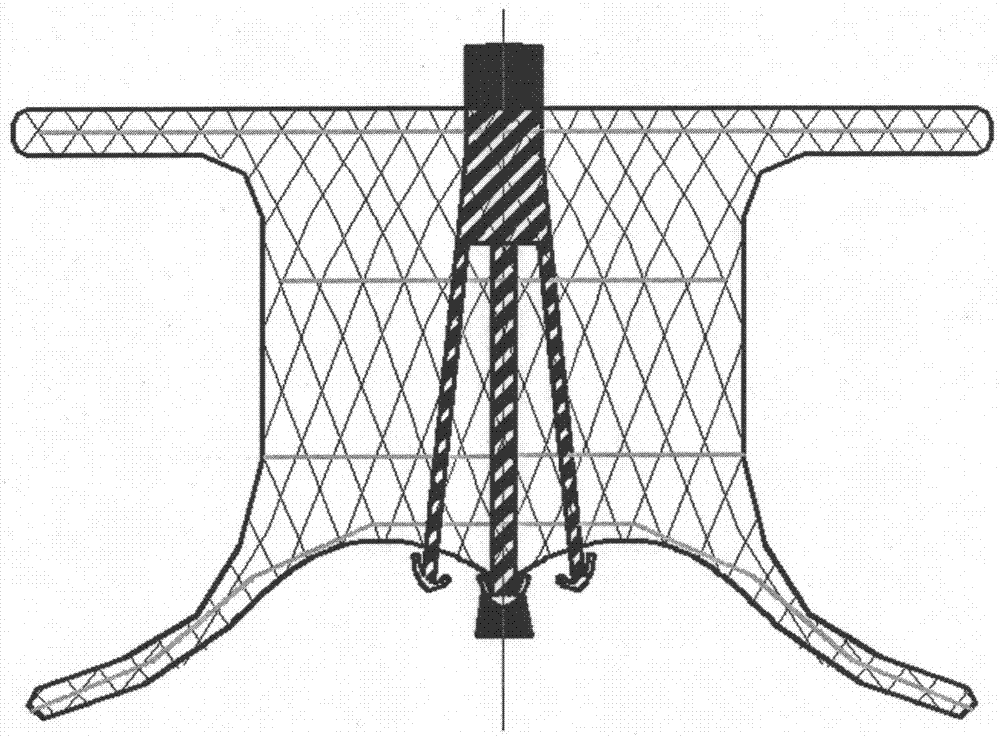

[0039] Such as image 3 As shown, the lower end of the cutting pipe is evenly split into four connecting rods 3-1, and each connecting rod 3-1 may not be gathered in the axial direction of the cutting pipe, and it has one or two bends at the head end. Hook 3-2, when the occluder is released, the cut tubing is assisted by the pullback of the auxiliary wire, and each connecting rod 3-1 at the lower end of the cut tubing passes through the grid of the wire braided mesh 2 of the occluder Gap, hook 3-2 to tighten the proximal end 4 of the occluder or the wire / grid of the wire braided mesh 2 near the proximal end 4, so that the linear distance between the two ends of the occluder is consistent with the length of the cut pipe At this time, the occluder is stable in the shape of "I", ensuring that the occluder does not fall off, and at the same time, both the disk surface 2-1 and the waist 2-2 have the effect of occlusion, achieving the effect of mechanical supplementation.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com