Makeup removing lotion gel and preparation method thereof

A technology for removing makeup milk and gel, which is applied to the field of makeup removing products and their preparation, can solve the problems of affecting the makeup removing effect, poor makeup removing ability, poor excessive oil rinsing, etc., so as to achieve the improvement of makeup removal speed and comprehensive makeup removal effect, improve the removal ability, Powerful makeup remover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 prepares cleansing milk gel (1)

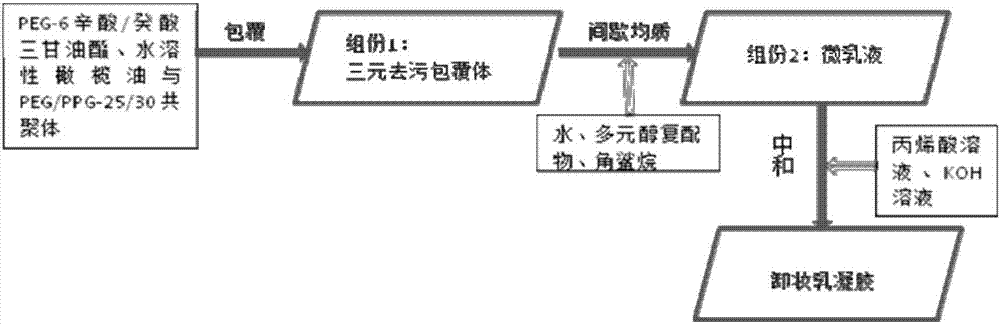

[0036] 1. Preparation of component 1 - ternary decontamination microcapsule coating

[0037] (1) Add PEG-6 caprylic / capric triglyceride (40kg), water-soluble olive oil (8.0kg) and PEG / PPG-25 / 30 copolymer (2kg) into the sterilized vacuum reactor, start stirring, Heat to 80°C and hold for 15 minutes;

[0038] (2) Cool down to 70°C, evacuate to -0.08Mpa, and stir for 15 minutes until micelles are formed, the material liquid is transparent and clear, and a homogeneous phase is formed;

[0039] (3) Cool down to below 45°C and discharge for later use.

[0040] 2. Preparation of component 2 - microemulsion

[0041] (1) Add component 1 (8kg) and polyol compound (the specific composition is glycerin 6kg, dipropylene glycol 3kg, 1,3-butanediol 1kg) into purified water (60kg), start stirring, and heat to 80°C;

[0042] (2) Add squalane (0.5kg) to the system, homogenize intermittently for 8 minutes, until the system changes from m...

Embodiment 2

[0045] Embodiment 2 prepares cleansing milk gel (two)

[0046] 1. Preparation of component 1 - ternary decontamination microcapsule coating

[0047](1) Add PEG-6 caprylic acid / capric triglyceride (80.0kg), water-soluble olive oil (10kg) and PEG / PPG-25 / 30 copolymer (5.0kg) into the sterilized vacuum reactor, and start stirring , heated to 80°C, and held for 15 minutes;

[0048] (2) Cool down to 70°C, evacuate to -0.08Mpa, and stir for 15 minutes until micelles are formed, the material liquid is transparent and clear, and a homogeneous phase is formed;

[0049] (3) Cool down to 45°C and discharge for later use.

[0050] 2. Preparation of component 2 - microemulsion

[0051] (1) Add component 1 (9.0kg) and polyol compound (the specific composition is glycerin 6kg, dipropylene glycol 3kg, 1,3-butanediol 1kg) into purified water (60kg), start stirring, Heating to 70°C;

[0052] (2) Add squalane (0.3kg) to the system, homogenize intermittently for 8 minutes, until the system ch...

Embodiment 3

[0055] Embodiment 3 prepares cleansing milk gel (three)

[0056] 1. Preparation of component 1 - ternary decontamination microcapsule coating

[0057] (1) Add PEG-6 caprylic acid / capric triglyceride (50.0kg), water-soluble olive oil (9kg) and PEG / PPG-25 / 30 copolymer (3.0kg) into the sterilized vacuum reactor, and start stirring , heated to 85°C and kept for 15 minutes;

[0058] (2) Cool down to 75°C, evacuate to -0.08Mpa, and stir for 20 minutes until micelles are formed, the material liquid is transparent and clear, and a homogeneous phase is formed;

[0059] (3) Cool down to 45°C and discharge for later use.

[0060] 2. Preparation of component 2 - microemulsion

[0061] (1) Add component 1 (6.0kg) and polyol compound (the specific composition is glycerin 6kg, dipropylene glycol 3kg, 1,3-butanediol 1kg) into purified water (60kg), start stirring, Heating to 78°C;

[0062] (2) Add squalane (0.5kg) to the system, homogenize intermittently for 8 minutes, until the system c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com