Two-stage pipeline type gas-liquid cyclone separator

A cyclone separator and pipeline-type technology, which is applied in the field of multiphase separation in oil and gas gathering and transportation systems, can solve problems such as obvious corrosion of blades, failure of separators, ice blockage, etc., to reduce the probability of crushing and rebound, and achieve high separation Efficiency, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

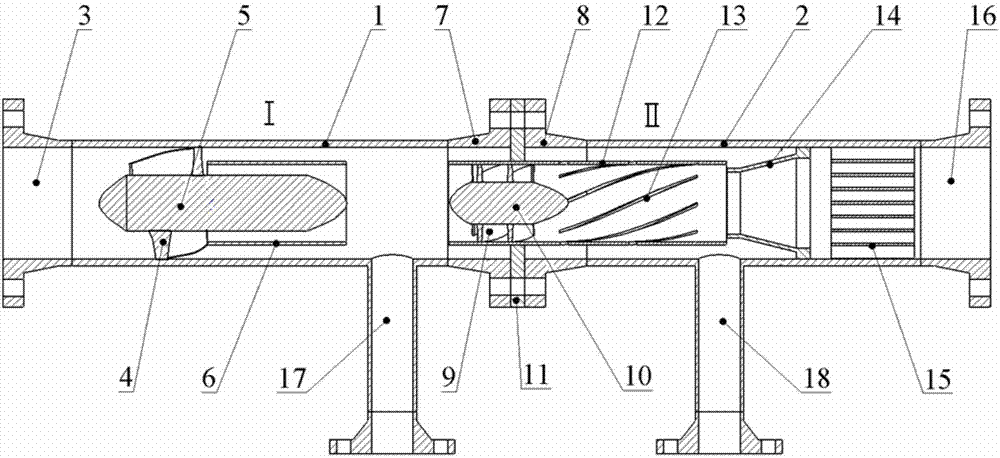

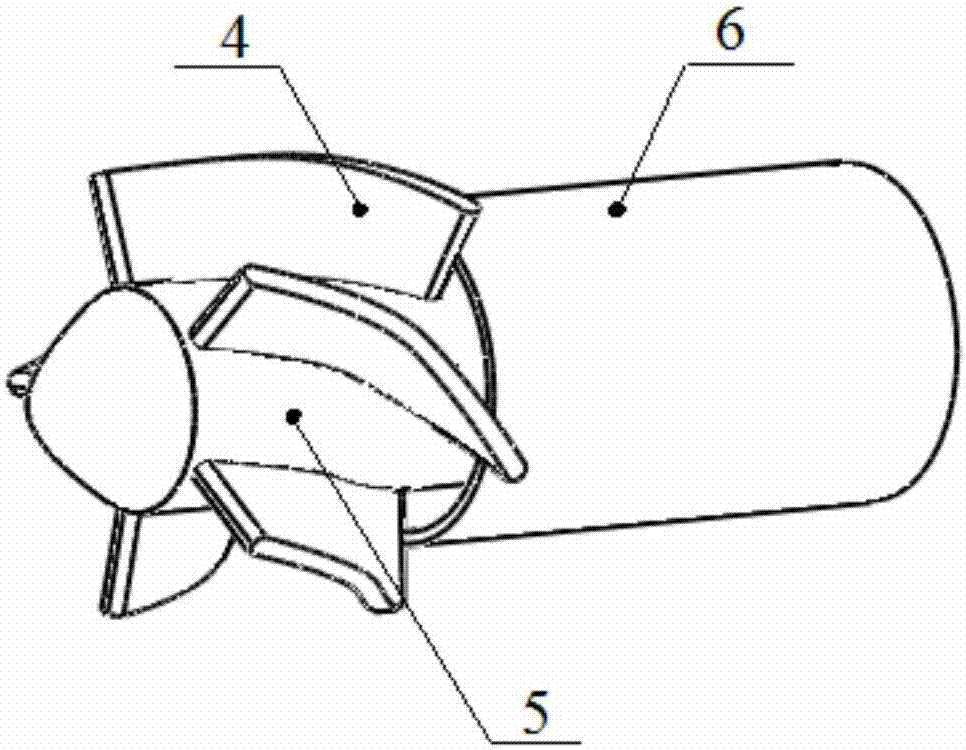

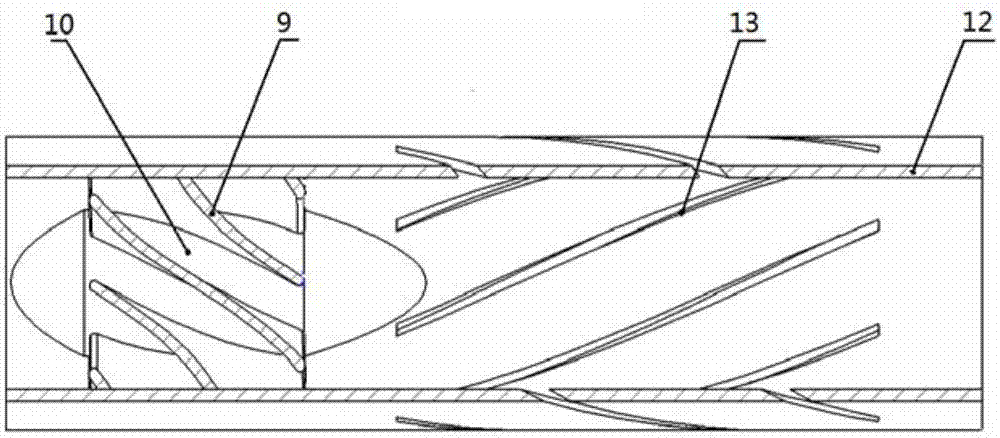

[0023] See attached figure 1 , a two-stage pipeline type gas-liquid cyclone separator, the separator is mainly composed of two parts, the first-stage separation module I and the second-stage separation module II, the two-stage separation module passes through the front flange 7 in the middle of the separator and the rear method The primary separation module I is mainly composed of the axial inlet 3, the primary guide vane 4, the guide body 5, the sleeve 6, and the front liquid discharge pipe 17; the primary guide vane 4 blade is spiral, The outer edge and the inner edge are respectively connected with the inner wall of the primary separation pipe (1) and the outer surface of the primary guide body 5; the sleeve 6 is adjacent to the primary guide vane 4 and connected with the tail of the blade; The barrel 6 is coaxial, extends horizontally inside the sleeve 6 and forms an annular cavity with the sleeve 6 . A front drain pipe 17 is provided at the bottom of the primary separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com