Uniform-light micro-optic resonance waste gas treatment device

A waste gas treatment device and low-light technology, which are applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of uneven distribution, high purification capacity, low purification efficiency, etc., and achieve obvious purification effect and improve purification efficiency. , the effect of compressing the space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

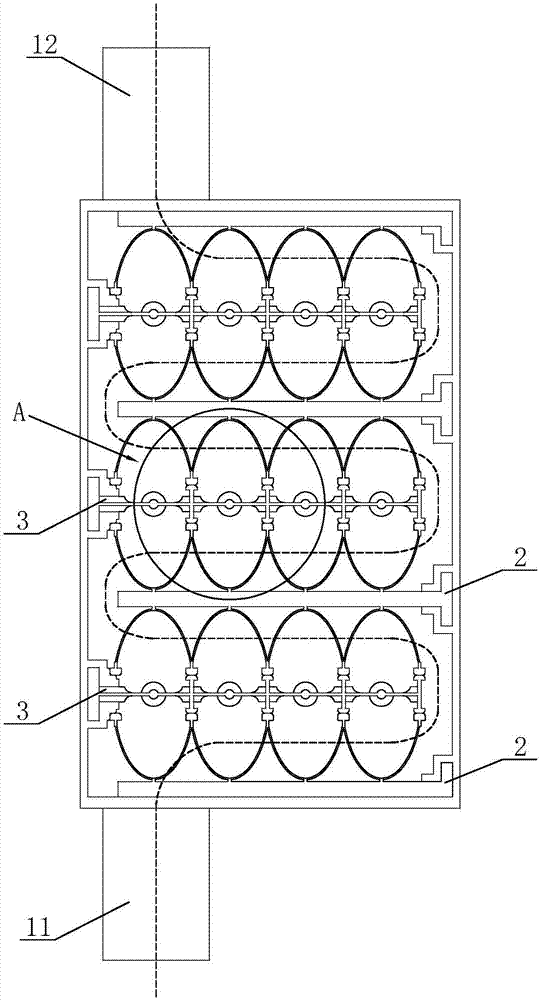

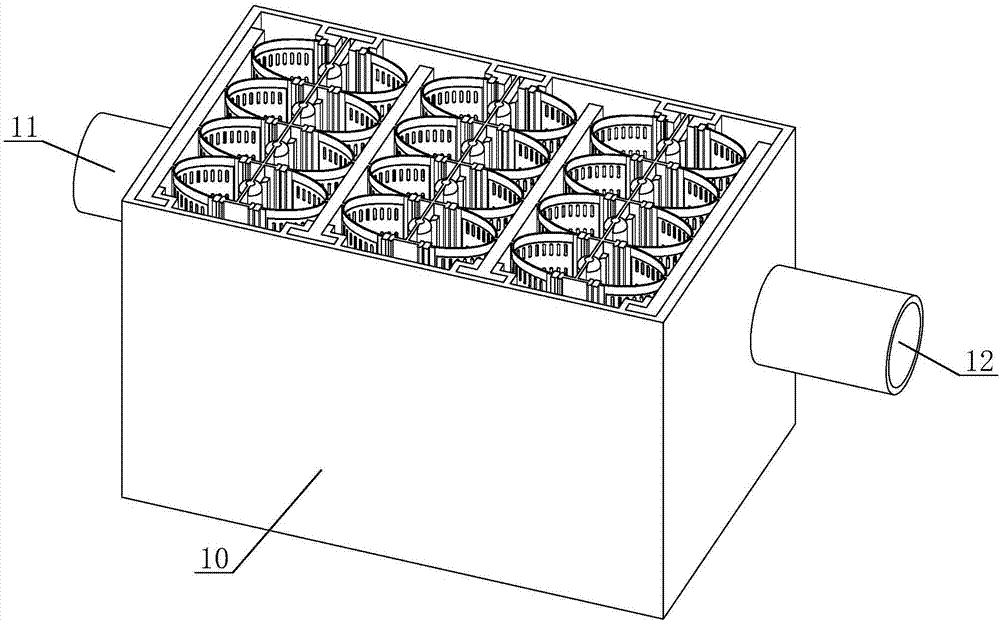

[0035] Such as figure 1 with image 3 The shown long-diameter low-light resonance exhaust gas treatment device includes a housing 10, an air inlet pipe 11 and an air outlet pipe 12, and the air inlet pipe 11 and the air outlet pipe 12 are fixed at both ends of the housing 10; inside the housing 10 are provided with a plurality of staggered ultraviolet components 3 and photocatalyst assembly 2.

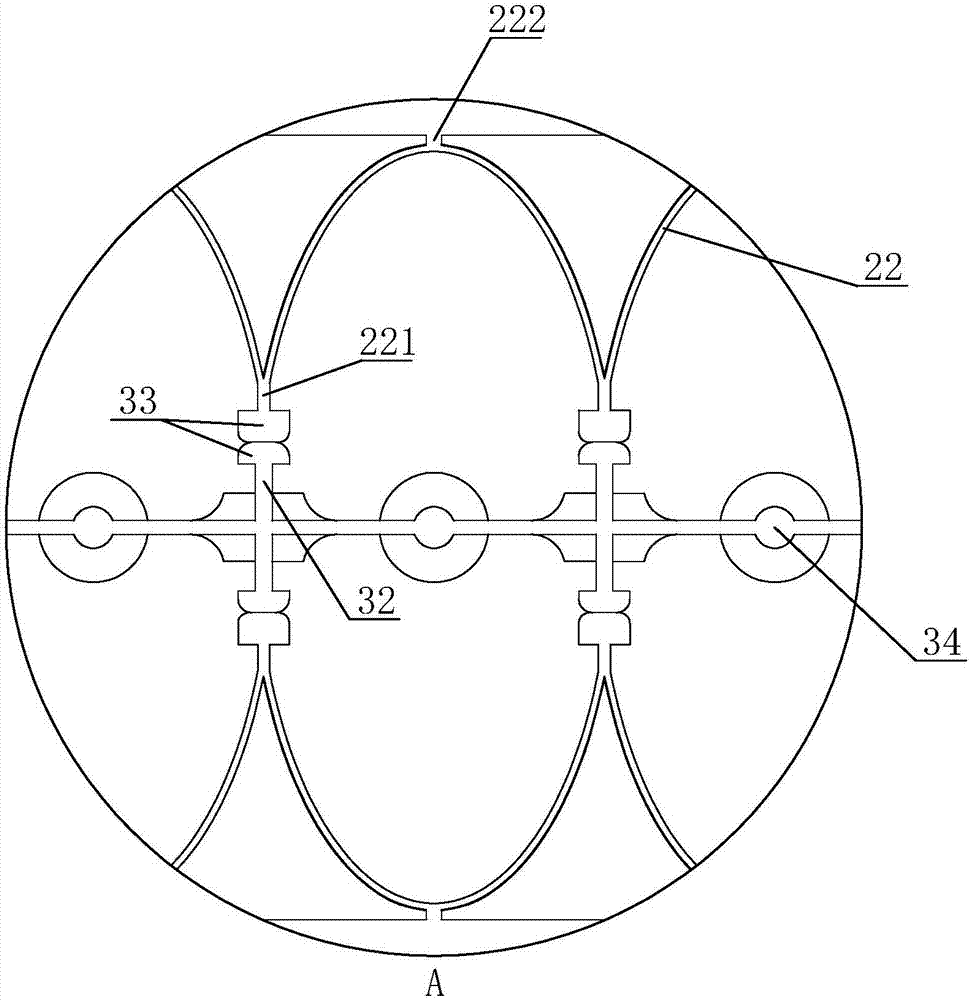

[0036] Such as Figure 5 As shown, the photocatalyst assembly 2 comprises a plate frame 20 and a photocatalyst plate 22, the photocatalyst plate 22 is fixed on the surface of the plate frame 20, and the photocatalyst plate 22 is a semicircular or parabolic air-permeable net plate; the plate frame 20 is an airtight plate structure, the end of the photocatalyst plate 22 close to the light frame 30 is the low light end 221, the two ends close to the plate frame 20 are the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com