Pipe cutting device for natural gas pipeline installation

A natural gas pipeline and cutting device technology, which is applied in the field of cutting devices for natural gas pipeline installation, can solve the problems of time-consuming and labor-intensive, reduced efficiency of natural gas pipeline installation, and low cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

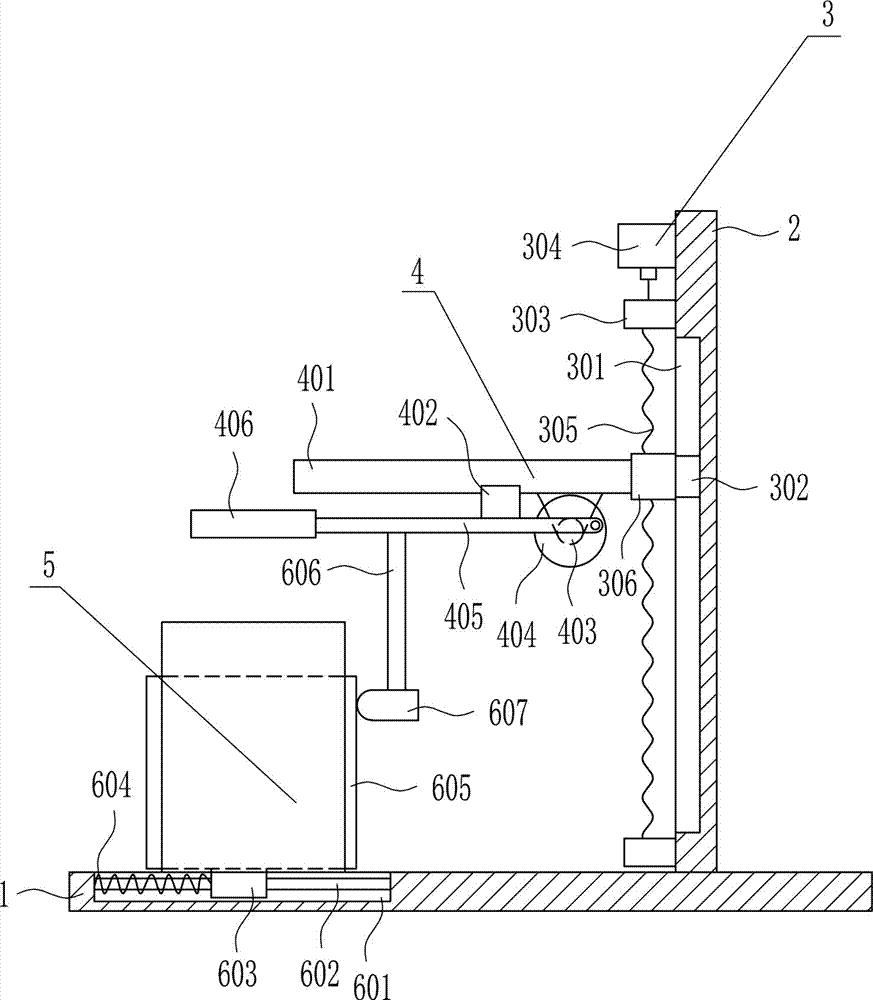

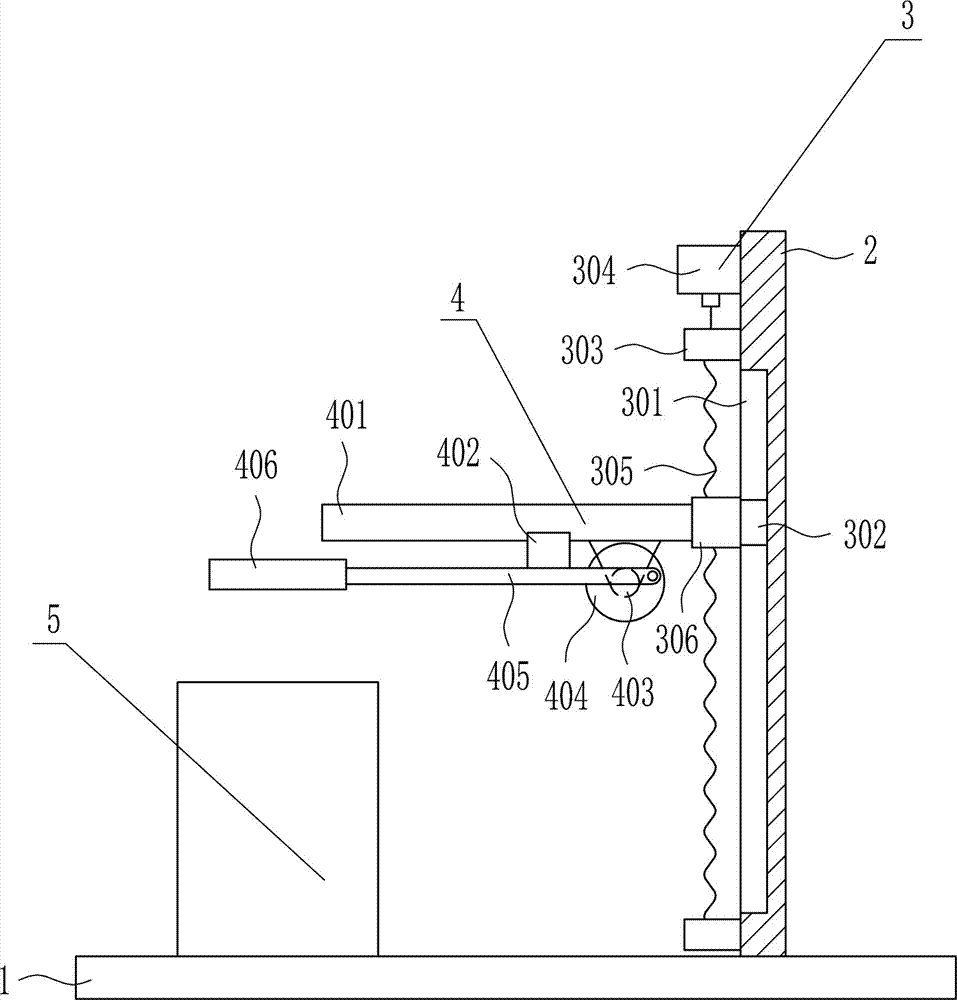

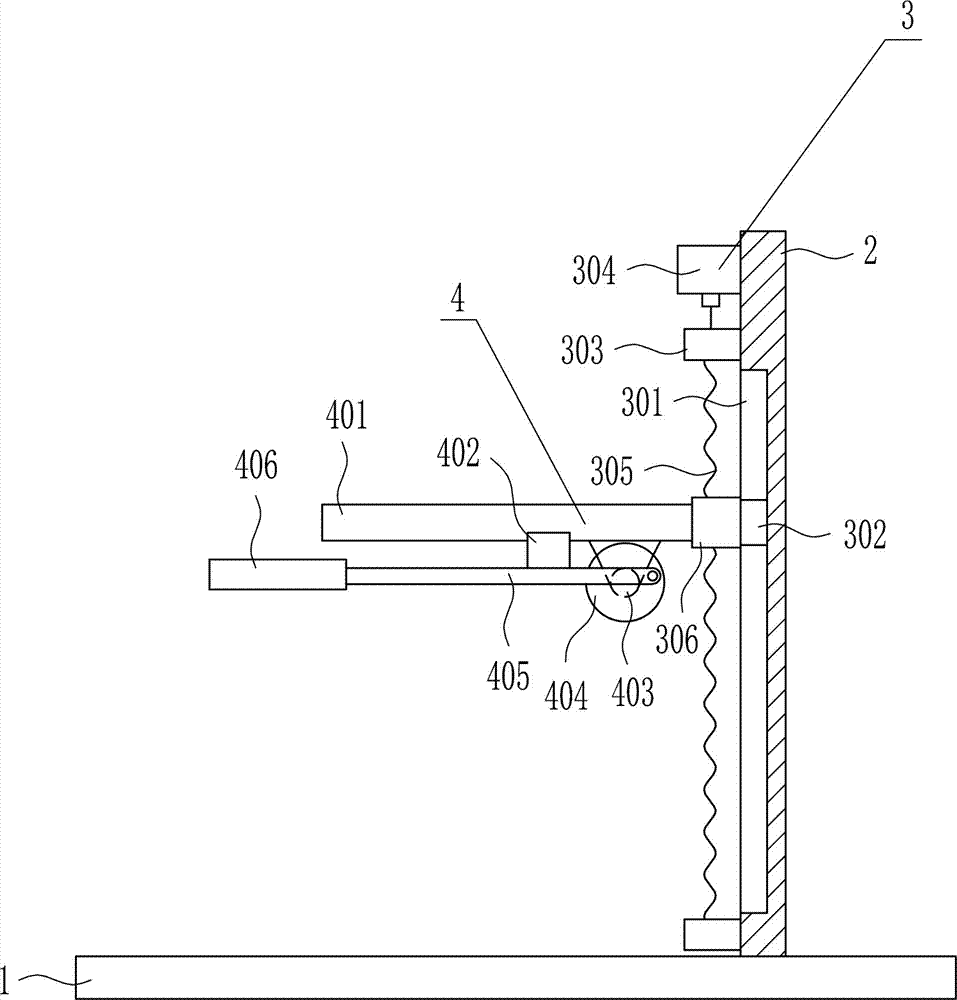

[0034] A pipe cutting device for natural gas pipeline installation, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, an up and down movement mechanism 3 and a cutting device 4. The top right side of the bottom plate 1 is vertically provided with a support plate 2, and the left side of the support plate 2 is provided with an up and down movement mechanism 3. The up and down moving mechanism 3 is provided with a cutting device 4 .

Embodiment 2

[0036] A pipe cutting device for natural gas pipeline installation, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, an up and down movement mechanism 3 and a cutting device 4. The top right side of the bottom plate 1 is vertically provided with a support plate 2, and the left side of the support plate 2 is provided with an up and down movement mechanism 3. The up and down moving mechanism 3 is provided with a cutting device 4 .

[0037] The up and down movement mechanism 3 includes a first slide block 302, a bearing seat 303, a first motor 304, a screw mandrel 305 and a nut 306, and the left side of the support plate 2 is vertically provided with a chute 301, and the chute 301 is provided with a The first sliding block 302 that is slidingly fitted, the left side of the support plate 2 on the upper and lower sides of the chute 301 is equipped with a bearing seat 303 through bolts, and the left side of the support plate 2 on the upper side of the u...

Embodiment 3

[0039] A pipe cutting device for natural gas pipeline installation, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, an up and down movement mechanism 3 and a cutting device 4. The top right side of the bottom plate 1 is vertically provided with a support plate 2, and the left side of the support plate 2 is provided with an up and down movement mechanism 3. The up and down moving mechanism 3 is provided with a cutting device 4 .

[0040] The up and down movement mechanism 3 includes a first slide block 302, a bearing seat 303, a first motor 304, a screw mandrel 305 and a nut 306, and the left side of the support plate 2 is vertically provided with a chute 301, and the chute 301 is provided with a The first sliding block 302 that is slidingly fitted, the left side of the support plate 2 on the upper and lower sides of the chute 301 is equipped with a bearing seat 303 through bolts, and the left side of the support plate 2 on the upper side of the u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap