Method for assembling SCARA robot through digital image processing technology

A technology of digital images and assembly methods, applied in image data processing, image enhancement, image analysis and other directions, can solve the problems of robots not being able to adapt in time, limiting the flexibility and work efficiency of industrial robots, and task failures, achieving improved adaptability, The effect of improving production efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing.

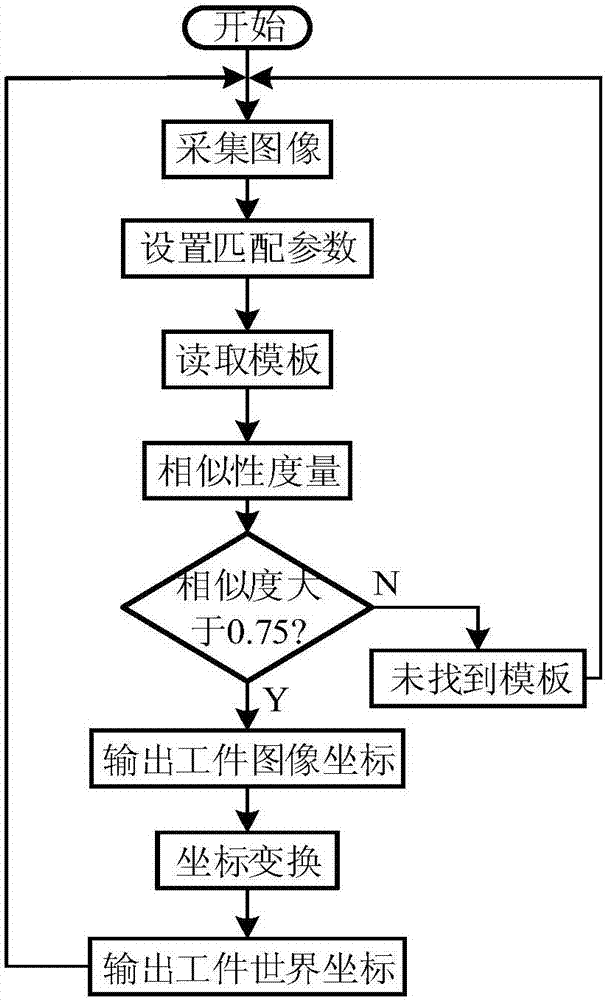

[0026] Such as figure 1 Shown: a kind of SCARA robot assembly method utilizing digital image processing technology, comprises the following steps:

[0027] Step1. Install the industrial camera, install the camera directly above the working area of the robot, and adjust the focal length of the camera so that the entire working area is within the field of view of the camera;

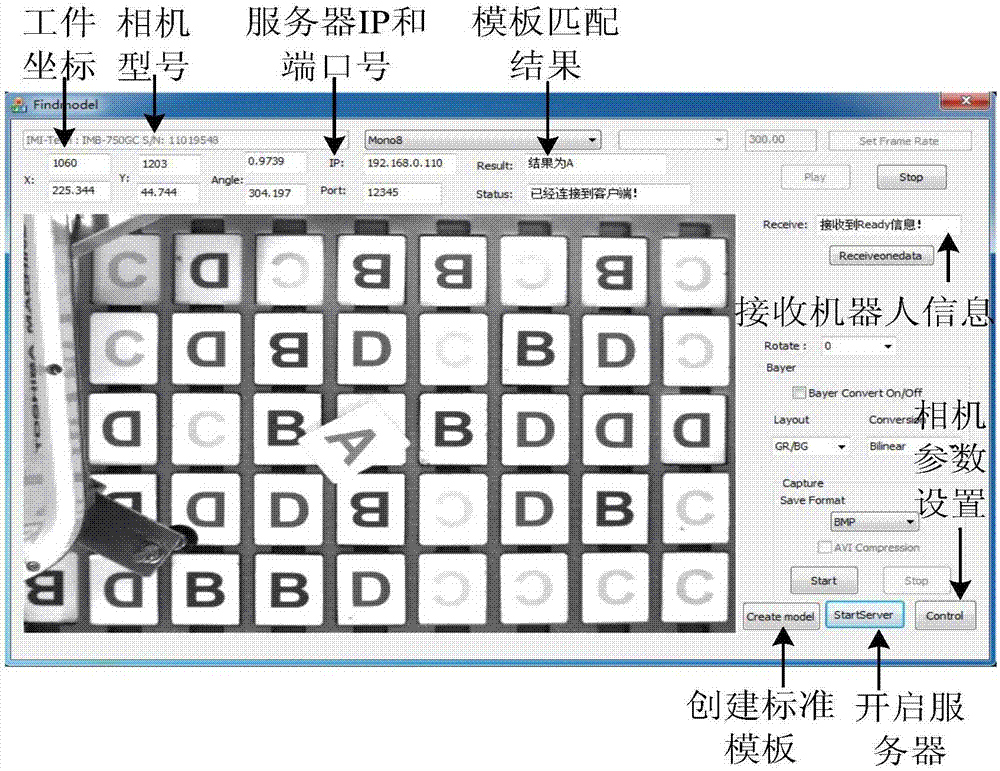

[0028] Using the Korean IMI tech Amazon2 series industrial camera, in the case of including the camera class library, read the data of the camera by instantiating the camera handle class, and use the OneFrameGrab function to obtain a frame of image data of the camera and save the data, and then use the Halcon The reading function read_image is used to read the saved data and get an image, thus realizing the online reading function of the camera with Halcon;

[0029] Step 2. Camera calibration mainly us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com