Reactive extrusion functionalized SIS material, and preparation method thereof

A reactive extrusion and functionalization technology, applied in the chemical industry, can solve the problems of limited use range and poor binding force of inorganic materials, and achieve the effect of increasing mechanical properties and increasing application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

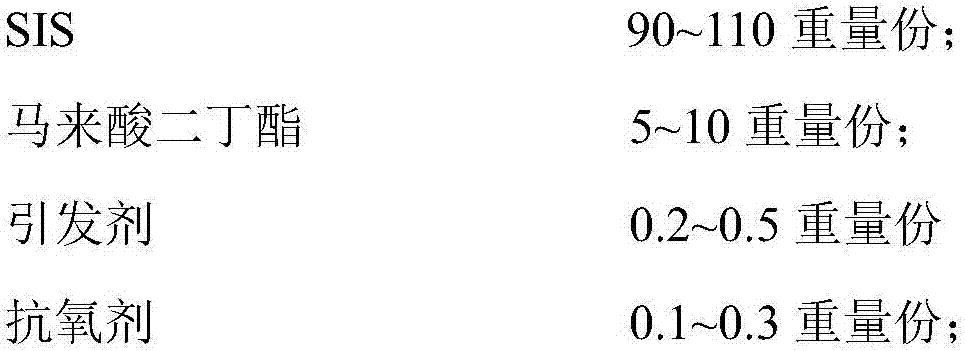

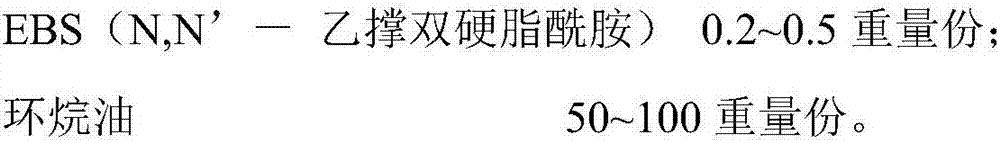

[0021]

[0022] The preparation method of the above reaction extrusion functionalized SIS material is prepared through the following steps:

[0023] Add SIS and naphthenic oil to the first hopper of a twin-screw extruder with a screw length-to-diameter ratio of 48:1, and add the initiator and dibutyl maleate to a twin-screw extruder with a length-to-diameter ratio of 48:1 In the second hopper, antioxidant 1010 and EBS are added to the third hopper of the twin-screw extruder with aspect ratio 48:1, the screw speed is 30-50 rpm, the distance between the second hopper and the first hopper The ratio to the total length of the screw is 20:48, the ratio of the distance between the third hopper and the second hopper to the total length of the screw is 10:48, and the temperature setting of the twin-screw extruder is shown in Table 1 below:

[0024] Table 1

[0025]

[0026] 100 parts by weight of the reaction extrusion functionalized SIS material obtained by the method of Examp...

Embodiment 2

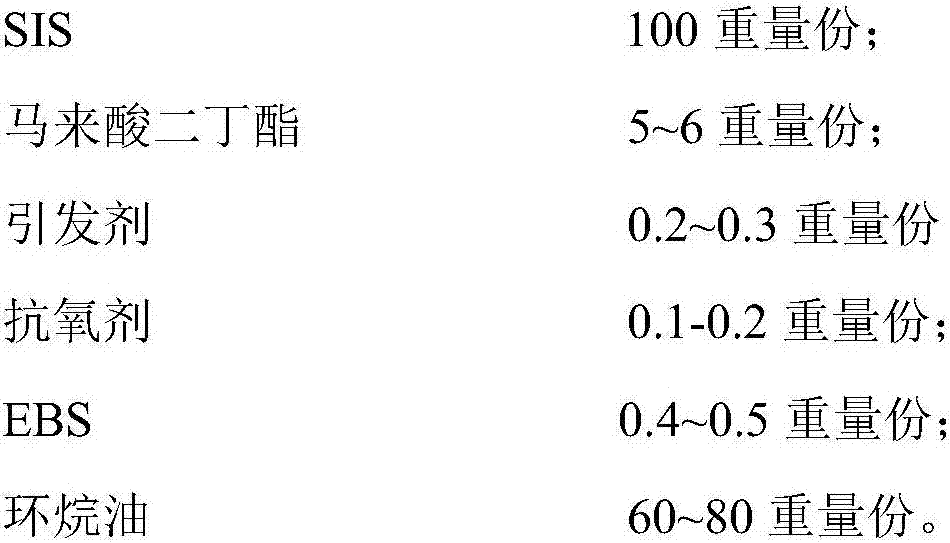

[0032]

[0033] The preparation method of the above reaction extrusion functionalized SIS material is prepared through the following steps:

[0034] Add SIS and naphthenic oil to the first hopper of a twin-screw extruder with a screw length-to-diameter ratio of 48:1, and add the initiator and dibutyl maleate to a twin-screw extruder with a length-to-diameter ratio of 48:1 In the second hopper, antioxidant and EBS are added in the third hopper of the twin-screw extruder with aspect ratio 48:1, the screw speed is 30-50 rpm, the distance between the second hopper and the first hopper is the same as The ratio of the total length of the screw is 20:48, the ratio of the distance between the third hopper and the second hopper to the total length of the screw is 10:48, and the temperature setting of the twin-screw extruder is shown in Table 3 below:

[0035] table 3

[0036]

[0037] 100 parts by weight of the reaction extrusion functionalized SIS material obtained by the metho...

Embodiment 3

[0043]

[0044] The preparation method of the above reaction extrusion functionalized SIS material is prepared through the following steps:

[0045] Add SIS and naphthenic oil to the first hopper of a twin-screw extruder with a screw length-to-diameter ratio of 48:1, and add the initiator and dibutyl maleate to a twin-screw extruder with a length-to-diameter ratio of 48:1 In the second hopper, antioxidant and EBS are added in the third hopper of the twin-screw extruder with aspect ratio 48:1, the screw speed is 30-50 rpm, the distance between the second hopper and the first hopper is the same as The ratio of the total length of the screw is 20:48, the ratio of the distance between the third hopper and the second hopper to the total length of the screw is 10:48, and the temperature setting of the twin-screw extruder is shown in Table 5 below:

[0046] table 5

[0047]

[0048] 100 parts by weight of the reaction extrusion functionalized SIS material obtained by the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com