Novel environment-friendly material thermoplastic eutectic

An environmentally friendly material and thermoplastic technology, applied in the formulation and manufacturing process of thermoplastic eutectic, a new multifunctional environmentally friendly material, can solve the problems of white pollution and achieve the effect of solving the problem of white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1: Blown film made of plastic eutectic, cast film (note: plastic eutectic for soft products), composition is 55% ultrafine zeolite powder or ultrafine diatomite powder (both can be used) It can be used alone or in any proportion), 3% high-carbon linking agent, 10% thermoplastic elastomer, 10% metallocene linear low-density polyethylene, 15% high-density polyethylene or low-density polyethylene (note: select High-density polyethylene or low-density polyethylene depends on the nature of the product), 7% polypropylene.

example 2

[0021] Example 2: Injection-molded products made of plastic eutectics (note: plastic eutectics for neutral products), the composition is 65% ultrafine zeolite powder or ultrafine diatomite or any ratio of the two, 4% higher Carbon Link Agent, 10% Thermoplastic Elastomer, 11% HDPE, 10% Polypropylene.

example 3

[0022] Example 3: Plastic eutectics are used to make plates and pipe products (note: they are plastic eutectics for hard products), and the ingredients are composed of 75% ultrafine zeolite powder or ultrafine diatomite powder, or any ratio of the two, 5% high carbon linking agent, 5% thermoplastic elastomer, 5% polypropylene, 10% high density polyethylene.

[0023] Example formula ratio table, as follows:

[0024] sexual order

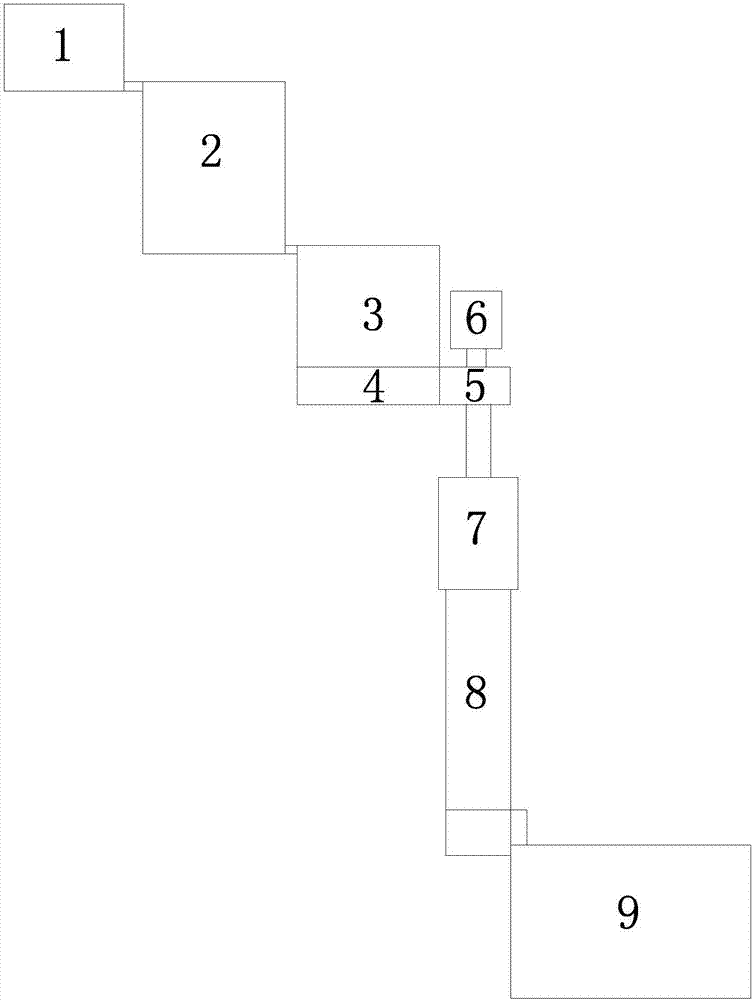

[0025] Such as figure 1 As shown, a new environmentally friendly material thermoplastic eutectic manufacturing process, the specific steps are as follows: (1) first carry out thermal cycle drying; put the ultrafine porous inorganic powder into the mixing dryer 1 (note: mixing drying Dryer 1 is heated by an electric ceramic heater), and keeps running at a medium-low speed; mixing in dynamic and gradual temperature rise, colliding with self-friction, so that the moisture in the microporous inorganic powder gradually evaporates until the moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com