A kind of super high-strength bulletproof steel plate and preparation method thereof

A strong anti-bullet steel plate, ultra-high technology, applied in the field of steel plate production, can solve the problems of easy cracking when bending, poor cold forming performance of bullet-proof steel plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

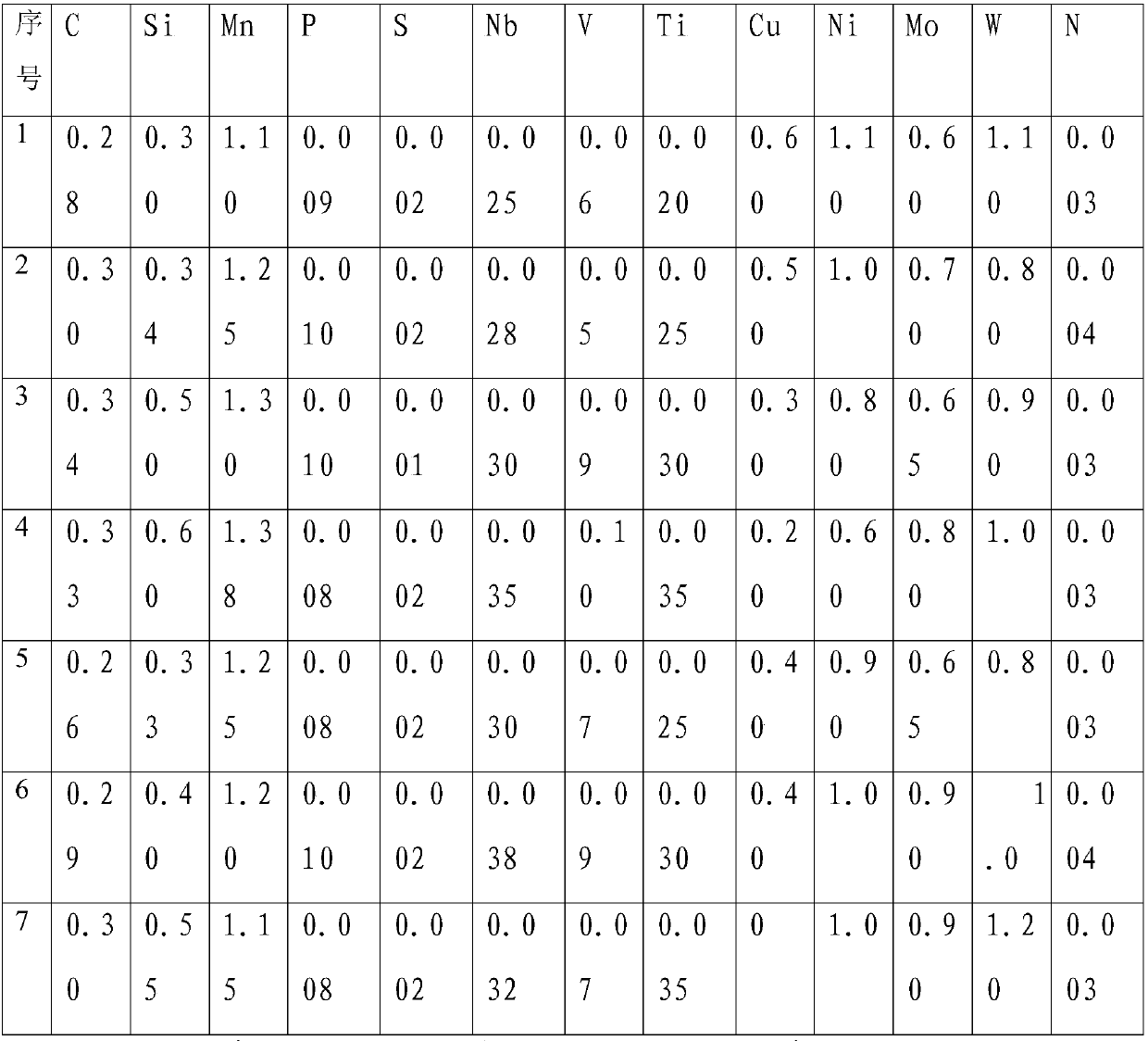

[0036] Another aspect of the present invention provides a method for producing the above-mentioned ultra-high-strength bulletproof steel plate, comprising the following steps:

[0037] Step 1, the molten iron is smelted in a converter or an electric furnace, LF refined or RH refined to obtain molten steel with the composition described in claim 1, and then continuously cast to obtain a slab.

[0038] Step 2, reheating the billet in a heating furnace, and then rough rolling and finish rolling to obtain a hot-rolled plate.

[0039] In step 3, the hot-rolled sheet is subjected to laminar flow cooling, and then rolled into a coil to obtain a steel coil.

[0040] In step 4, the steel coil is slowly cooled, and then subjected to continuous heat treatment to obtain a finished product.

[0041] Among them, the specific process parameters are controlled as follows:

[0042] The casting slab is heated to 1240-1280°C in the heating furnace, and the heating time is more than 210 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com