Optimized supporting wheel type robot for detecting insides of pipes

A robot and pipeline technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of pipeline detection accuracy limitation, large friction and wear, large vibration, etc., and achieve strong adaptability to the inner diameter of the pipeline, small vibration and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

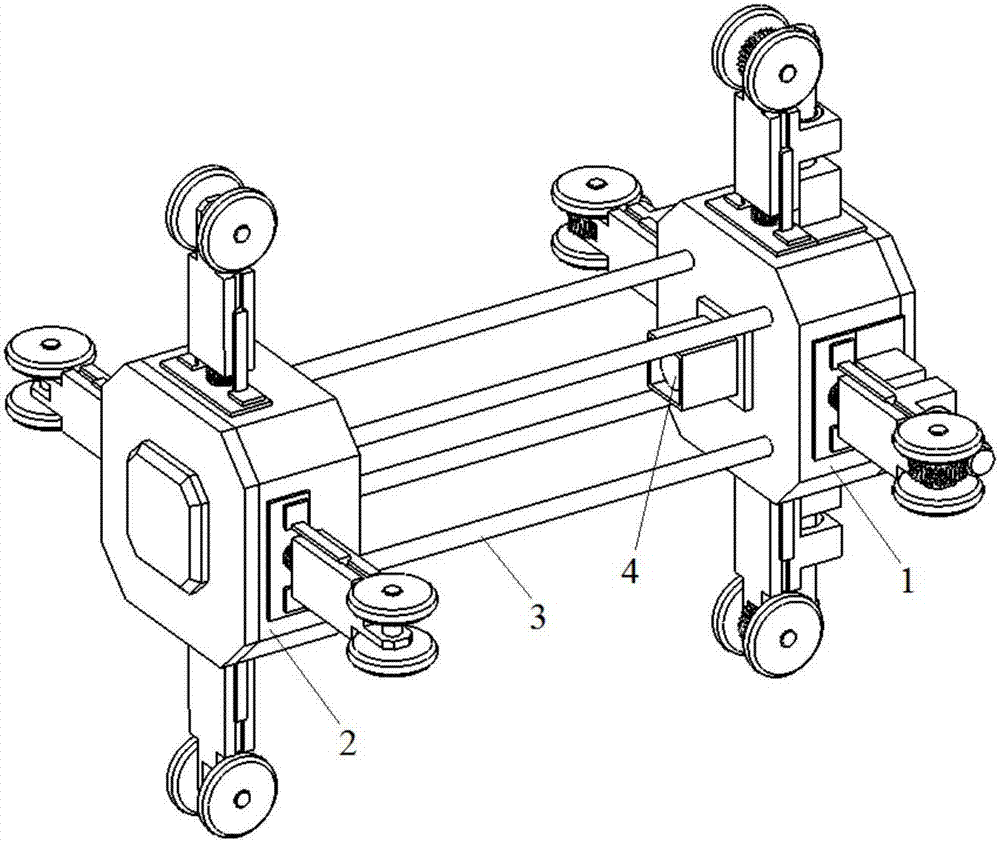

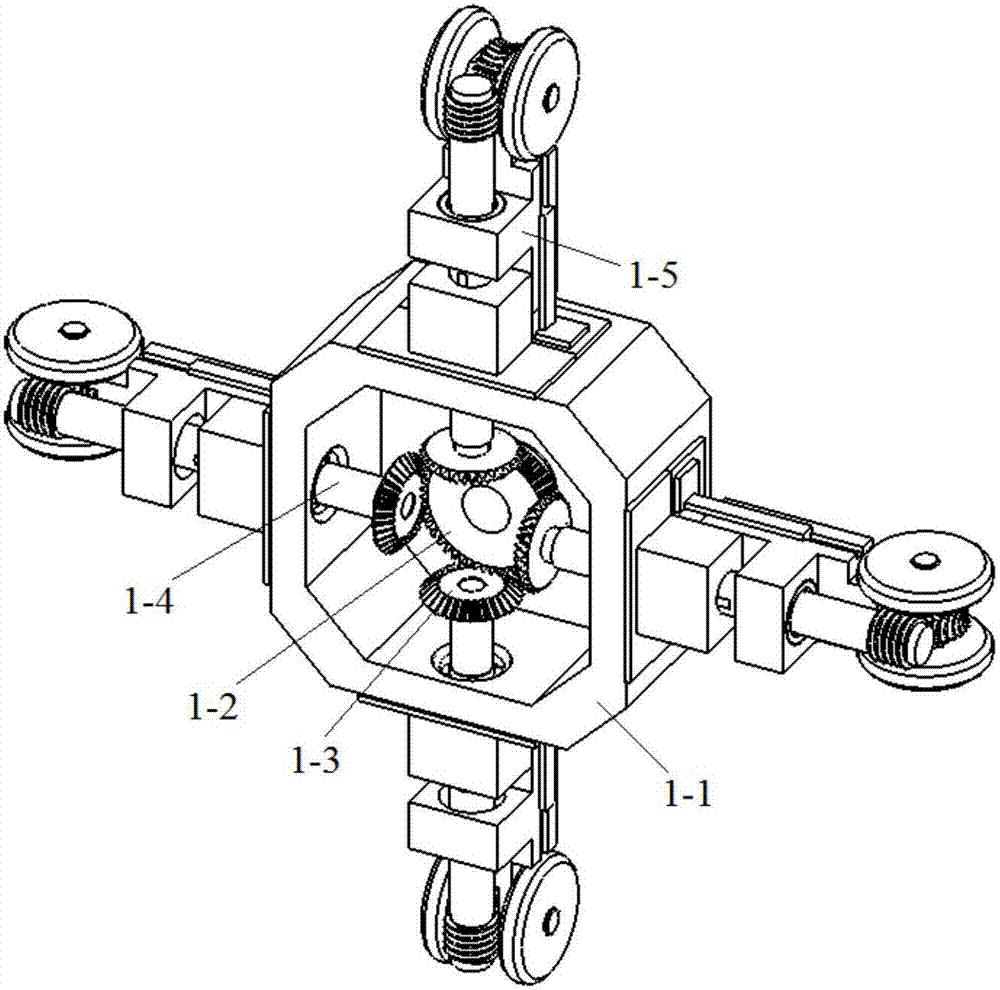

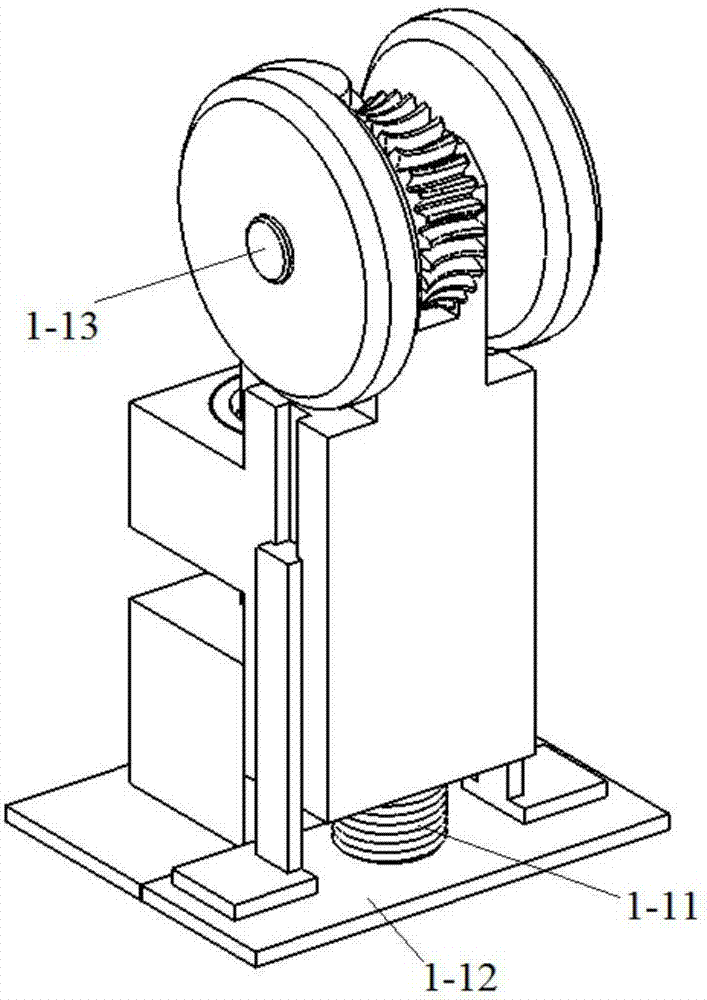

[0021] combine Figure 1 to Figure 7 , the present invention includes front body, rear body, intermediate connecting rod, motor and other components. The front body of the present invention, the motor is installed in the motor seat, fixedly installed on the frame of the front body, through the bearing, the large bevel gear shaft, the power is transmitted to the large bevel gear, the large bevel gear meshes with the small bevel gear, and the small bevel gear The gear shaft is docked with the worm through the bearing, which drives the worm to rotate synchronously, and drives the worm gear installed coaxially with the two rollers to rotate to realize the entire power transmission of the front body. The support wheel mounting seat and the body frame are adjusted by springs to adapt to the Different pipe inner diameters; the rear body mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com