Precision speed reducer static performance test bench

A precision reducer, static performance technology, applied in the testing of machine/structural components, machine gear/transmission mechanism testing, testing of mechanical components, etc., can solve the problem of not being able to eliminate test errors, not specifying test brackets, and not being able to measure torsional stiffness and other problems, to achieve the effect of improving test accuracy and test efficiency, good test stability and wide test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

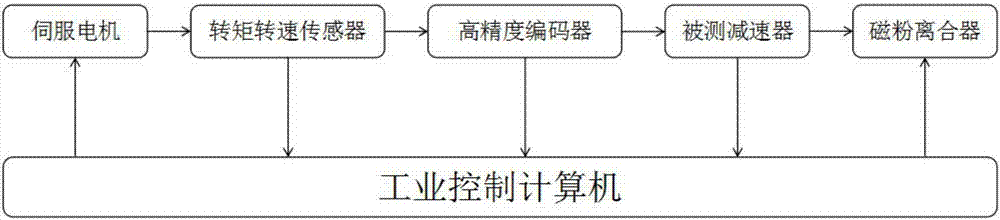

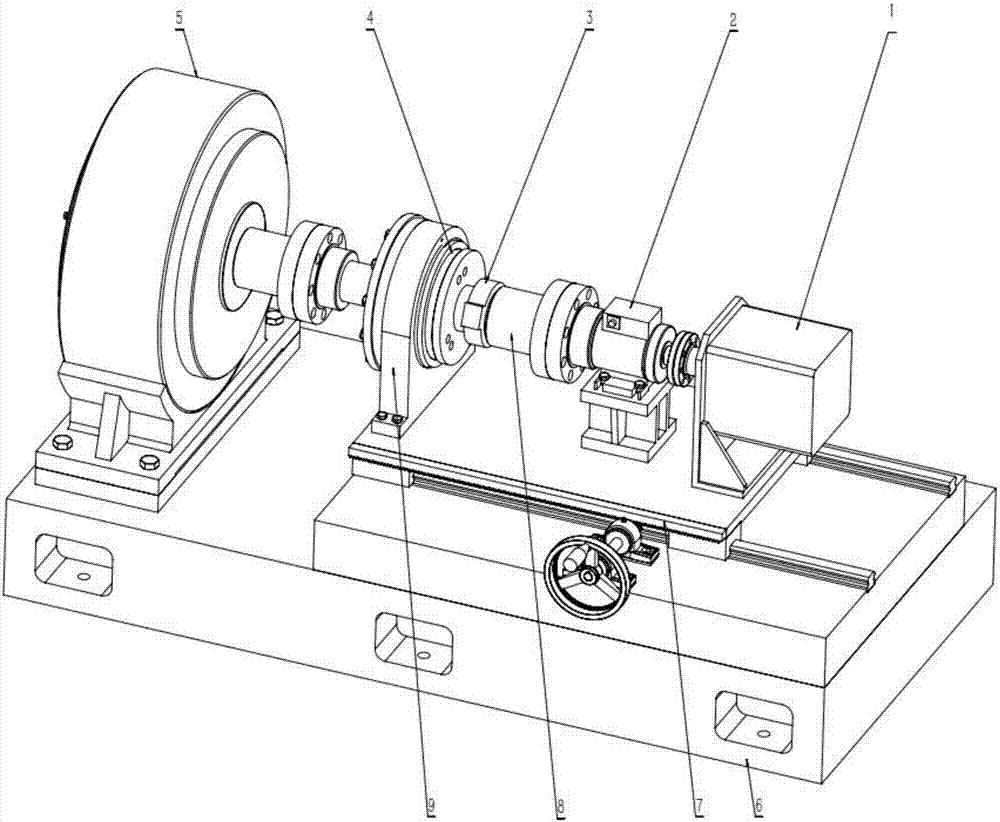

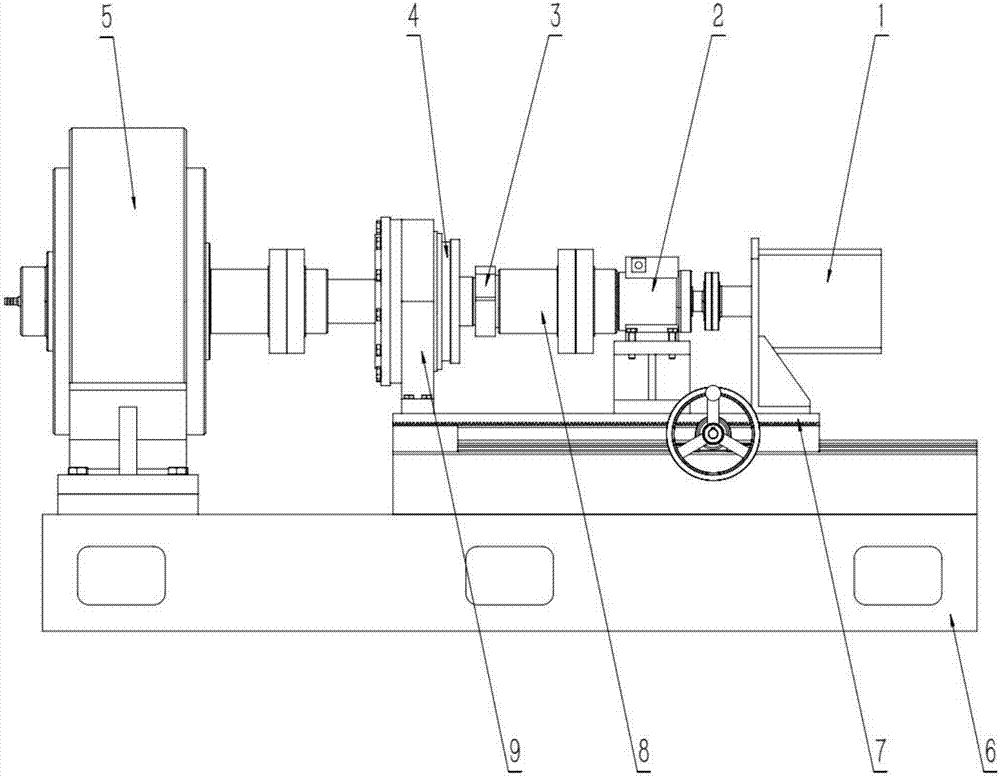

[0022] Such as figure 1 , figure 2 , image 3 As shown, the precision reducer static performance test bench provided by the present invention consists of a servo motor 1, a torque speed sensor 2, a high-precision encoder 3, a measured reducer 4, the main components of a magnetic powder clutch 5 and a base 6, The horizontal slide table 7, the coupling 8, the reducer mounting seat 9 and other auxiliary components are connected and fixed, and it is characterized in that: the servo motor 1 is connected with the output shaft of the measured reducer 4 through the torque torque sensor 2, so The high-precision encoder 3 is installed on the output shaft of the tested reducer 4, and the high-precision encoder 3 is used to read the angle information of the output end of the tested reducer 4. The magnetic powder clutch 5 and the tested reducer 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com