Industrial robot speed reducer torsion rigidity testing stand

An industrial robot and torsional stiffness technology, which is applied in the testing of machine gear/transmission mechanism, the testing of machine/structural components, and the testing of mechanical components, etc. It can solve the problems of taking up too much space, scattered test benches, and large test benches. , to achieve the effect of high degree of automation, easy replacement, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

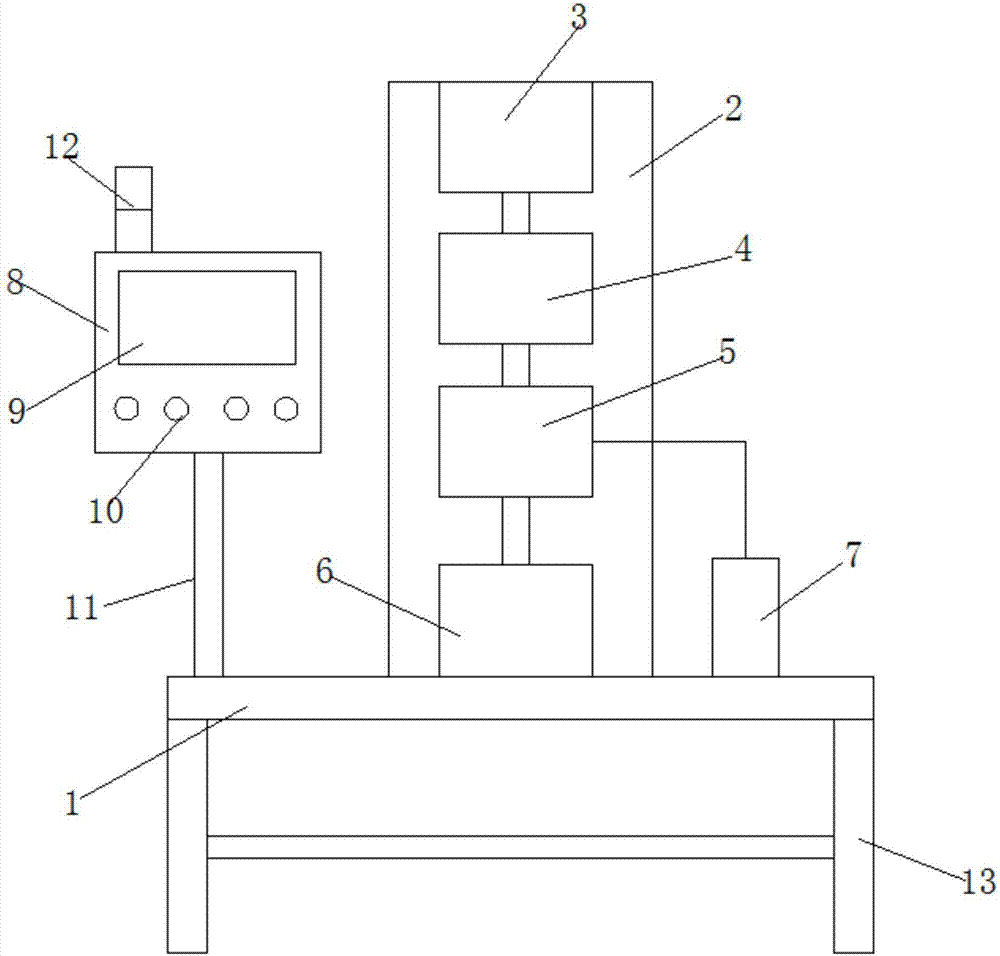

[0023] Such as figure 1 As shown, an industrial robot reducer torsional rigidity test bench includes a support platform 1, a vertical plate 2, a drive motor 3, an electric dynamometer 6, a reducer 4, a torsion sensor 5, a circular grating 7 and a controller 8. The vertical plate 2 is installed on the upper side of the support platform 1, and the driving motor 3, the reducer 4, the torsion sensor 5 and the electric dynamometer 6 are installed on the vertical plate 2 in sequence from top to bottom. The central shaft is connected to the reducer 4, the reducer 4 is connected to the torsion sensor 5 through the coupling, the torsion sensor 5 is connected to the electric dynamometer 6 through the coupling, and the torsion sensor 5 is connected to the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com