QFN chip

A chip and chip body technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as poor welding, small contact area, and substandard coverage, and achieve the effect of improving bonding force and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

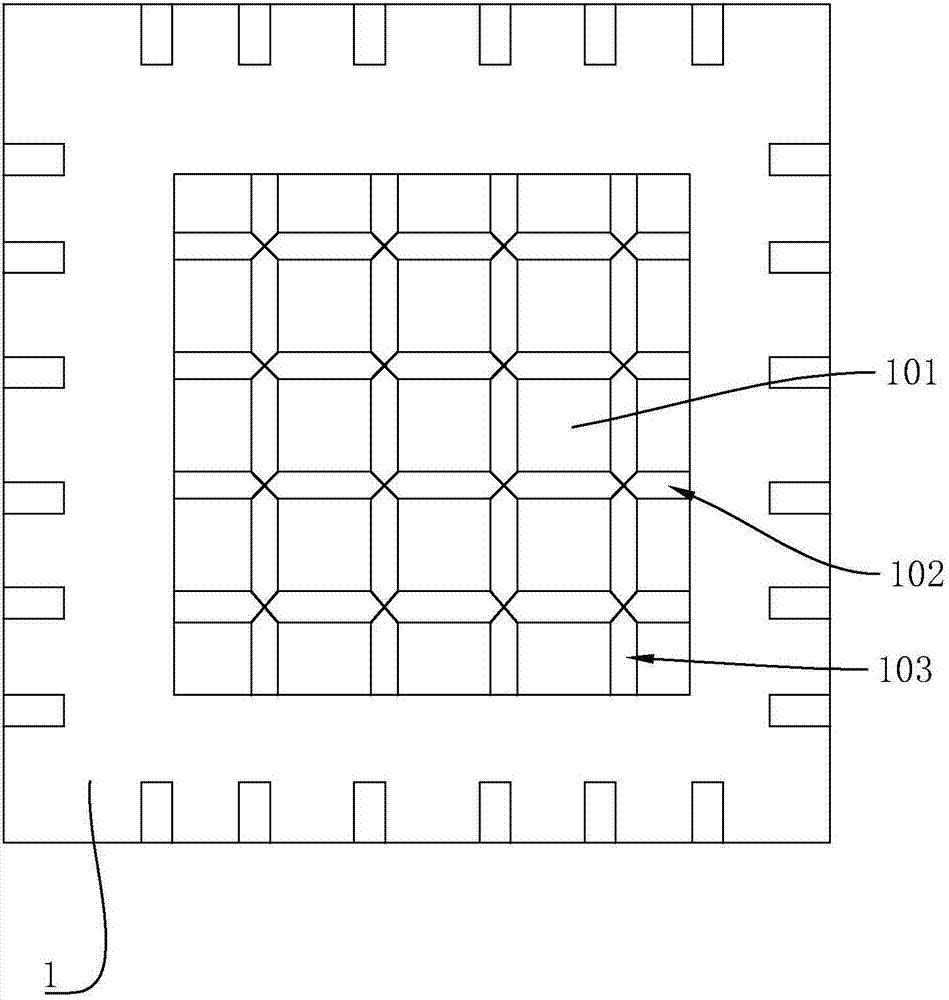

[0029] Such as figure 1 Shown, a kind of QFN chip comprises chip body 1, and this chip body 1 is provided with pad 101, and this pad 101 is provided with a plurality of transverse tin-conducting grooves 102 and a plurality of vertical tin-conducting grooves 103, and the The transverse tin-conducting grooves 102 and the longitudinal tin-conducting grooves 103 are arranged to cross each other and communicate with each other.

[0030] Preferably, all the transverse tin-conducting grooves 102 and all the longitudinal tin-conducting grooves 103 are arranged perpendicular to each other; The pads 101 are arranged in an array along the length direction.

[0031] The distance between two adjacent horizontal tin-conducting grooves 102 is equal to the distance between two adjacent vertical tin-conducting grooves 103 , and the width of the transverse tin-conducting grooves 102 is the same as the width of the longitudinal tin-conducting grooves 103 .

Embodiment 2

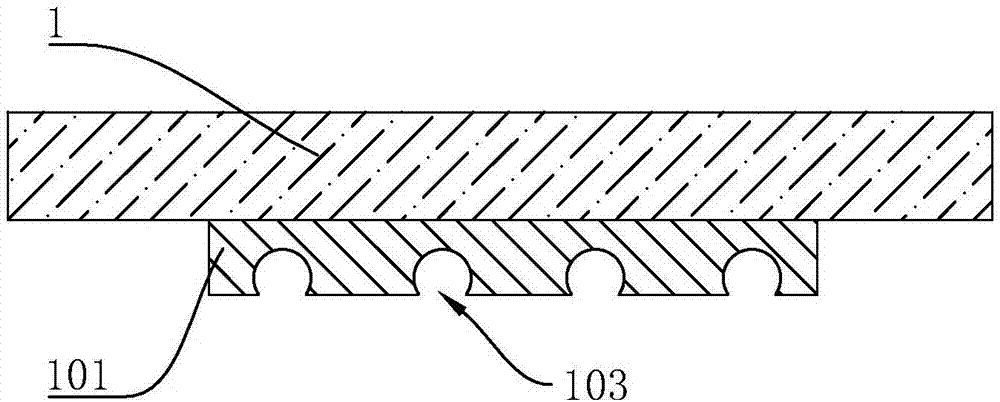

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that both the transverse tin-conducting groove 102 and the longitudinal tin-conducting groove 103 are omega grooves (see figure 2 ).

Embodiment 3

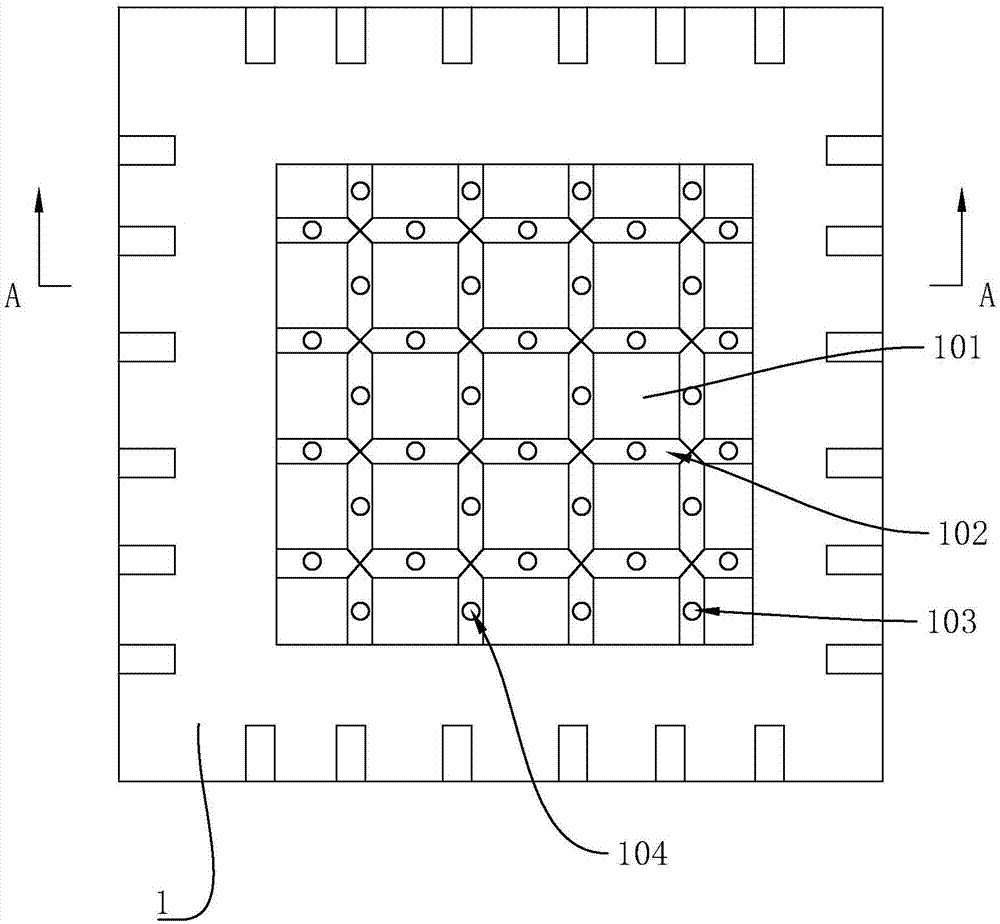

[0035] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that at least one concave hole 104 is provided on the pad 101 corresponding to the horizontal tin-conducting groove 102 and the vertical tin-conducting groove 103, and the concave hole 104 is along the The height direction of the pad 101 extends, and the concave hole 104 communicates with the transverse tin-conducting groove 102 or the longitudinal tin-conducting groove 103 (see image 3 and Figure 4 ). In this scheme, each concave hole 104 located in the horizontal tin-conducting groove 102 and the longitudinal tin-conducting groove 103 corresponds to a small pad (the small pad is formed by the horizontal tin-conducting groove 102 and the vertical tin-conducting groove 102). The groove 103 divides the pad 101).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com