Cleaning machine of experimental animal feeding box

A technology for laboratory animals and washing machines, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cleaning dead corners, wasting time and manpower and material resources, difficult to clean thoroughly, etc., to meet the cleaning effect, The effect of ensuring cleaning effect and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

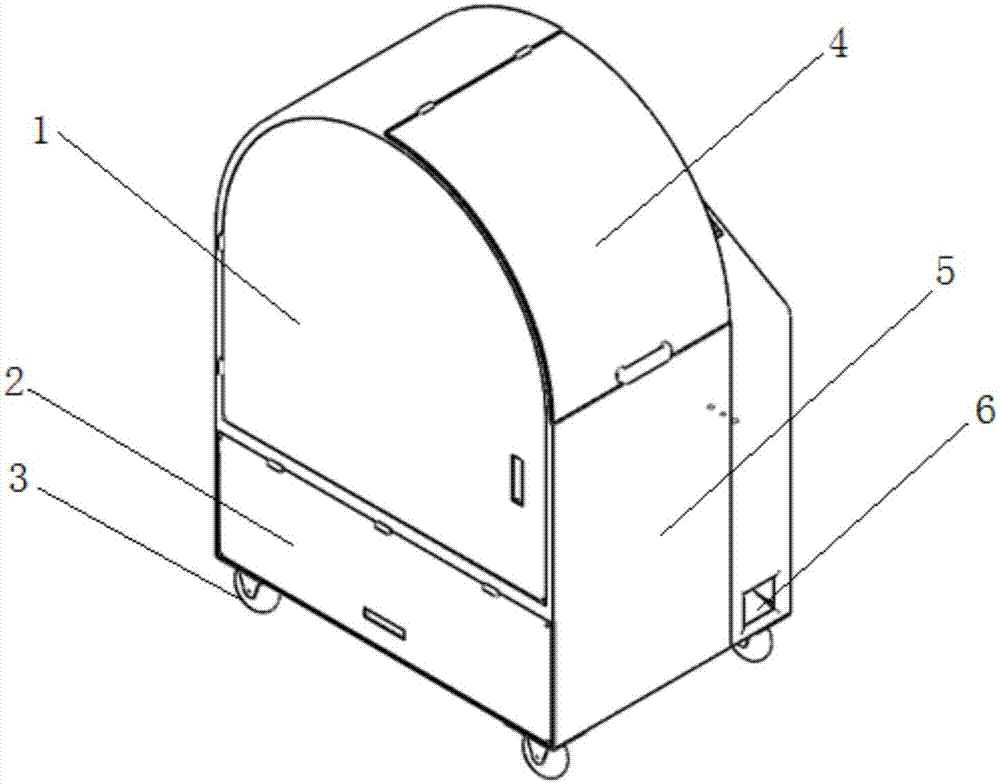

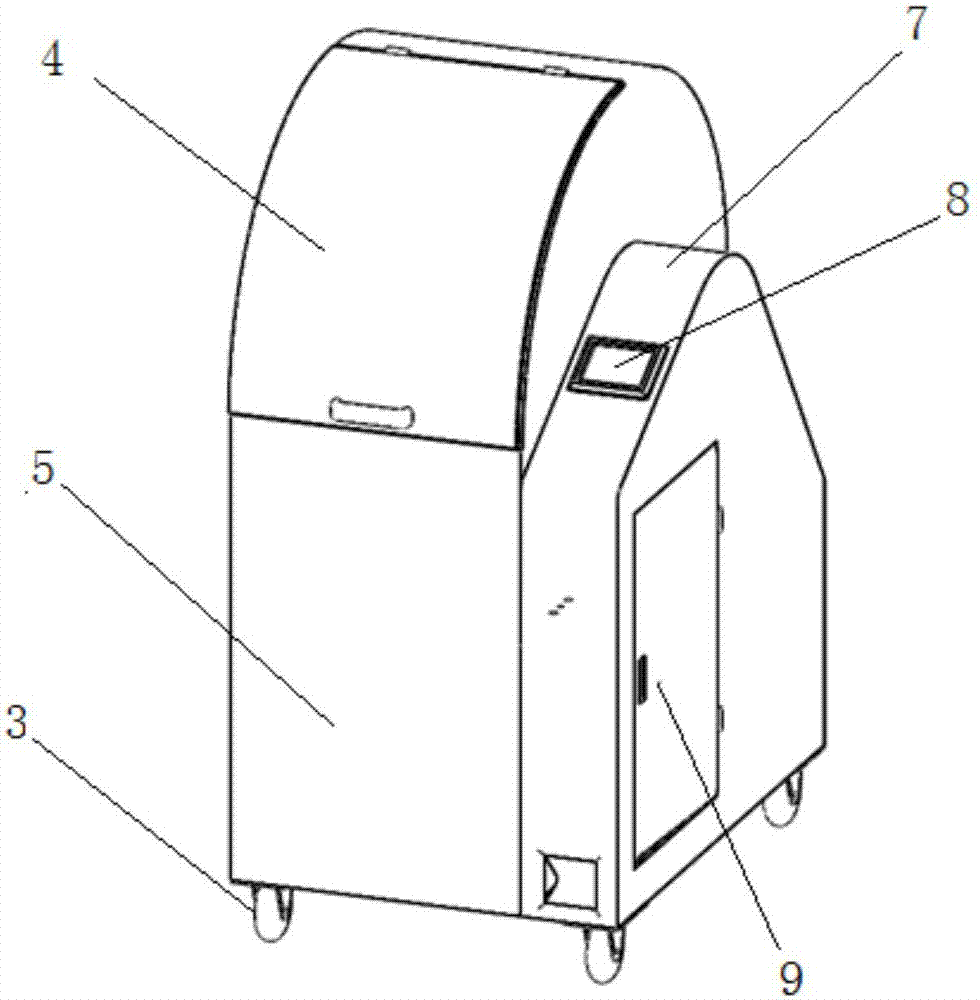

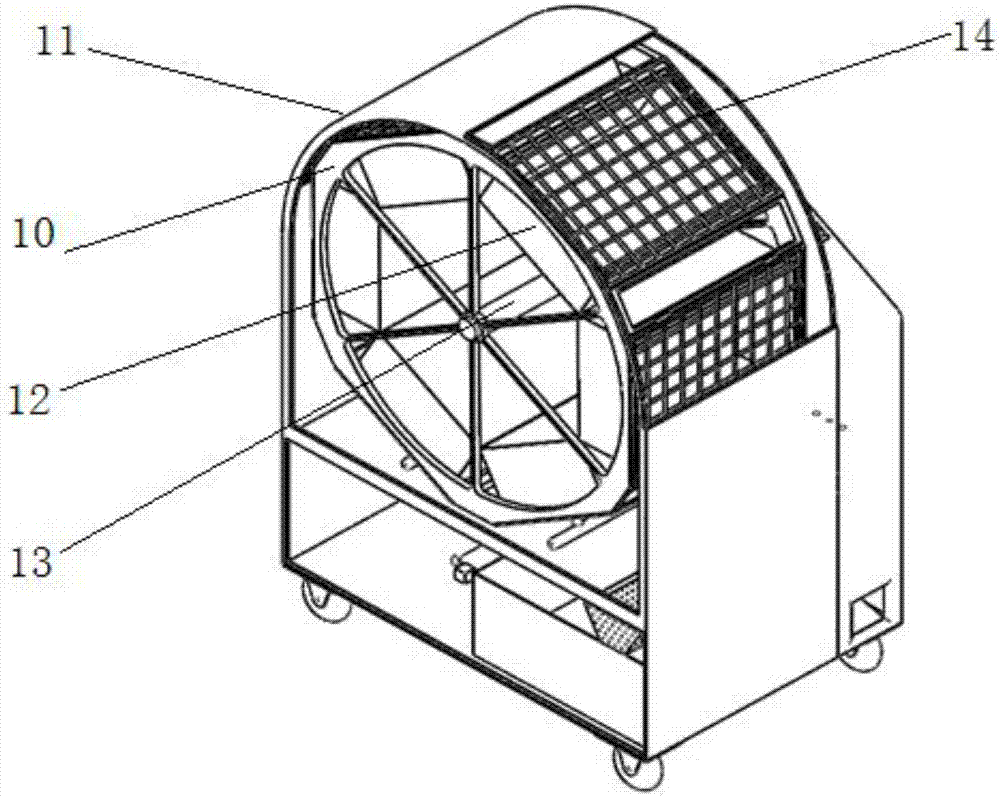

[0040] The cleaning machine for the experimental animal breeding box disclosed by the present invention comprises a cleaning machine main body 5, the upper part of the cleaning machine main body 5 is a cleaning cabin 1, and the lower part is a filter liquid storage cabin 2, and one side of the cleaning machine main body 5 is also provided with an electrical cabin 7. The cabin 7 is provided with a servo motor and a control circuit board for controlling the work of the servo motor; the cleaning cabin 1 includes a cage roller 10 and a fixed shaft 13, the fixed shaft 13 is fixed on the inner wall of the cleaning cabin 1, and the cage roller 10 is installed on the On the fixed shaft 13 and can rotate around the fixed shaft 13 under the drive of the servo motor, several cage box 12 installation stations are provided on the cage box roller frame 10; The nozzles are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com