Special machine tool with multi-station mechanical arms

A technology of special-purpose machine tools and manipulators, which is applied in the field of machine tools, can solve problems such as insufficient use of the workshop area, large space occupied by machine tools, and affecting processing efficiency, so as to save manpower, reduce processing costs, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

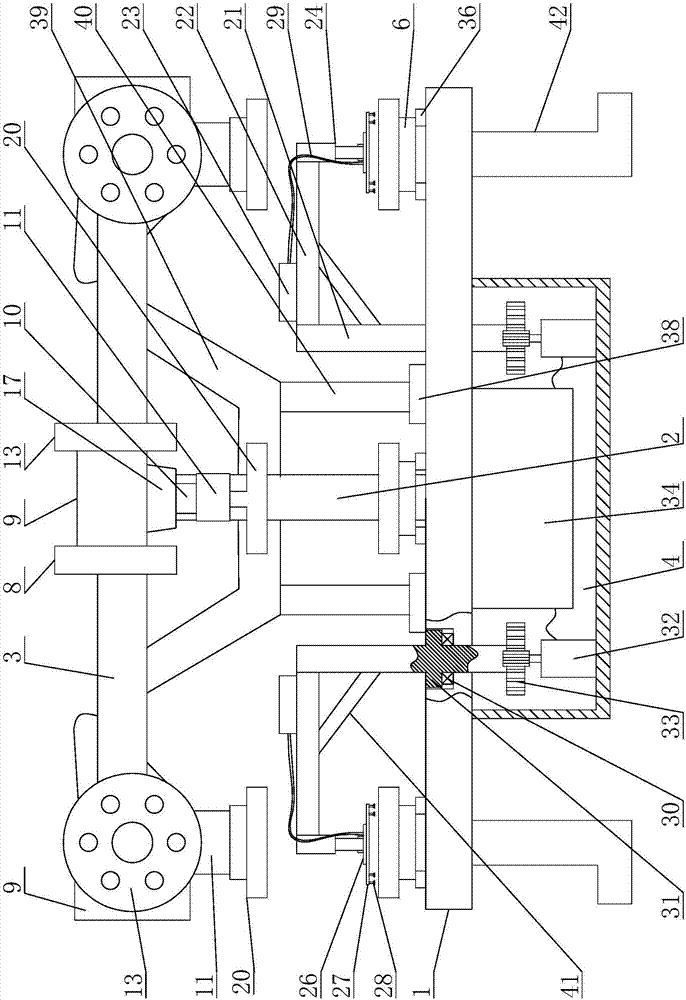

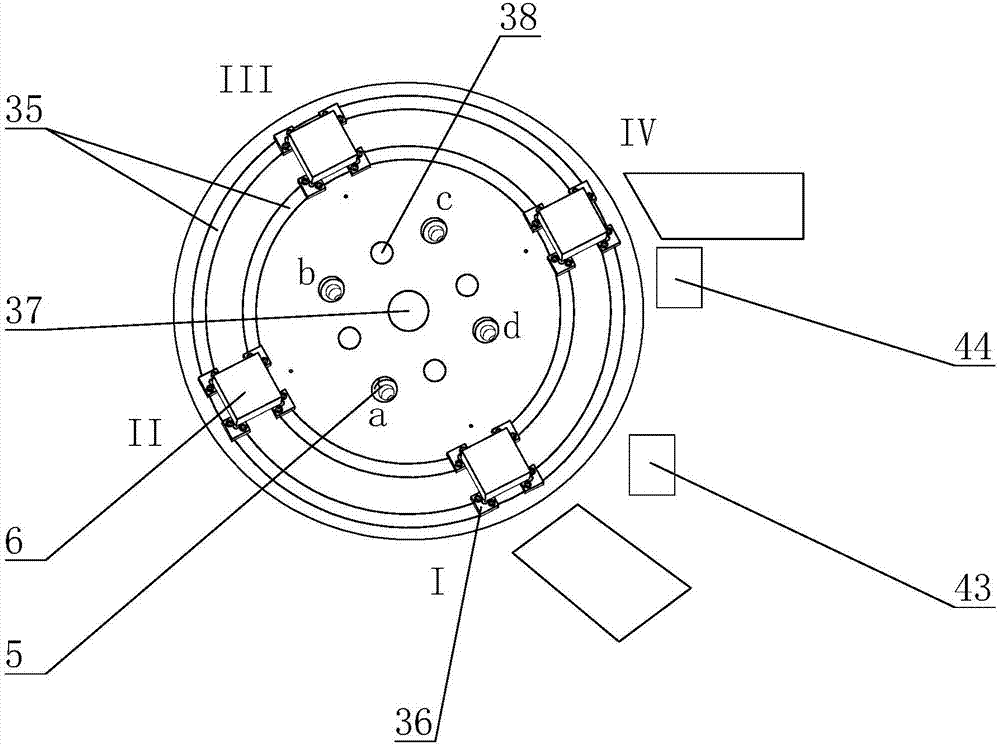

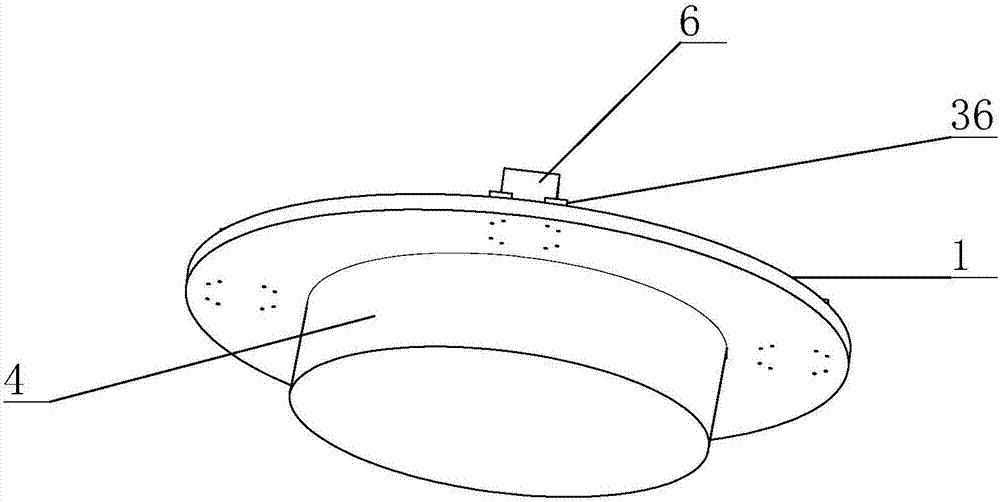

[0033] The present invention is a special-purpose machine tool with a multi-station manipulator. The main structure includes a workbench 1, a vertical support column 2, a lateral support column 3, a stamping device assembly, a station manipulator device assembly, and a control room 4. The workbench 1 is provided with 4 processing stations and 4 transmission communicating holes 5, and the 4 processing stations are respectively No. I station, No. II station, No. III station, and No. IV station. The transmission communication holes 5 are respectively the transmission communication holes 5 of part a, the transmission communication holes 5 of part b, the transmission communication holes 5 of part c, and the transmission communication holes 5 of part d. Each processing station is provided with a lower mold body fixing seat 6. The bottom of the vertical support column 2 is fixed at the center of the workbench 1, and there are four horizontal support columns 3. One end of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com