Aeration system

An aeration system and aeration technology, applied in water treatment parameter control, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of high production cost and poor sewage treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

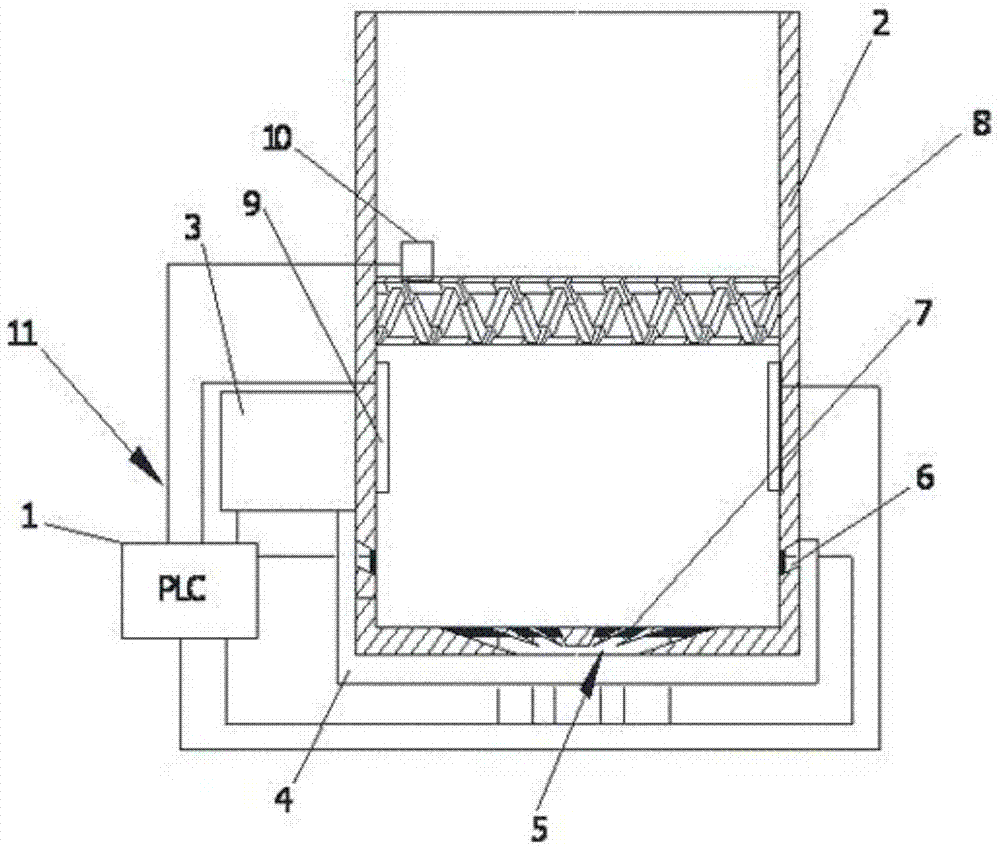

[0012] see figure 1 As shown, an aeration system of the present invention includes a PLC controller 1, an aeration tank 2, an aerator 3 arranged outside the aeration tank 2, and the aerator 3 is connected with an aeration tank extending to the inside of the aeration tank 2. The air pipeline 4 and the aeration pipeline 4 include a plurality of wind-cut aeration ends 5 and a plurality of edge-wise aeration ends 6, and the plurality of wind-cut aeration ends 5 are evenly arranged in the bottom end of the aeration tank 2, each A wind-cut aeration end 5 is a fan-shaped structure, and the acute angle formed between the plane and the horizontal plane is an included angle between 50° and 75°, and the wind-cut aeration end can be distributed through fan-shaped diffusion The air flow is uniformly and fully distributed into the aeration tank; a plurality of edge aeration ends 6 are located at the radial circumferential position of the inner wall of the aeration tank 2, and the edge aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com