A method for preparing temperature-responsive surfaces based on self-polymerization of dopamine

A temperature-responsive, self-polymerizing technology, applied in the direction of adhesives, etc., can solve the problems of temperature-responsive surface, such as poor stability in use, complicated operation, and limited substrates, and achieve the effects of wide applicability, simple operation, and overcoming complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

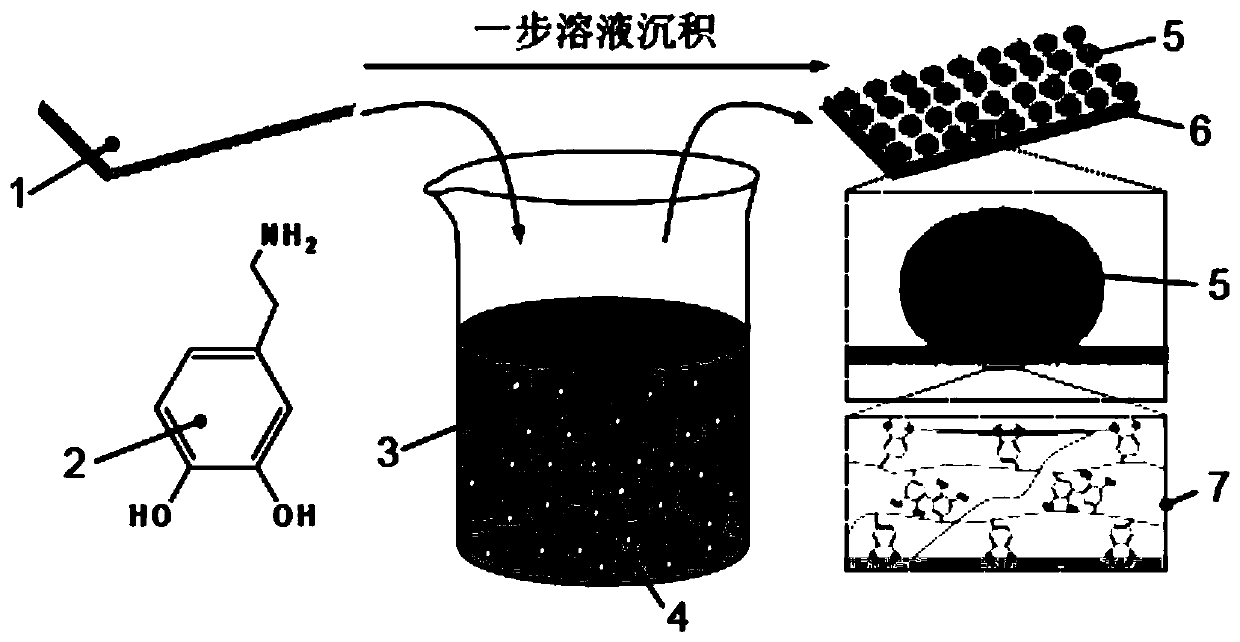

[0044] In this example, the schematic flow chart for preparing a temperature-responsive surface is as follows figure 1 As shown, the steps are as follows:

[0045] (1) Using the glass capillary as the base material, the glass capillary is ultrasonically cleaned with acetone, ethanol and deionized water in order to remove organic pollutants and solid particles on the surface of the glass capillary to obtain a clean glass capillary, and clean the glass capillary Soak in deionized water for later use.

[0046] (2) Configure Tris buffer solution: add Tris (Tris) into secondary deionized water and stir to form a Tris solution evenly. When the pH value reaches 8.5, Tris buffer solution is obtained.

[0047] Add the PNIPAM nanogel particles into the Tris buffer at a temperature of 25°C according to the mass ratio of the PNIPAM nanogel particles to the Tris buffer at a ratio of 1:200, and ultrasonically disperse the nanogel particles evenly at a power of 40W for 20min. Obtain the n...

Embodiment 2

[0058] In this example, the schematic flow chart for preparing a temperature-responsive surface is as follows figure 1 As shown, the steps are as follows:

[0059] (1) Using a glass plate as the base material, the base material is ultrasonically cleaned with acetone, ethanol and deionized water in order to remove solid particles on the surface of the base material to obtain a clean base material, which is soaked in deionized water ready for use.

[0060] (2) Configure Tris buffer: Add Tris to secondary deionized water and stir to form a Tris solution. The concentration of the Tris solution is 10mmol / L. Slowly add dilute hydrochloric acid to the Tris solution to adjust its pH to 7 to obtain Tris buffer. liquid.

[0061] Add the PNIPAM nanogel particles into the Tris buffer at a temperature of 20°C according to the mass ratio of the PNIPAM nanogel particles to the Tris buffer at a ratio of 1:100, and ultrasonically disperse the nanogel particles evenly at a power of 50W for 10...

Embodiment 3

[0065] In this example, the schematic flow chart for preparing a temperature-responsive surface is as follows figure 1 As shown, the steps are as follows:

[0066] (1) Using a polydimethylsiloxane flat plate as the base material, the base material is ultrasonically cleaned with deionized water to remove solid particles on the surface of the base material to obtain a clean base material, and soak the cleaned base material in deionized water. ions ready for use.

[0067] (2) Configure Tris buffer: Add Tris to secondary deionized water and stir to form a Tris solution. The concentration of the Tris solution is 20mmol / L. Slowly add dilute hydrochloric acid to the Tris solution to adjust its pH to 10 to obtain Tris buffer. liquid.

[0068] The PNIPAM nanogel particles are added into the Tris buffer at a temperature of 23°C at a ratio of 1:500 according to the mass ratio of the PNIPAM nanogel particles to the Tris buffer, and the nanogel particles are evenly dispersed at a power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com