Antistatic natural rubber and preparation method thereof

A natural rubber and antistatic technology, which is applied in the field of antistatic natural rubber and its preparation, can solve the problems of large proportion of metal plating on the surface of particles, unsuitability for the preparation of conductive materials, and unsuitability, and achieve high conductivity and mild reduction conditions , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

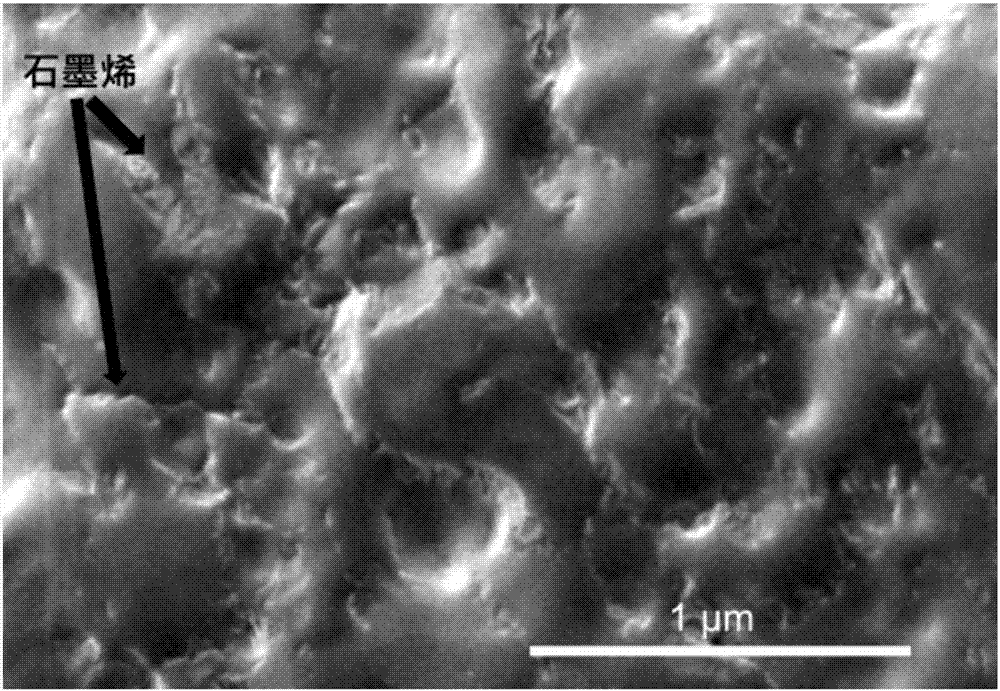

Image

Examples

preparation example Construction

[0018] A method for preparing antistatic natural rubber, comprising: mixing graphene oxide with a weight ratio of 1:5-1000 and water to obtain a graphene oxide suspension.

[0019] In the embodiment of the present invention, the first ultrasonic treatment is performed after the graphene oxide is mixed with water. After the first ultrasonic treatment, the graphene oxide and water can be mixed better to obtain a uniform suspension. In the embodiment of the present invention, the ultrasonic power of the first ultrasonic treatment is 50-500 W, and the ultrasonic time is 2-60 min. In addition, preferably, after the graphene oxide is mixed with water, the temperature is controlled within the range of 20-80° C., and the first ultrasonic treatment is performed after magnetic stirring for 10-50 min. In this way, the graphene oxide can be fully infiltrated, which is favorable for mixing with water uniformly.

[0020] In the embodiment of the present invention, the graphene oxide can b...

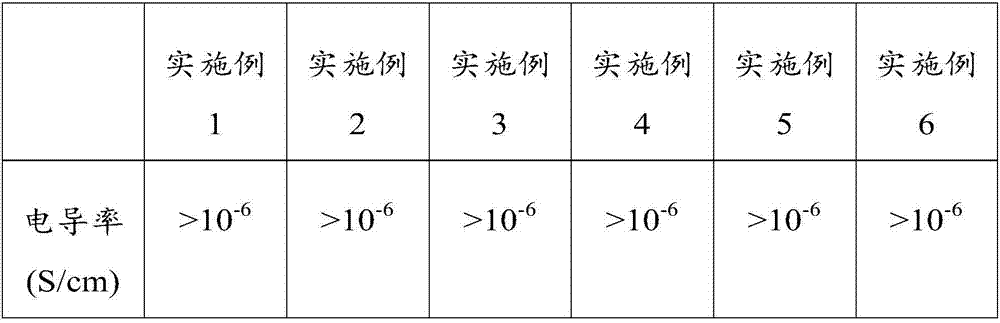

Embodiment 1

[0037] A kind of antistatic natural rubber, the preparation method of this antistatic natural rubber comprises:

[0038] The graphene oxide with a weight ratio of 1:100 was mixed with water in a beaker, the temperature was controlled at 20 °C, and after magnetic stirring for 30 min, the graphene oxide suspension was obtained by ultrasonic treatment for 15 min under the power condition of 100 W.

[0039] Mix the peregal solution with a mass concentration of 10% and a fresh natural latex with a mass concentration of 45%, and then quickly pour acetic acid with a mass concentration of 3.85% until the pH of the system is 2.4, and magnetically stir to obtain a cationic natural latex. . Wherein the weight ratio of the peregalin O-30 in the peregalin solution and the dry rubber in the fresh natural latex is 1:50.

[0040] The graphene oxide suspension and the cationic natural latex were mixed in a ratio of 1:1 by weight, and then ultrasonically treated for 50 min at a power of 50W to...

Embodiment 2

[0045] A kind of antistatic natural rubber, the preparation method of this antistatic natural rubber comprises:

[0046] The graphene oxide with a weight ratio of 1:20 was mixed with water in a beaker, the temperature was controlled at 30 °C, and after magnetic stirring for 45 min, the graphene oxide suspension was obtained by ultrasonic treatment for 60 min under the power condition of 80 W.

[0047] Mix the peregal solution with a mass concentration of 20% and a fresh natural latex with a mass concentration of 30%, and then quickly pour formic acid with a mass concentration of 2% until the pH value of the system is 2.5, and magnetically stir to obtain a cationic natural latex. . Wherein the weight ratio of the peregalin O-30 in the peregalin solution to the dry rubber in the fresh natural latex is 3:100.

[0048] The graphene oxide suspension and the cationic natural latex were mixed in a ratio of 1:1 by weight, and then ultrasonically treated for 50 min at a power of 50W t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com